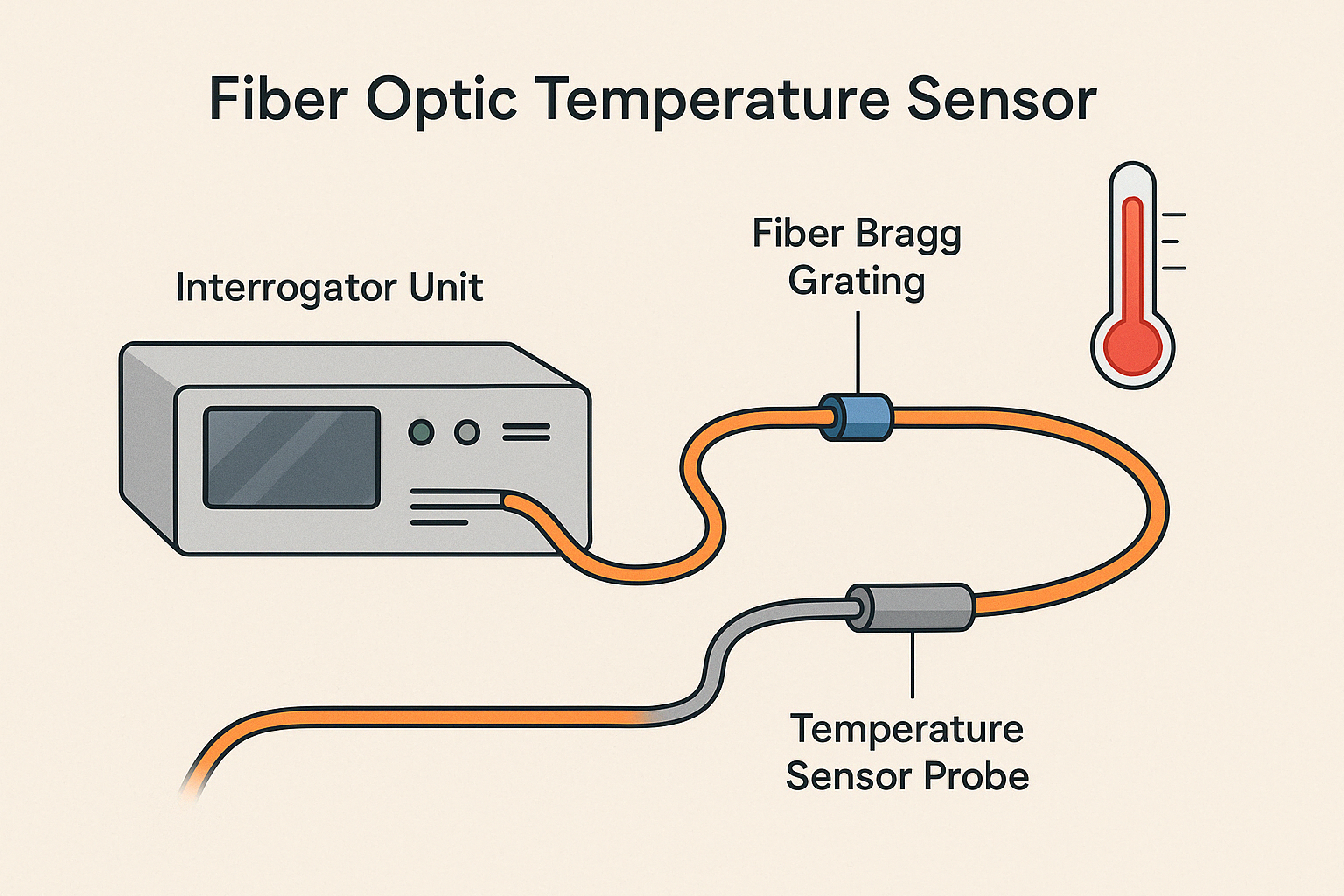

1. What Is a Fiber Optic Temperature Sensor?

A fiber optic temperature sensor is a temperature measurement device that uses optical fibers as the sensing medium. Unlike traditional electrical temperature sensors (e.g., thermocouples, RTDs), fiber optic sensors offer significant advantages such as immunity to electromagnetic interference (EMI), high-temperature resistance, compact size, and distributed measurement capability.

They are widely used in power systems, oil & gas, aerospace, medical applications, and other critical environments.

2. Working Principles

Fiber optic temperature sensors operate based on changes in light properties as it travels through the fiber. The key sensing mechanisms include:

2.1 Brillouin Scattering

Temperature changes affect the frequency shift of the scattered light in the fiber.

Suitable for long-range distributed temperature sensing (up to 100 km).

2.2 Raman Scattering

Utilizes the intensity ratio between Stokes and anti-Stokes light, which varies with temperature.

Commonly used in Distributed Temperature Sensing (DTS) systems.

2.3 Fiber Bragg Grating (FBG)

Temperature causes a wavelength shift in the reflected light.

Suitable for high-precision point or quasi-distributed sensing.

3. Major Types and Applications

| Type | Sensing Principle | Key Features | Application Scenarios |

|---|---|---|---|

| FBG Sensor | Wavelength shift | Fast response, high accuracy | Transformers, motors, structural health monitoring |

| Raman-based DTS | Scattered light | Long-distance distributed sensing | Oil wells, cable tunnels, perimeter monitoring |

| Brillouin-based Sensor | Frequency shift | Measures both temperature & strain | Railways, bridges, pipelines |

4. Advantages and Limitations

✅ Advantages

Passive sensing: No electrical power required at the sensing point, ideal for explosive environments.

EMI immunity: Excellent performance in high-voltage or strong magnetic fields.

High accuracy: Typically ±0.1°C or better.

Long-range monitoring: Distributed sensors can cover kilometers.

Miniaturization: Suitable for compact or embedded applications.

❌ Limitations

Relatively higher cost than traditional sensors.

Requires specialized installation and calibration.

Some types (e.g., Raman-based) may have slower response times.

5. Typical Applications

Power Transformers

Fiber optic sensors are embedded in transformer windings for real-time hot spot temperature monitoring.Oil & Gas Wells

DTS systems monitor the thermal profile of downhole environments over thousands of meters.Data Centers

Optical cables placed along cable trays detect local overheating, preventing fire risks.Medical Applications

Miniature sensors used for temperature mapping in MRI machines or thermal ablation procedures.

6. Selection Guide

When selecting a fiber optic temperature sensor, consider the following:

Measurement Type: Point sensing (FBG) or distributed sensing (Raman/Brillouin).

Temperature Range: Ensure compatibility with high-temperature environments.

Environment: Evaluate EMI, flammable gas, or corrosive risk factors.

Measurement Length: Consider long-distance support if required.

Budget & Integration: Account for system cost and compatibility with DAQ platforms.