In today’s industrial environments, system uptime and reliability are crucial. Whether you’re running a data center, a chemical processing plant, or an automated manufacturing line, even a brief power failure can lead to costly downtime, product losses, or safety hazards. That’s where power redundancy modules come into play.

This article explains what a power redundancy module is, its core functions, and why it is a vital component in any mission-critical system.

1. What Is a Power Redundancy Module?

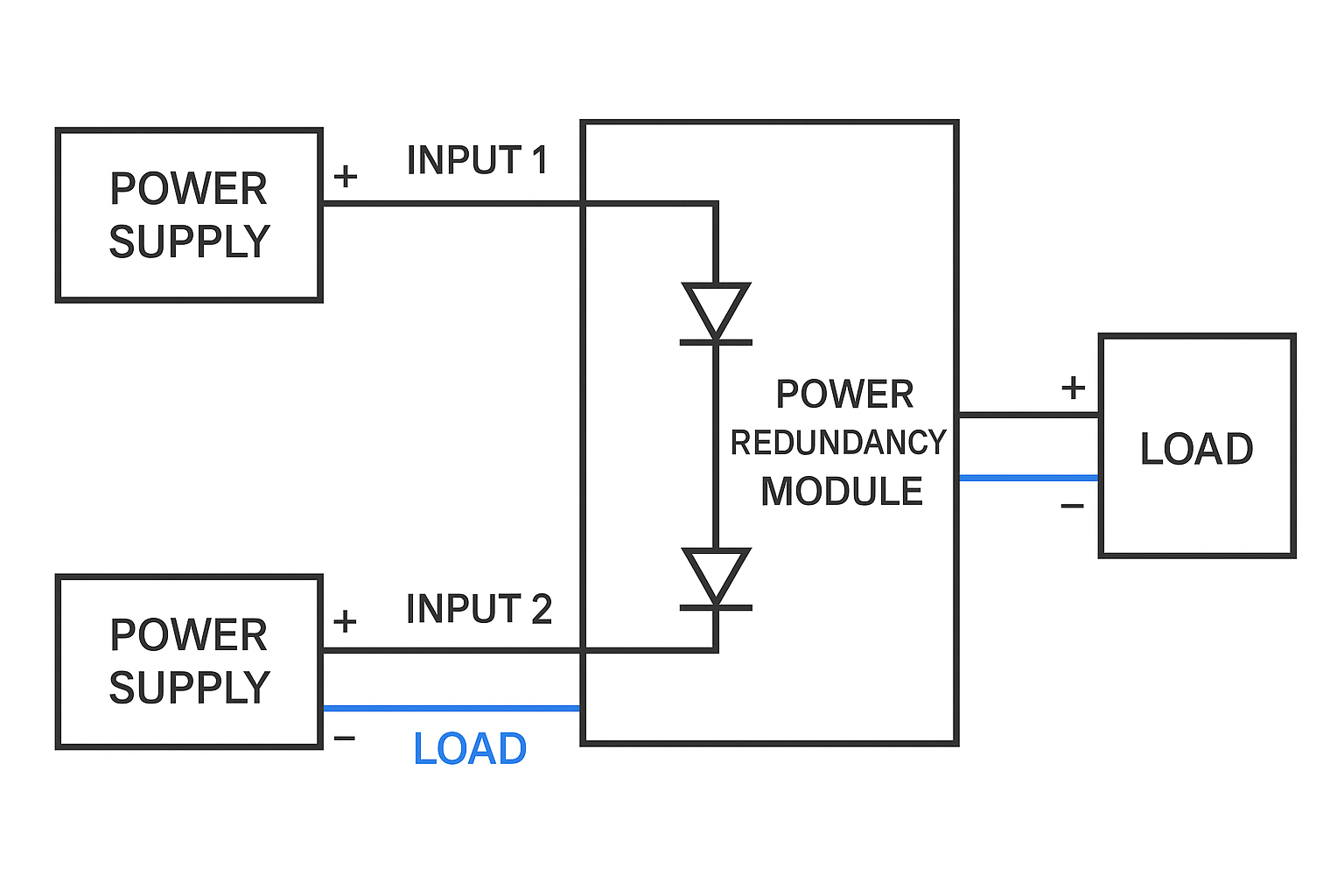

A power redundancy module is a device used in conjunction with power supplies to ensure uninterrupted power delivery. It allows two or more power sources to be connected in parallel and automatically switches between them if one fails.

The module prevents reverse current flow between power supplies and ensures load sharing, enabling high system reliability without manual intervention.

2. Key Functions and Benefits

✅ Increased System Reliability

Redundancy modules allow systems to continue operating even if one power supply fails. This is particularly critical in applications like process automation, security systems, or emergency response units.

✅ Fault Tolerance

A redundant power setup prevents a single point of failure. When one power source is down due to maintenance or unexpected faults, the other supply takes over seamlessly.

✅ Load Sharing

Many modules allow for current balancing between two power supplies. This not only extends the lifespan of the supplies but also improves system efficiency.

✅ Simplified Maintenance

With redundant systems, one power supply can be replaced or serviced without shutting down the entire system, greatly simplifying maintenance tasks.

✅ Protection Against Overload

Some redundancy modules provide overcurrent protection, ensuring that any overload on one power source doesn’t cascade through the rest of the system.

3. Where Are Redundancy Modules Used?

Power redundancy modules are essential in various industrial applications, such as:

PLC and DCS control cabinets

SCADA and industrial computer systems

Oil & gas field instrumentation

Power plants and utility substations

Mission-critical safety systems

4. Choosing the Right Redundancy Module

When selecting a power redundancy module, consider the following:

Rated input and output current (must match or exceed your power supplies)

Voltage range compatibility

Mounting type (DIN-rail is common)

Isolation design (diode-based vs. MOSFET-based)

Diagnostic features (LED indicators, relay alarms, etc.)

5. Conclusion

If your process can’t afford interruptions, implementing power redundancy is not optional—it’s essential. A quality power redundancy module ensures that your automation or monitoring system stays live even during a power supply failure. This small investment can safeguard major infrastructure and reduce the risk of costly downtime.

For industries seeking maximum uptime and safety, Dalian Zero Instrument Technology Co., LTD offers reliable, industry-grade solutions including redundancy power modules, transmitters, and full automation systems.