Ball valves are widely used in industrial pipelines for fluid control. Among them, C-type, O-type, and V-type ball valves are three common types, each with distinct structural designs, sealing mechanisms, and application suitability. This article outlines their key differences to assist in proper selection and usage.

I. Structural Design and Working Principle

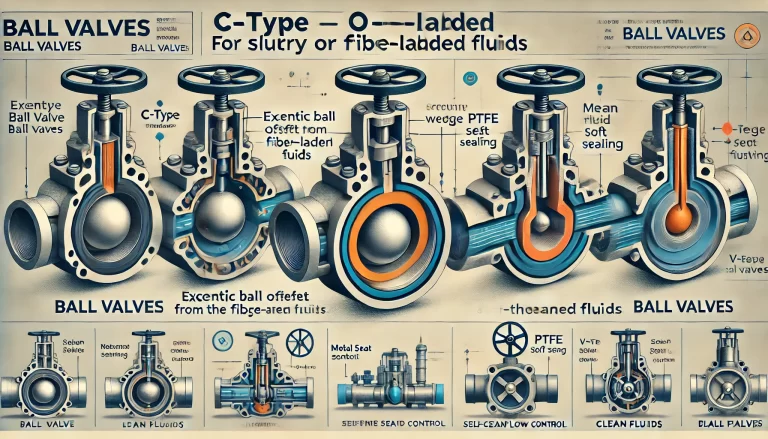

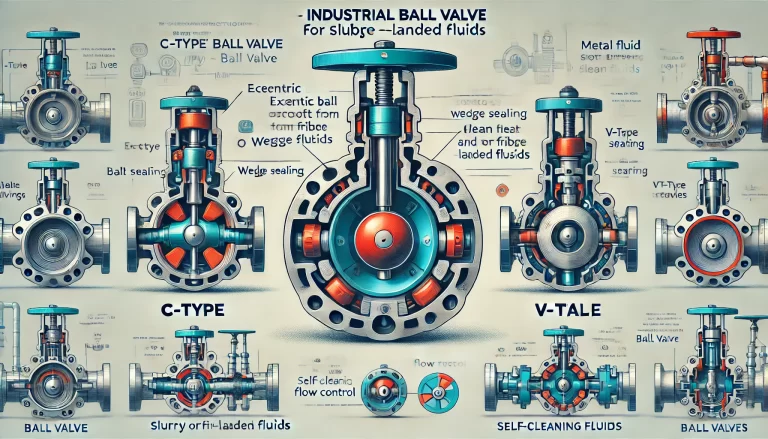

🔹 1. C-Type Ball Valve

The C-type ball valve features an eccentric structure where the ball is offset from the valve axis. It has a C-shaped flow passage and translates slightly during rotation, creating a wedge-sealing effect that improves tightness.

Sealing Mechanism: Utilizes either soft seals (e.g., PTFE) or metal-to-metal contact.

Typical Structure: The ball is supported by upper and lower shafts, ensuring stability and minimizing tilt.

Advantages:

Excellent sealing performance

High wear resistance — suitable for high-viscosity, fiber-laden, or slurry fluids

Low flow resistance, suitable for high flow applications

Disadvantages:

Potential seat wear when handling abrasive or particle-laden media

🔹 2. O-Type Ball Valve

The O-type ball valve uses a full-bore ball with a circular through-hole matching the pipe diameter. Rotation of the ball aligns or blocks the flow.

Sealing Mechanism: Elastic deformation of soft valve seat materials (e.g., PTFE, rubber) ensures a tight seal, even at low pressure.

Advantages:

Minimal pressure drop

Quick open/close operation

Reliable sealing for clean fluids

Disadvantages:

Requires higher torque to operate, especially under pressure

🔹 3. V-Type Ball Valve

The V-type ball valve has a V-notch in the ball, which varies the opening area as it rotates, enabling precise flow control.

Sealing Mechanism: Typically uses metal seats for high temperature/pressure resistance.

Advantages:

Superior throttling capability

Near equal-percentage flow characteristic

Self-cleaning action, ideal for media with fibers or solids

Disadvantages:

Higher cost and complexity

Sealing performance slightly lower than C-type and O-type

Requires periodic maintenance due to wear on the sealing edges

II. Application Scenarios

| Valve Type | Typical Applications |

|---|---|

| C-Type | For services demanding high sealing and abrasion resistance, such as oil & gas, chemical processing, wastewater treatment, and bulk fluid transfer. Ideal for frequent operation. |

| O-Type | Preferred in industries like food & beverage, pharmaceutical, and fine chemicals, where clean media and low-pressure tight sealing are essential. |

| V-Type | Best suited for flow control systems in chemical, petroleum, pulp & paper, and slurry applications, especially when media contain particles or fibers. |

III. Performance Comparison Table

| Feature | C-Type | O-Type | V-Type |

|---|---|---|---|

| Sealing Performance | ★★★★☆ | ★★★★☆ | ★★★☆☆ |

| Control Capability | ★★☆☆☆ | ★★☆☆☆ | ★★★★★ |

| Flow Resistance | Low | Very Low | Medium |

| Wear Resistance | High | Medium | High |

| Torque Requirement | Low | High | Medium |

| Maintenance Needs | Low | Low | Medium to High |

| Cost | Medium | Low to Medium | High |

IV. Conclusion

When selecting a ball valve, consider:

The nature of the fluid (clean, viscous, particle-laden)

Flow regulation needs (on/off vs. precise control)

Required sealing level and maintenance intervals

Each valve type offers strengths under specific conditions:

Choose C-Type for sealing and durability

Use O-Type where clean flow and low cost are key

Opt for V-Type when accurate control and media complexity are involved

For assistance with sizing or selection, contact our technical support team.