1. Introduction

Acrylamide (chemical formula: C₃H₅NO) is a white, odorless crystalline solid commonly used in the production of polymers, adhesives, flocculants, and in laboratory research. Despite its low volatility under standard conditions, acrylamide is highly toxic, and prolonged exposure poses serious health risks, including neurotoxicity and potential carcinogenicity.

This article explores whether workplaces that handle acrylamide should install toxic gas detection systems, based on risk assessment, regulatory standards, and practical safety considerations.

2. Key Toxicological and Physical Properties

| Property | Description |

|---|---|

| CAS Number | 79-06-1 |

| Appearance | White crystalline solid |

| Boiling Point | Decomposes before boiling |

| Vapor Pressure | Low at room temperature |

| Toxicity | Neurotoxic, carcinogenic (Group 2A by IARC) |

| Occupational Exposure Limit (China GBZ 2.1-2019) | TWA: 0.03 mg/m³ |

Although acrylamide is not highly volatile, under certain conditions such as heating, misting, or poor ventilation, it can vaporize or generate aerosols and toxic decomposition products, leading to airborne hazards.

3. Situations Requiring Toxic Gas Detection

While acrylamide itself is a solid at room temperature, the need for toxic gas detectors depends on several specific risk factors:

✔ Recommended Situations for Gas Detector Installation:

| Situation | Recommendation | Reason |

|---|---|---|

| Heated processes (e.g., drying, melting, polymerization) | Yes | Elevated temperatures may lead to vaporization or release of decomposition gases. |

| Confined spaces or poor ventilation | Yes | Limited airflow increases risk of accumulation of airborne toxins. |

| Bulk storage and large-scale handling | Yes | Greater volume increases potential hazard in the event of a spill or leak. |

| Use with other reactive chemicals | Yes | Reactions with acids, oxidizers, or bases may release toxic gases such as ammonia or acrylonitrile. |

⚠ Situations Where Detectors May Be Optional (With Caution):

| Situation | Recommendation | Condition |

|---|---|---|

| Small-scale, cold, well-ventilated operations | Not required, but good ventilation essential | Exposure risk is minimal under proper handling and containment. |

4. Applicable Regulations and Standards

🏛 Chinese Standards (as reference):

GBZ 2.1-2019: Limits acrylamide occupational exposure to 0.03 mg/m³ (TWA).

GB 50493-2019 (Code for Design of Toxic Gas Alarm Systems): Requires gas detection in workplaces handling toxic chemicals with inhalation risk.

GB 50160-2008 (Code for Design of Chemical Plant Fire Protection): Suggests monitoring systems for environments with high chemical risk.

🌐 International Considerations:

OSHA (U.S.): Acrylamide exposure limit is 0.03 mg/m³ (8-hour TWA).

NIOSH/ACGIH: Recommend stringent exposure limits and appropriate detection for airborne contaminants.

In both domestic and international standards, risk-based assessment determines whether gas detection is mandatory—but it is strongly recommended in hazardous handling scenarios.

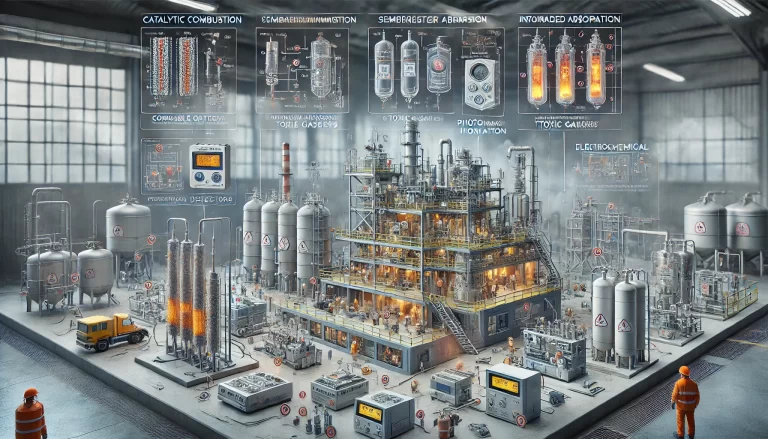

5. Types of Gas Detectors to Consider

Acrylamide itself is difficult to detect directly in vapor form due to its low volatility. However, detectors can be selected based on possible by-products or associated risks:

| Detector Type | Target Gas | Use Case |

|---|---|---|

| PID (Photoionization Detector) | VOCs including acrylamide vapor (indirectly) | General air monitoring for toxic vapors. |

| Ammonia Gas Detector | NH₃ | If acrylamide is used in reactions producing or degrading into ammonia. |

| Acrylonitrile Detector | C₃H₃N | For acrylamide-derived by-products in thermal degradation. |

| Particulate Monitors | Dust/Aerosol particles | Useful if acrylamide is handled as powder or misted. |

6. Conclusion and Recommendation

Toxic gas detectors are highly recommended in environments where acrylamide is heated, processed in large volumes, or used in confined or poorly ventilated areas.

Even though acrylamide has low volatility, the potential for inhalation exposure through vapor, mist, or by-products makes continuous air quality monitoring a wise precaution. Combining local exhaust ventilation (LEV), personal protective equipment (PPE), and toxic gas alarms can significantly reduce health risks and ensure compliance with occupational safety standards.

7. Additional Safety Measures

Air sampling and occupational exposure testing should be performed periodically.

Workers should use respirators if airborne acrylamide is suspected.

Install emergency ventilation or extraction fans in enclosed areas.

Ensure spill response procedures and PPE training are in place.