Maintaining the cleanliness and hygiene of ultrasonic level sensor probes is essential to ensure accurate measurement and prolong the device’s service life, especially in food production environments. This guide provides detailed, standardized procedures for cleaning, disinfecting, and maintaining food-grade ultrasonic level probes.

1. Preparations Before Cleaning

1.1 Power Disconnection

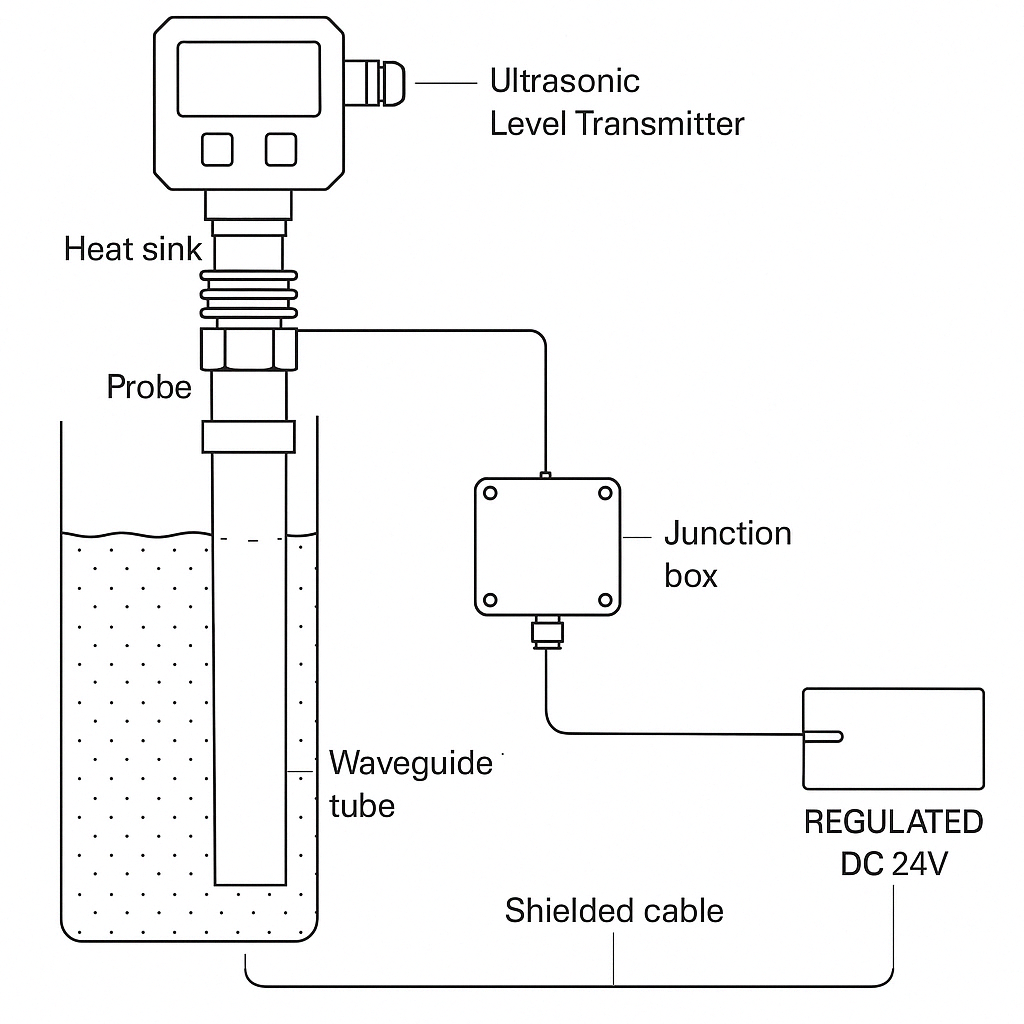

Disconnect the power supply to the probe and the associated level meter before cleaning.

This prevents electric shock, short circuits, and potential equipment damage.

1.2 Tools and Materials

Cleaning Tools: Use soft, non-woven fabrics, cotton cloths, or sponges.

Prohibited Tools: Avoid abrasive tools such as steel wool or hard-bristle brushes.

Cleaning Agents: Choose food-grade, mild neutral solutions (e.g., clean water or diluted dishwashing liquid).

Prohibited Agents: Do not use alcohol, strong acidic or alkaline solutions.

2. Cleaning Procedures

2.1 Surface Dirt Removal

Gently wipe the probe surface using a damp soft cloth to remove residues such as food debris and grease.

Always wipe parallel to the probe surface to minimize scratching.

For stubborn contaminants, spray a small amount of neutral cleaner onto the probe and let it sit for 1–2 minutes before wiping. Do not scrape forcefully.

2.2 Deep Cleaning (Special Situations)

Spray Cleaning: Use a spray bottle to evenly distribute cleaning solution onto hard-to-reach gaps. Follow with a soft cloth to wipe clean.

Magnetic Cleaning: In narrow areas, use magnetic cleaning tools to attract and remove dirt, minimizing physical damage to the probe.

2.3 Rinsing and Drying

Wipe off residual cleaning agent with a clean, water-dampened non-woven cloth to ensure no chemical residues remain.

Dry the probe naturally or use a lint-free soft cloth to absorb moisture.

Prohibited Methods: Avoid using high-temperature baking or direct strong air jets, as these can cause material deformation or seal failure.

3. Disinfection and Maintenance

3.1 Food-Grade Disinfection

Wipe the surface with food-grade quaternary ammonium compound (QAC) disinfectant wipes (e.g., CaviWipes or Quat-Stat) and allow 1–2 minutes of contact time.

After disinfection, rinse the probe again with clean water to remove any residual disinfectant and prevent chemical contamination.

3.2 Inspection and Calibration

Inspect the probe surface to ensure it is smooth and free of scratches. Scratches can impair ultrasonic signal transmission and measurement accuracy.

If damage is found, promptly replace the probe.

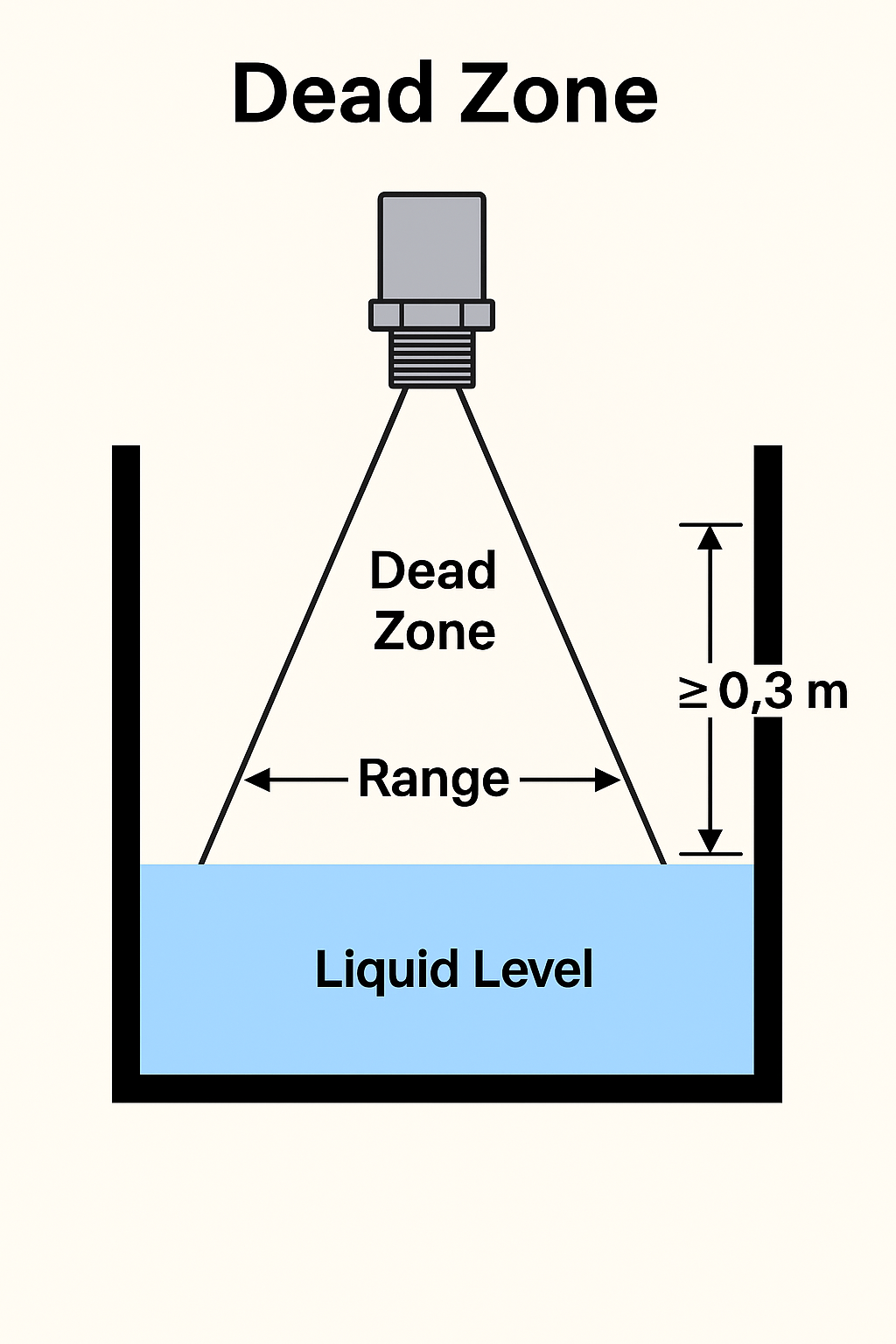

After reinstallation, perform zero-point calibration and range verification to ensure accuracy (target measurement error ≤ ±2mm).

4. Important Precautions

4.1 Prohibited Operations

Do not use hard tools (e.g., metal scrapers) or corrosive chemicals (e.g., acetone, hydrochloric acid).

Never submerge the probe in liquid to prevent internal moisture ingress and circuit damage.

4.2 Environmental and Cleaning Frequency Considerations

In high-humidity or dusty environments, shorten the cleaning cycle to once every 1–2 weeks.

Clean immediately after use to prevent long-term buildup that could cause signal attenuation.

5. Typical Application Scenarios and Cleaning Recommendations

| Application Scenario | Key Cleaning Points |

|---|---|

| Dairy Storage Tank Probes | Rinse daily with clean water; disinfect weekly with QAC wipes to prevent bacterial growth caused by milk fat residues. |

| Juice Filling Line Probes | Clean immediately after shutdown to remove sugary residues and prevent crystallization on the acoustic surface. |

| High-Temperature Cooking Tank Probes | For split-type designs, only clean the probe portion. The electronic unit is protected via shielded cables. |

Conclusion

By adhering to a systematic and thorough cleaning process, users can significantly extend the service life of ultrasonic level sensor probes. Proper maintenance ensures sanitary operation in food production environments and maintains the high precision required for level measurement.

Strict compliance with these guidelines helps safeguard product quality, meet hygiene standards, and enhance production efficiency.