1. What is a Float Level Switch?

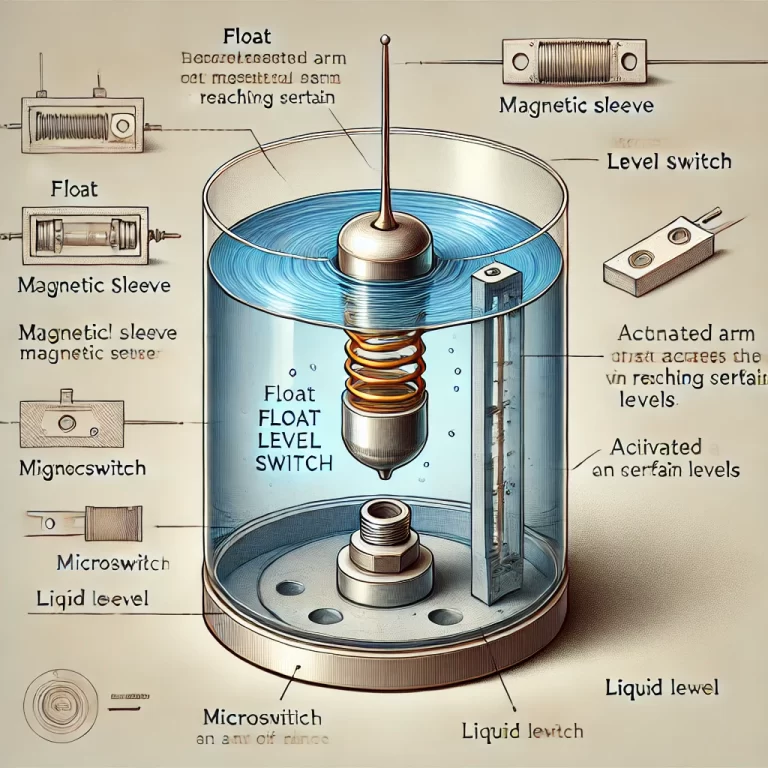

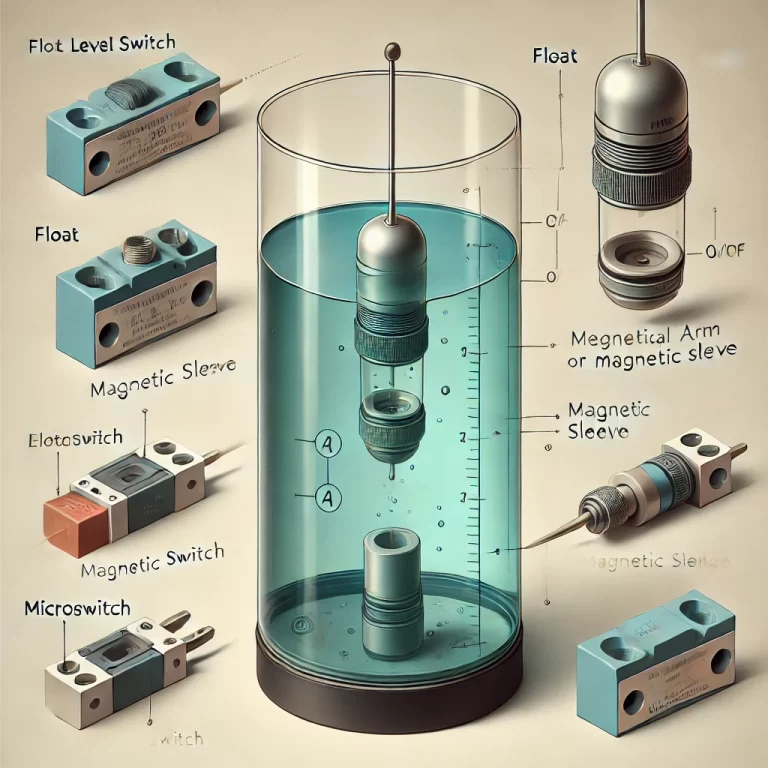

A float level switch is a device that utilizes the principle of liquid buoyancy to detect liquid level changes, trigger alarms, or control pump operations. When the liquid level rises or falls to a certain point, the float moves accordingly, activating an internal microswitch to output an on/off signal.

In simple terms:

Movement of the float → Activation of the switch → Liquid level control achieved

2. Working Principle of Float Level Switches

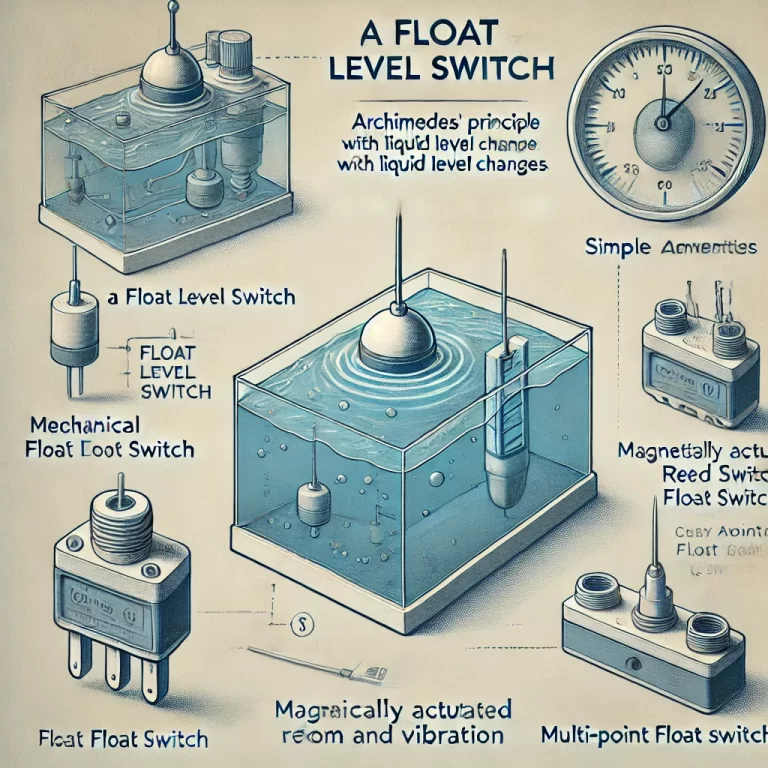

Float level switches operate based on Archimedes’ principle of buoyancy. As the liquid level changes, the float moves vertically. This movement is mechanically linked to a magnetic sleeve. When the magnetic sleeve enters a designated magnetic field area, magnetic coupling triggers the corresponding magnet to actuate the switch, resulting in a change in the contact state.

When the liquid level falls, the magnet is released by spring force, and the switch contacts return to their original state, thereby enabling control functions such as liquid level monitoring, alarms, and fault interlocks.

3. Common Types of Float Level Switches and Their Applications

Mechanical Float Switches: Simple structure, low cost, high reliability. Ideal for sewage treatment plants and standard water tanks.

Magnetically Actuated Reed Switch Float Switches: No mechanical wear, long service life, excellent sealing. Suitable for chemical liquids and oil storage tanks.

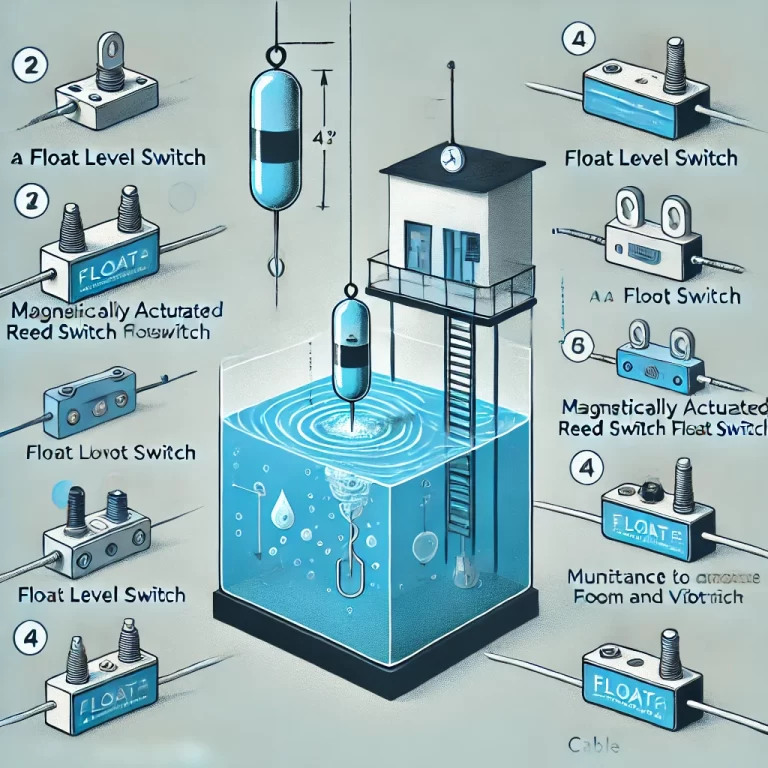

Multi-point Float Switches: One rod can accommodate multiple detection points for multi-stage control; commonly used in large storage tanks.

Cable Float Switches: Highly flexible installation, can float freely with the liquid level. Suitable for deep well water control and wastewater treatment facilities.

4. Main Advantages of Float Level Switches

Simple design, low manufacturing and maintenance costs

Easy installation and maintenance

Suitable for high temperature, high pressure, and corrosive liquid environments

Applicable to a wide range of liquids (water, oil, acids, alkaline solutions)

Unaffected by foam, vapor, or vibration, ensuring stable and reliable operation

5. Limitations of Float Level Switches

Not suitable for environments with strong turbulence or severe agitation (may cause false triggering)

Requires special design considerations for extremely low specific gravity liquids (e.g., lightweight oils)

Performance may degrade due to contamination or buildup on the float (regular cleaning recommended)

6. Typical Applications of Float Level Switches

Liquid level alarms in municipal water treatment plants

Water level control in agricultural irrigation systems

Water level monitoring in industrial cooling towers

Fuel tank level alarms on marine vessels

Liquid level control in chemical storage tanks

Automatic start/stop control for household water pumps

7. Key Considerations for Selecting a Float Level Switch

When choosing the appropriate float level switch, consider the following factors:

Liquid Type: Clean water, wastewater, oils, corrosive chemicals?

Temperature and Pressure Requirements: Does the application require high-temperature or high-pressure resistance?

Switch Type: Normally Open (NO), Normally Closed (NC), or switchable configuration?

Number of Detection Points: Single-point or multi-point control?

Mounting Method: Top-mounted, side-mounted, or suspended installation?

Certification Requirements: Such as explosion-proof certification (ATEX) or sanitary certification (FDA) for specific industries.