1. Importance of Density Meter Calibration Density meters are widely used in petroleum refining, chemical manufacturing, food and beverage production, and pharmaceutical industries for process control and quality assurance. The accuracy and reliability of these instruments directly impact product quality and operational stability. Thus, regular calibration and verification are critical to ensure dependable measurement results.

2. Working Principles of Density Meters Density meters operate mainly based on two principles:

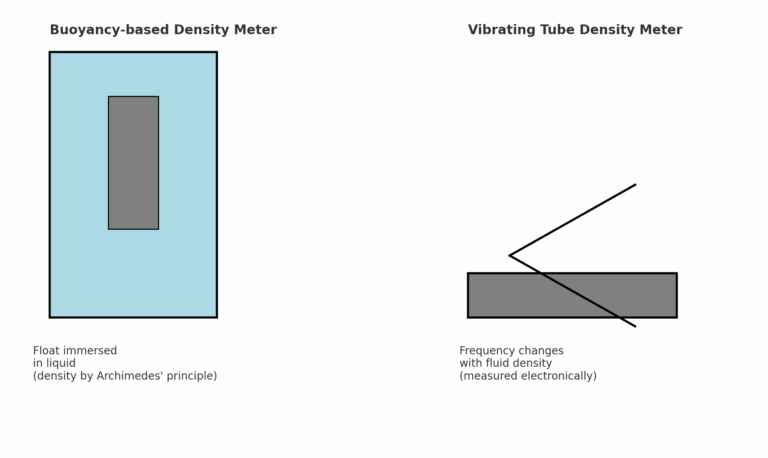

Buoyancy Principle (Hydrometer Type): According to Archimedes’ principle, the density of a liquid is determined by the buoyant force acting on a submerged float.

Vibrating Element Principle (Oscillating Tube Type): The resonance frequency of a vibrating tube changes with the density of the fluid inside. This variation is used to calculate the density.

Each type has distinct applications and performance characteristics, but both require periodic calibration to maintain measurement integrity.

3. Key Calibration Parameters The primary parameters assessed during density meter calibration include:

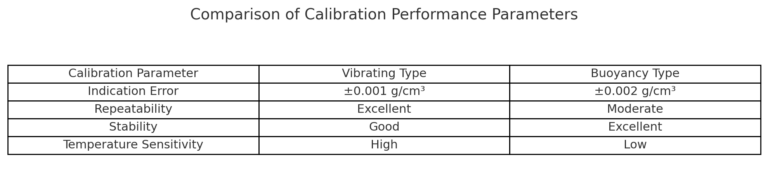

Indication Error (Accuracy): The deviation between the instrument reading and the reference value.

Repeatability: The consistency of results under the same measurement conditions.

Stability: The instrument’s ability to maintain its accuracy over time.

Calibration typically uses certified reference materials such as standard density liquids or blocks, with uncertainties at least 3 to 10 times lower than the instrument under test.

4. Applicable Calibration Standards Calibration procedures follow national metrology regulations. In China, the relevant standards include:

JJG 42-2001: Calibration Regulations for Glass Hydrometers

JJG 1058-2010: Calibration Regulations for Vibrating Type Liquid Density Meters

Internationally, commonly referenced standards include:

ISO 15212-1:2002: Oscillation-type Density Meters

ASTM D7777: Standard Test Method for Density, Relative Density by Oscillating U-Tube

5. Calibration Procedure Overview Standard calibration steps include:

Visual Inspection: Checking for physical damage, contamination, or wear.

Indication Error Test: Comparing meter readings to standard reference fluids.

Repeatability Test: Conducting multiple measurements under identical conditions.

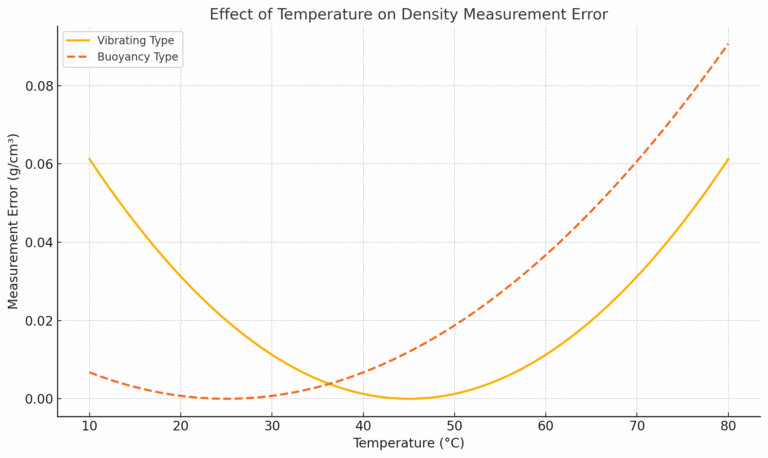

Temperature Influence Test (for vibrating type): Evaluating how temperature variations affect the density readings.

6. Common Issues and Mitigation Strategies Several challenges may arise during density meter calibration:

Temperature Effects: Drastic temperature shifts impact accuracy. Solution: use thermostatic baths or apply temperature compensation.

Viscosity of Samples: High viscosity may affect vibration response. Solution: perform viscosity correction or select suitable calibration standards.

Air Bubbles: Air entrapment in sample can distort buoyancy readings. Solution: degas samples before measurement.

Mechanical/Electronic Degradation: Sensor aging or circuit faults may degrade accuracy. Solution: conduct routine maintenance and timely part replacement.

7. Technological Advancements in Calibration Modern trends in density meter calibration include:

Automation: Reduces human error and improves efficiency.

Smart Diagnostics: Real-time status monitoring and predictive maintenance alerts.

In-situ Calibration: Enables on-site validation without disassembly.

New Reference Materials: Development of high-stability standards for improved precision.

8. Recommendations for Industrial Users To ensure reliable density measurements, organizations should:

Establish structured calibration schedules (e.g., semi-annual or annual depending on application).

Use certified calibration labs (ISO/IEC 17025 accreditation recommended).

Train personnel in proper handling and basic troubleshooting of density meters.

Keep detailed calibration records and traceability documentation.

Conclusion

Density meter calibration is a foundational quality control activity in modern industries. By adhering to recognized standards and embracing new technologies, enterprises can achieve high measurement confidence, ensure product quality, and optimize production processes.