1. Why Are Large Globe Valves Difficult to Operate?

For globe valves with diameters of DN200 and above, manual operation becomes significantly more difficult due to increased resistance. The average horizontal torque an adult can apply is approximately 60–90 kg, depending on physical strength.

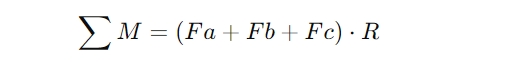

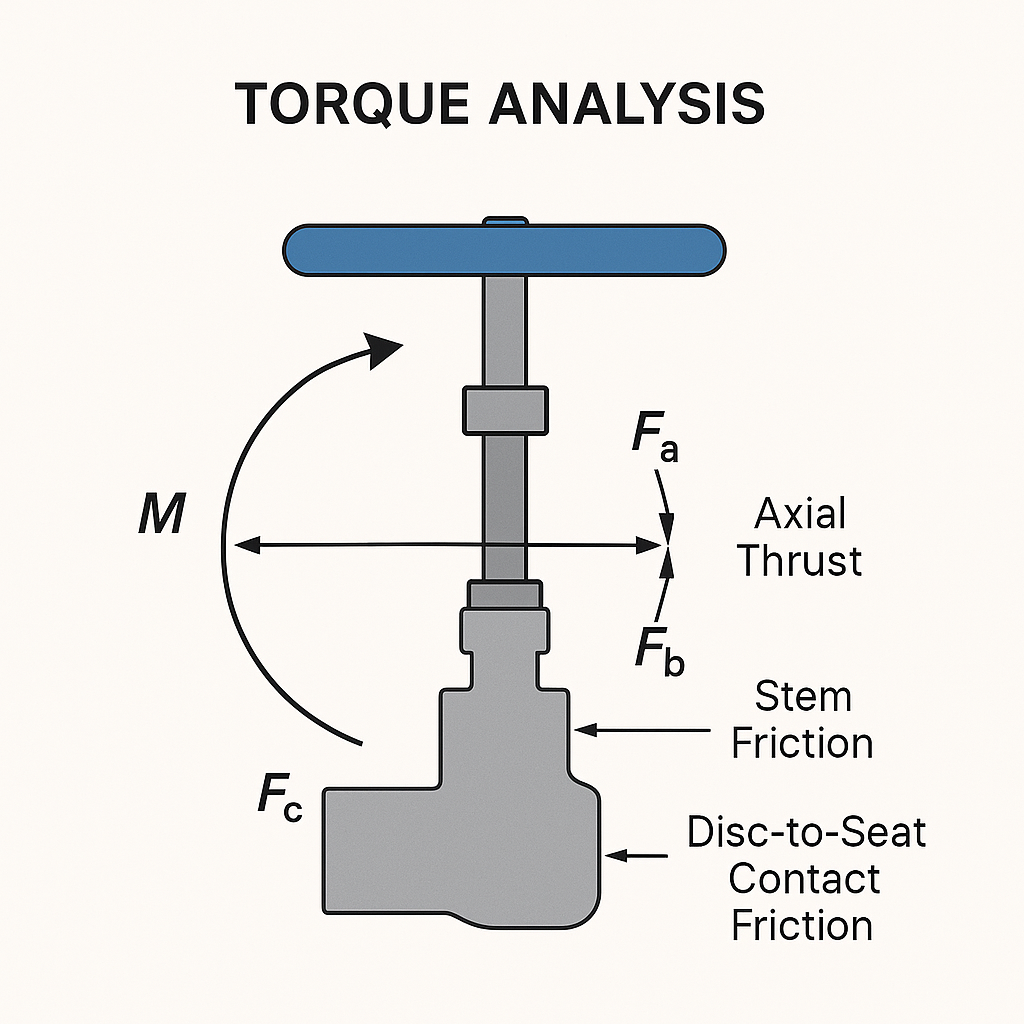

Standard globe valves are designed for flow direction from low to high. During valve closure, the operator must overcome the following forces:

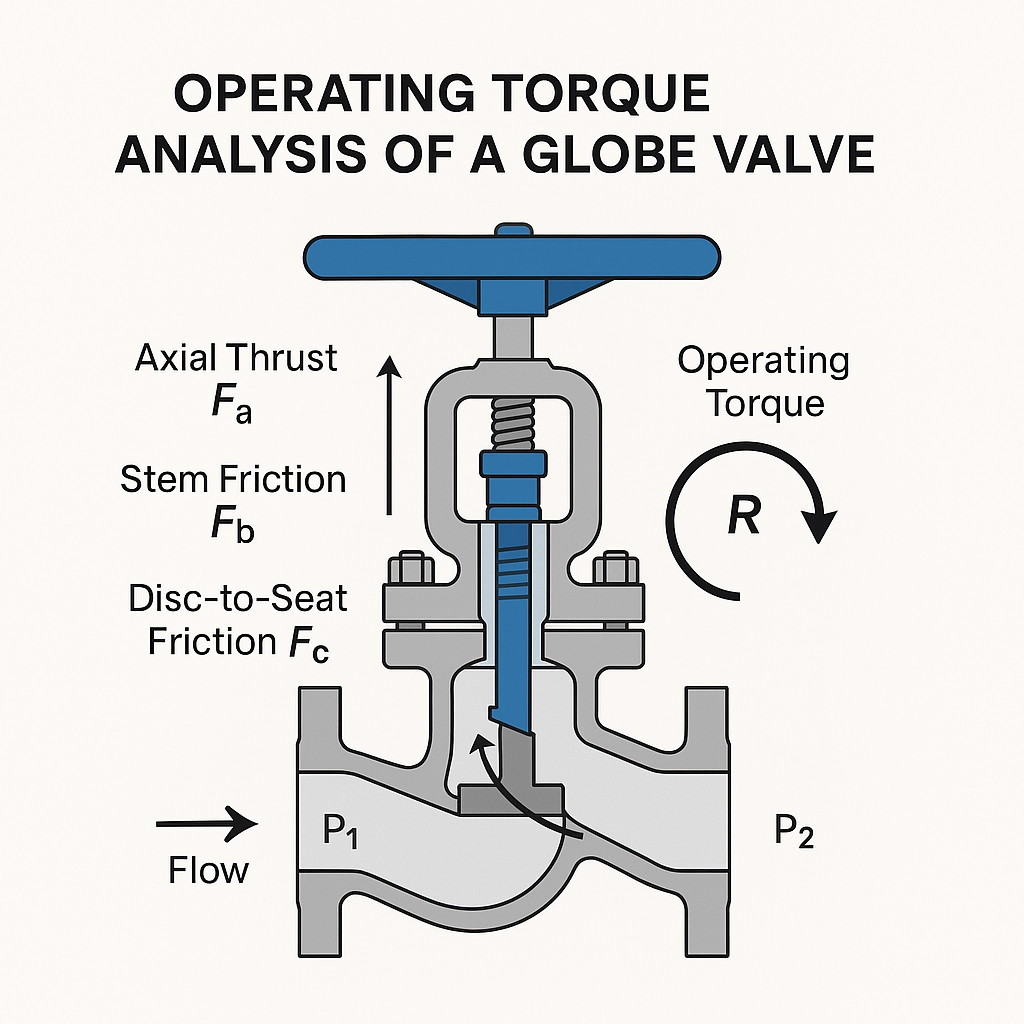

Axial Thrust (Fa): Generated by internal pressure acting on the valve disc

Stem Friction (Fb): Friction between valve stem and packing or guide

Disc-to-Seat Contact Friction (Fc): Caused by sealing surface resistance

The total torque required is:

📌 Illustration Suggestion: Torque vector diagram showing Fa, Fb, Fc forces and handwheel radius R.

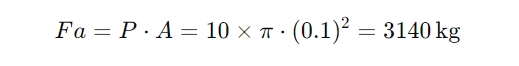

For example, a DN200 valve installed on a 10 bar steam line will experience an axial force of:

This exceeds the torque a person can comfortably apply, making manual closing extremely difficult.

Some factories attempt reverse installation to ease closing effort. However, this makes valve opening more difficult due to reverse axial load — not a recommended long-term solution.

2. Causes of Internal Leakage in Large Globe Valves

Large-diameter globe valves are commonly used at boiler outlets, steam headers, and main steam pipelines, where they are exposed to severe operating conditions:

2.1 High Pressure Drop and Steam Velocity

At boiler outlets, the large pressure difference creates high steam velocity, accelerating erosion of the sealing surface. Additionally, incomplete combustion may lead to wet steam, which promotes cavitation and flashing, degrading sealing integrity.

2.2 Corrosive and Crystallizing Deposits

Softening issues in boiler feedwater can cause acidic or alkaline components to precipitate near the sealing surface. Crystalline substances may also accumulate, preventing full closure and leading to internal leakage.

2.3 Fluctuating Flow in Steam Headers

Steam usage varies with production load, causing rapid changes in velocity. This fluctuation often leads to flashing and cavitation, damaging the seat and disc surface.

2.4 Valve Wear During Preheating

Pipelines must be preheated gradually to prevent thermal shock. During this stage, globe valves are partially opened, causing high-velocity flow through small openings, which increases local erosion and shortens valve life.

📌 Illustration Suggestion: Diagram of steam flow path and typical erosion zones on valve seat/disc.

3. Recommended Solutions

To address these challenges, the following engineering improvements are recommended:

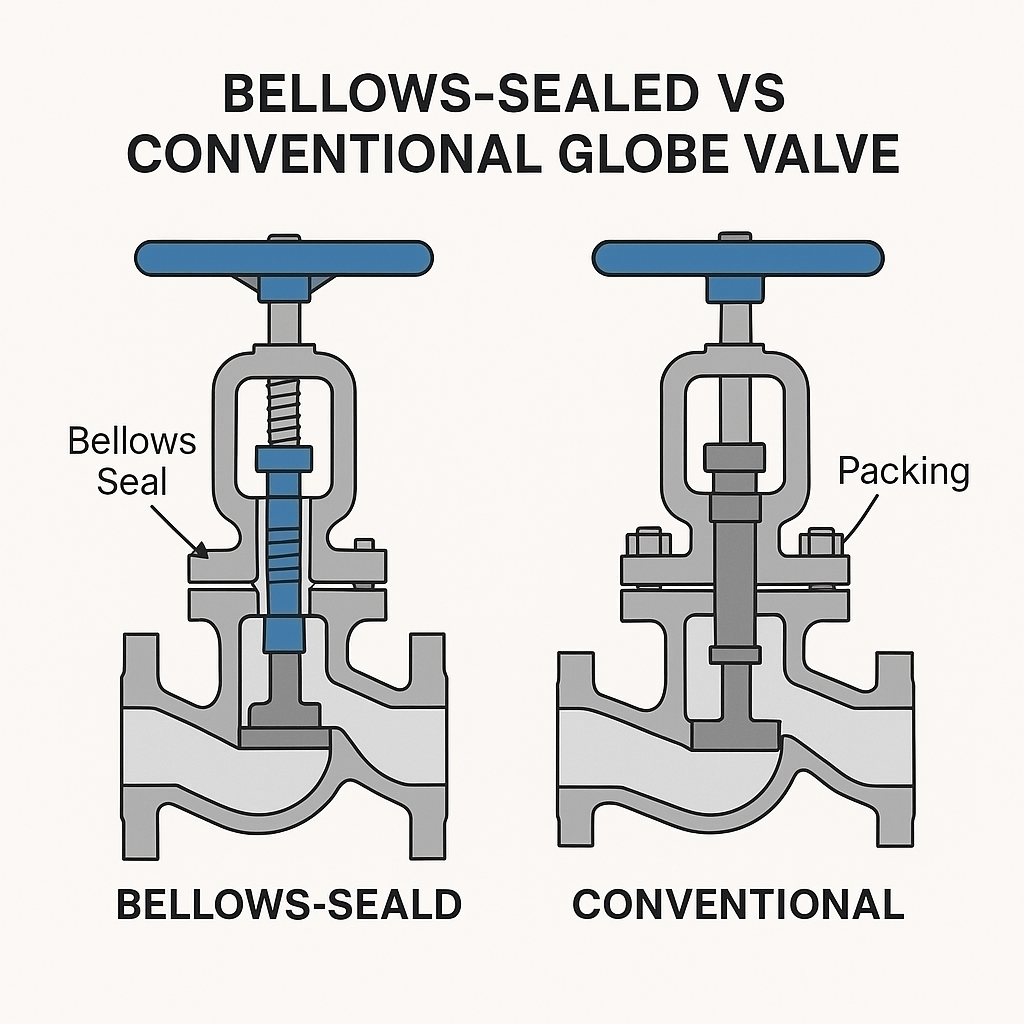

✅ 3.1 Use Bellows-Sealed Globe Valves

Bellows eliminate dynamic packing, reducing stem friction and operational torque. This makes valve opening and closing smoother.

✅ 3.2 Select Wear-Resistant Materials

Valve internals should use Stellite hard alloys or other corrosion-resistant materials to withstand erosion and cavitation.

✅ 3.3 Adopt Double-Disc Design

This reduces flow concentration through a single small opening, minimizing erosion at partial openings and improving sealing performance.

📌 Illustration Suggestion: Cutaway of bellows-sealed valve vs conventional globe valve, with annotated friction and sealing zones.

4. Conclusion

Large-diameter globe valves in high-pressure steam systems are prone to operational difficulty and internal leakage due to inherent force requirements and severe working conditions. By adopting bellows seals, wear-resistant materials, and optimized disc structures, long-term reliability and operational safety can be significantly improved.