1. Introduction

Compressed air is widely used across industrial sectors, including manufacturing, petrochemicals, mining, and utilities. It serves as a critical energy medium for pneumatic tools, process controls, material handling, and other applications. Despite its importance, understanding the fire hazard classification of compressed air is essential for safe facility design, fire protection planning, and compliance with safety standards.

This article provides a detailed explanation of the fire hazard classification of compressed air, based on prevailing fire codes and safety guidelines.

2. Understanding Fire Hazard Classifications

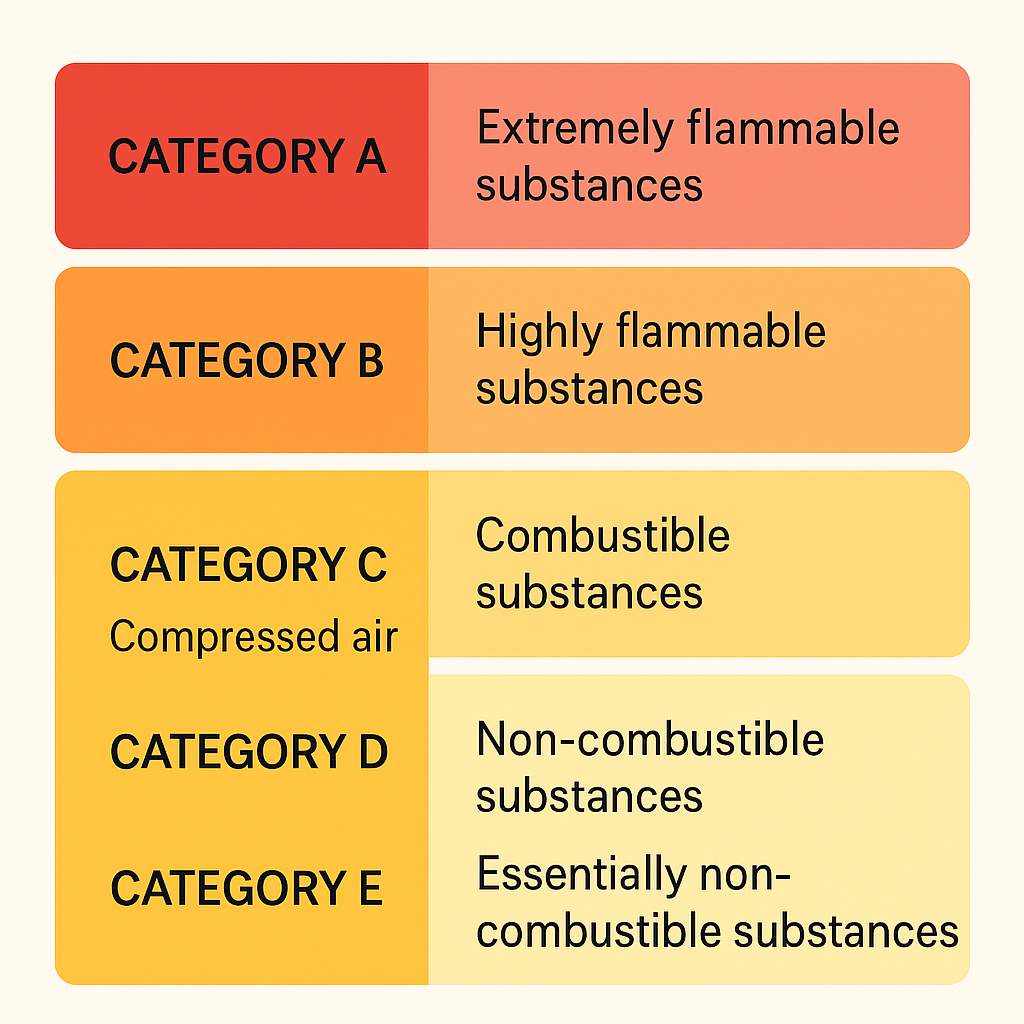

In industrial and building fire safety codes, materials are classified into fire hazard categories according to their flammability, explosiveness, and potential to contribute to a fire event. In China, the standard reference is the “Code for Fire Protection Design of Buildings” (GB50016), which divides substances into five categories:

Category A : Extremely flammable substances.

Category B : Highly flammable substances.

Category C : Combustible substances that are difficult to ignite under normal conditions but can intensify fire once ignited.

Category D : Non-combustible substances under normal temperature and pressure but may produce harmful gases or high temperatures when heated.

Category E : Essentially non-combustible substances with minimal fire hazard.

3. Fire Hazard Category of Compressed Air

Compressed air typically consists of:

Nitrogen (~78%)

Oxygen (~21%)

Small amounts of other inert gases

Key characteristics of compressed air:

It is not flammable under normal operating conditions.

However, due to its oxygen content, it can intensify combustion if a fire starts in the surrounding environment.

Compressed air itself does not ignite or explode, but leaks in oxygen-rich environments can significantly enhance the severity of fires.

Therefore, based on fire safety codes:

Compressed air is classified as a Category C fire hazard material.

This classification is consistent with how compressed gases and liquefied gases (excluding flammable gases) are categorized in fire protection regulations.

4. Safety Implications for Facility Design

While compressed air is relatively safe compared to flammable gases like hydrogen or propane, specific precautions are still necessary:

Piping and Storage: Ensure that compressed air piping systems are built to withstand the designed pressure without leaks, as high-pressure oxygen-enriched leaks can be hazardous.

Ventilation: Proper ventilation should be maintained in compressor rooms and confined spaces to prevent localized oxygen enrichment.

Fire Detection Systems: Although compressed air itself is not a fire source, fire detection and suppression systems should be in place, especially in areas with potential ignition sources.

Maintenance Practices: Regular inspection of compressors, receivers, and pipelines minimizes the risk of mechanical failure that could lead to accidents.

Training: Personnel must be trained to handle compressed air systems safely, particularly when operating in areas where sparks or open flames are present.

5. Special Cases: Oxygen-Enriched Compressed Air

In specialized applications (such as medical facilities, hyperbaric chambers, or welding operations), compressed air may be enriched with oxygen. If the oxygen concentration exceeds 23.5%, the fire hazard risk increases substantially. In such cases:

The environment is treated as high-risk.

Materials that are normally considered non-combustible may ignite easily.

Enhanced fire protection measures must be implemented.

6. Conclusion

Compressed air is classified under Category C fire hazard materials, meaning it poses a moderate fire risk primarily due to its oxygen content and its potential to intensify fires. While it is generally safe under controlled conditions, proper system design, maintenance, and emergency preparedness are vital to minimize associated risks.

By understanding the fire hazard properties of compressed air, industries can ensure safer operations, improve fire protection strategies, and comply with regulatory requirements.