In industrial process automation, control valves are among the most important final control elements. Valve positioners—especially smart electro-pneumatic types—play a vital role in improving control accuracy, response speed, and system efficiency.

Smart valve positioners can be classified by their I/P converter mechanisms into two main types: nozzle-flapper and piezoelectric valve. Leading global manufacturers use different structures. For instance:

Piezoelectric I/P: Siemens SIPART PS2, Metso ND9000

Nozzle-Flapper I/P: Emerson Fisher DVC6200, SAMSON 3730-3, Azbil AVP300

These two types differ significantly in working principle, structural design, energy efficiency, control performance, and applicable scenarios. This article presents a detailed comparison.

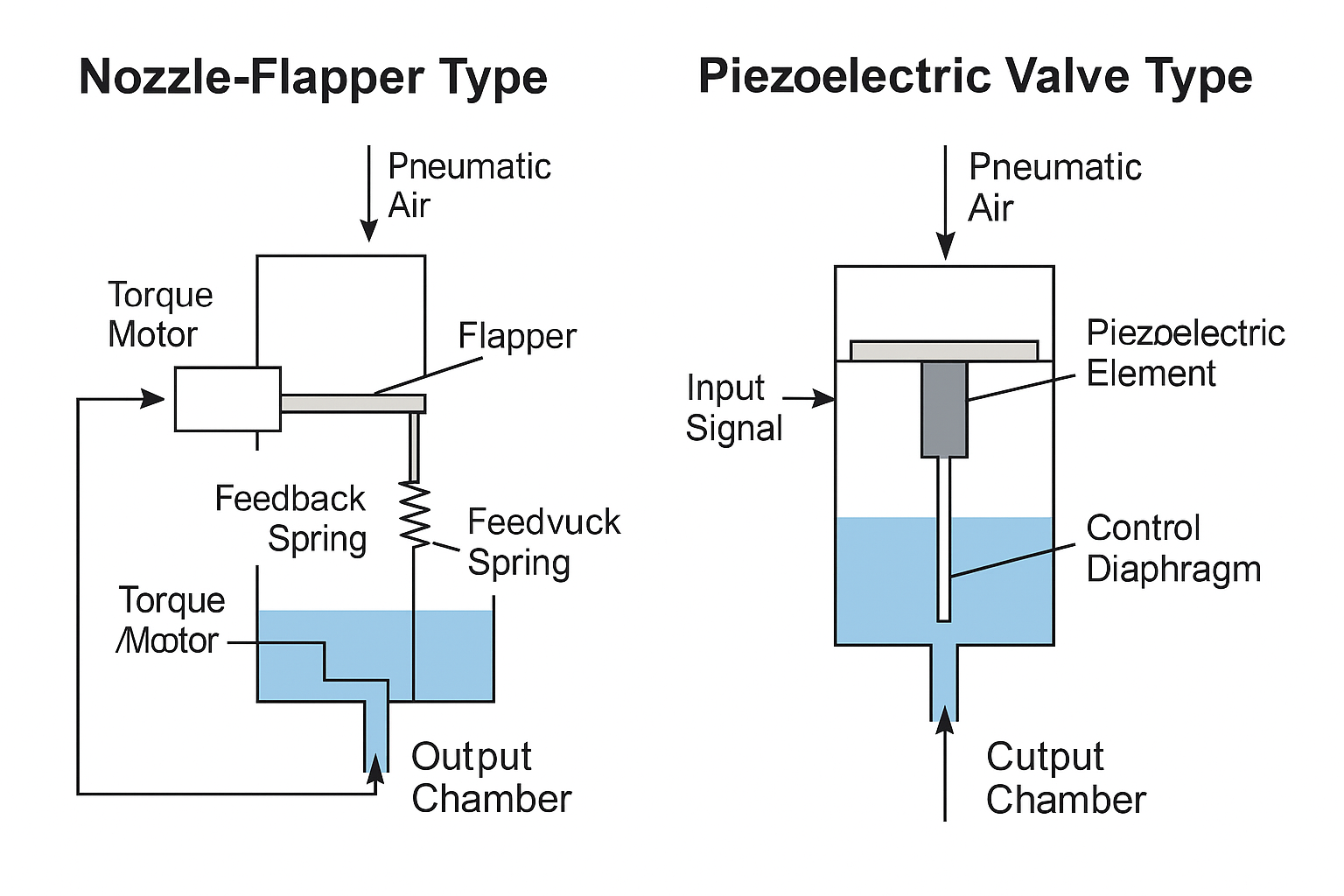

1. Working Principle

🔹 Nozzle-Flapper Type

This system operates on a force balance principle. It regulates backpressure by varying the distance between a nozzle and a flapper, which in turn controls the valve position. Key components include:

Fixed and variable orifices

Pneumatic chambers

A feedback spring

As the gap between the nozzle and flapper changes, the pressure on the diaphragm shifts, driving the actuator accordingly.

🔹 Piezoelectric Valve Type

This system uses the piezoelectric effect. When an electric signal is applied, a piezoelectric element deforms, adjusting airflow resistance and modulating output pressure.

Modern piezoelectric valves—such as the P9 and P20 series by Hoerbiger—are widely used in smart positioners.

A power-amplified piezoelectric valve integrates the piezoelectric controller with a pneumatic amplifier, enabling accurate control of valve actuators.

2. Air Consumption and Energy Efficiency

🔹 Nozzle-Flapper

Continuously consumes air, even at steady state.

Typically higher energy consumption.

Air loss occurs through the nozzle regardless of control activity.

🔹 Piezoelectric Valve

Consumes air only when correcting a position deviation.

In standby, air usage is nearly zero.

Siemens SIPART PS2 consumes only 1/10 to 1/20 the air compared to conventional designs.

3. Accuracy and Response Speed

🔹 Nozzle-Flapper

Mechanical contact may cause wear, vibration sensitivity, and output instability.

Precision declines over time due to mechanical drift and environmental factors.

🔹 Piezoelectric Valve

Compact, frictionless structure.

Immune to vibration and thermal variation.

Faster response and higher accuracy due to microprocessor-based control.

4. Control Algorithms

🔹 Nozzle-Flapper

Typically uses traditional PID algorithms.

Fast dynamic response but may suffer from nonlinearity and hysteresis.

🔹 Piezoelectric Valve

Supports advanced adaptive algorithms (e.g., single-neuron adaptive PSD control).

Better suited for complex, time-varying, or nonlinear systems.

5. Application Scenarios

🔹 Nozzle-Flapper

Suitable for cost-sensitive, low-precision applications.

Performs well in poor air quality environments due to rugged mechanical design.

Ideal for general-purpose control systems.

🔹 Piezoelectric Valve

Best suited for precision control, high-speed response, and low-energy applications.

Widely used in petrochemical, power generation, and high-end automation.

Requires clean and stable air supply.

Conclusion

Both nozzle-flapper and piezoelectric smart positioners have their own strengths and weaknesses:

| Feature | Nozzle-Flapper Type | Piezoelectric Valve Type |

|---|---|---|

| Structure | Mechanical, simple | Compact, advanced |

| Air Consumption | Continuous | On-demand |

| Response Speed | Moderate | Fast |

| Accuracy | Moderate | High |

| Cost | Lower | Higher |

| Suitability | General environments | Demanding precision applications |

Selection should be based on application needs, including control precision, energy consumption, cost, and air quality conditions. As industrial automation moves toward smarter and more energy-efficient systems, piezoelectric valve positioners are increasingly favored in modern facilities.