Coal silos generally fall into two categories: raw coal silos and pulverized coal silos. Each environment presents unique challenges for level measurement due to differences in dust concentration, humidity, and material properties. This article analyzes the characteristics of each condition and recommends suitable level detection solutions accordingly.

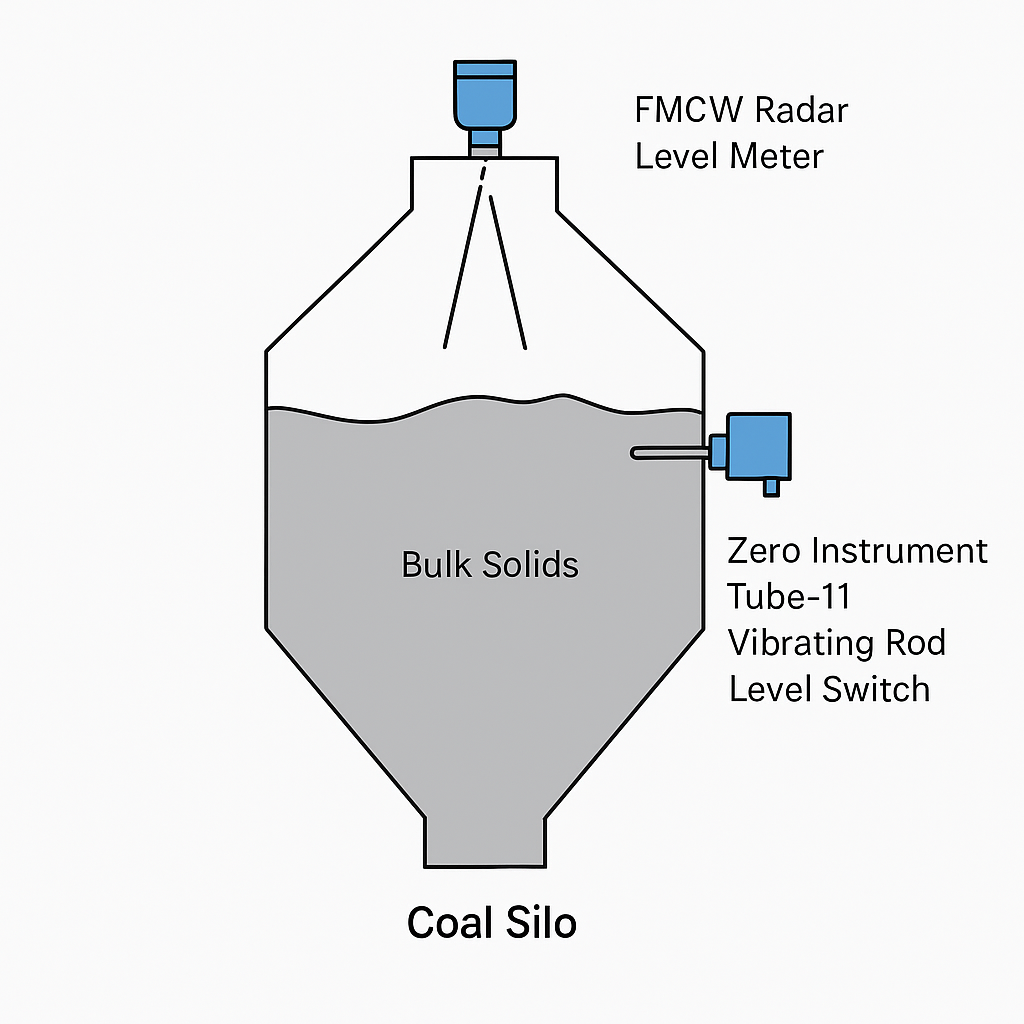

1. Level Switch Selection for Raw Coal Silos

Raw coal silos typically have lower dust concentrations, making them relatively easy to manage with conventional measurement instruments.

Recommended Solutions:

Continuous Level Measurement:

Ultrasonic Level Meters or Pulse Radar Level Meters are commonly used for non-contact, continuous measurement.

Point Level Detection (for cost-saving needs):

Level Switches can be deployed for high or low-level alarms where high precision is not required.

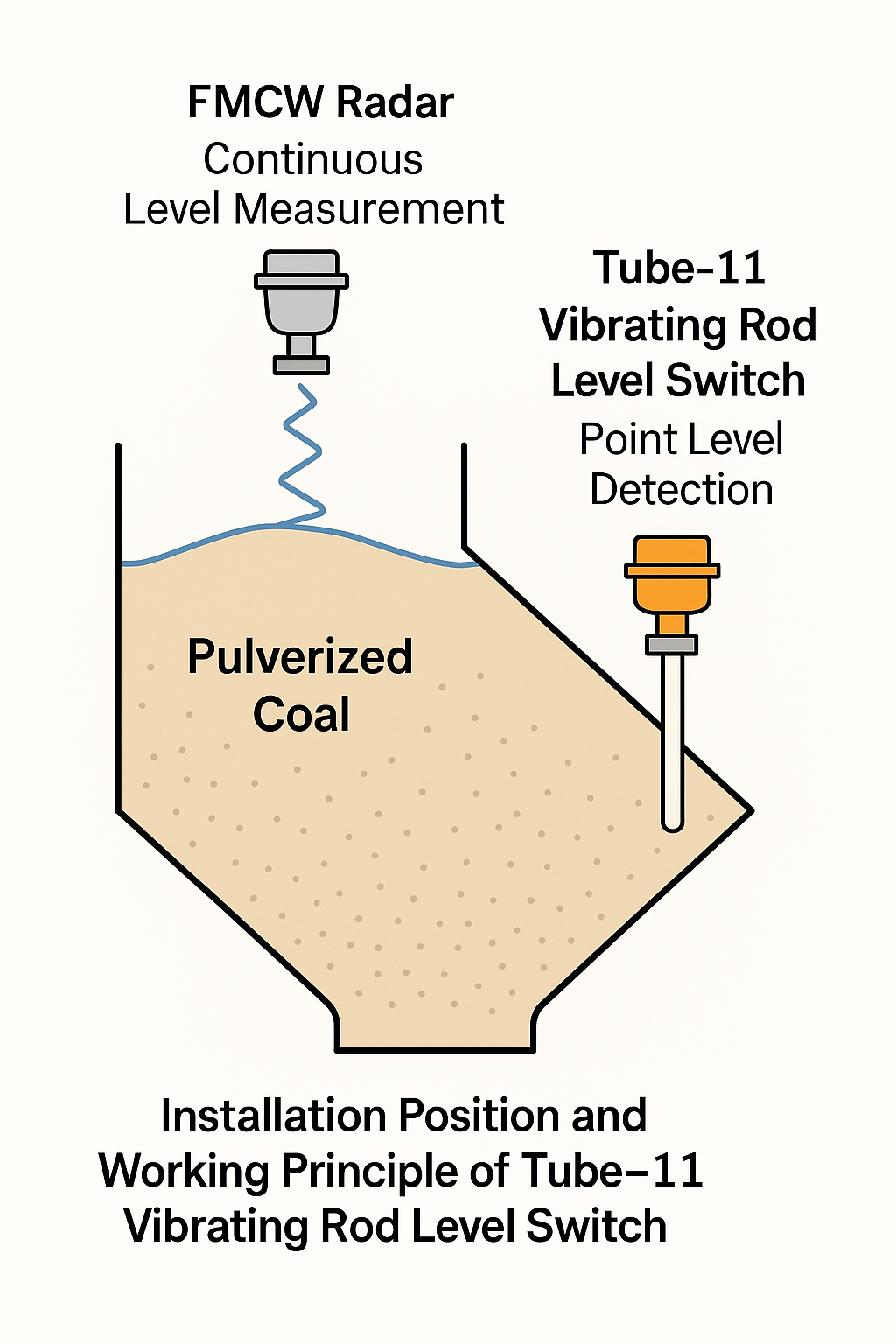

2. Level Switch Selection for Pulverized Coal Silos

Pulverized coal silos are high-dust environments that pose significant challenges for traditional ultrasonic or pulse radar level meters.

Challenges:

High dust concentration interferes with signal transmission.

Material buildup and condensation, especially in humid climates, affect contact sensors.

Recommended Solutions:

FMCW (Frequency Modulated Continuous Wave) Radar Level Meters:

These have strong penetration through dust and are well-suited for large measuring ranges in powdery environments.Contact-type Level Switches (for reliable point detection):

In humid regions (especially southern climates), raw coal can become sticky. This leads to material buildup on traditional point-level sensors, reducing accuracy and reliability.

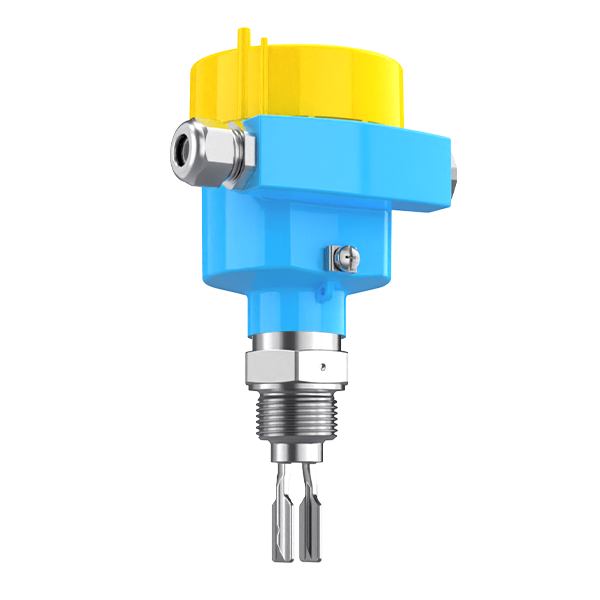

3. Featured Product: Zero Instrument Tube-11 Vibrating Rod Level Switch

To address sticking and false alarms, Zero Instrument developed the Tube-11 Vibrating Rod Level Switch, which features a patented double-tube design.

Key Advantages:

Anti-Buildup Design:

The inner and outer tube configuration enhances resistance to material adhesion and sticking, ensuring long-term reliability in sticky or cohesive media.High Sensitivity:

Capable of detecting bulk solids with a minimum density of 0.02 g/cm³.Explosion Protection:

Flameproof: Ex db IIC T1…T6 Gb

Dust Explosion-Proof: Ex tb IIIC T80℃…T440°C Db

Intrinsic Safety: Ex ia IIC T1…T6 Ga, Ex ia IIIC T200100℃…T200450℃ Da

Ingress Protection:

Rated IP66/IP67 for harsh industrial environments.Proven Performance:

The Tube-11 has received consistent praise from users since its launch, and is widely regarded as a competitive alternative to imported brands.

4. Summary Table of Level Measurement Recommendations

| Silo Type | Dust Level | Recommended Instrument | Key Benefits |

|---|---|---|---|

| Raw Coal Silo | Low | Ultrasonic / Pulse Radar / Switch | Cost-effective, easy to deploy |

| Pulverized Coal Silo | High | FMCW Radar / Tube-11 Vibrating Rod | Dust resistance, anti-sticking, robust |