1. Overview of Push Buttons

A push button is a type of manual control switch that is actuated by applying pressure using a part of the human body—typically the finger or palm. Equipped with a built-in spring mechanism for resetting, it is one of the most commonly used control devices in industrial and electrical systems.

Push buttons typically operate in control circuits with small currents (generally not exceeding 5A). They do not directly control high-current main circuits. Instead, they send control signals to devices such as contactors or relays, which in turn manage the switching, function conversion, or interlocking of the main circuit.

Typical Applications Include:

Motor start/stop controls

Circuit breaker operations in distribution panels

Automated process control in industrial systems

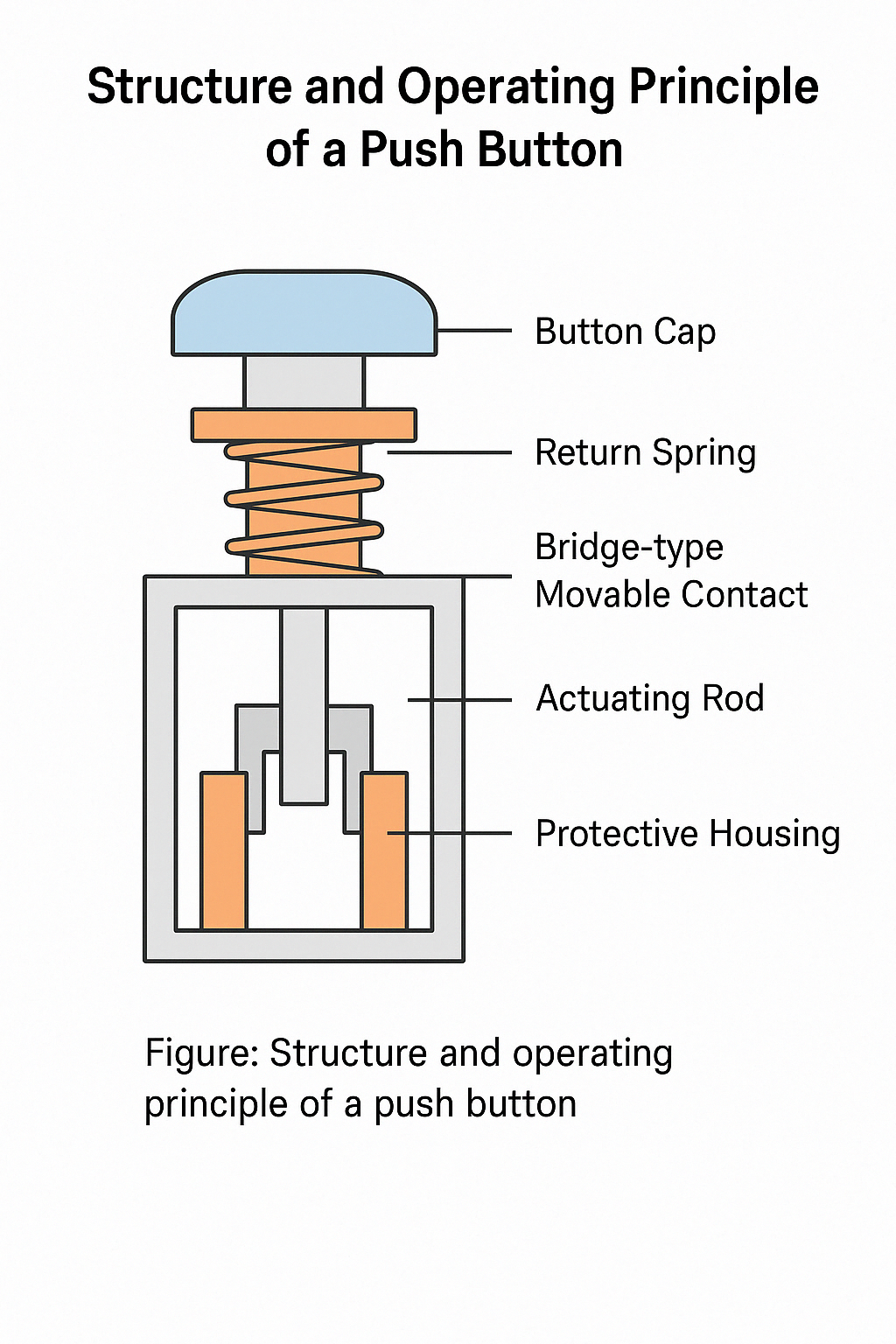

2. Structure and Operating Principle

A typical push button is composed of the following parts:

Button cap

Return spring

Bridge-type movable contact

Fixed contacts

Actuating rod

Protective housing

Contact Types Based on Resting State (No External Force):

Normally Closed (NC) or Stop Button: Opens upon pressing

Normally Open (NO) or Start Button: Closes upon pressing

Composite Button: Combines both NO and NC contacts in one device

When a force is applied, the internal contacts change state, altering the electrical continuity of the circuit.

3. Classification of Push Buttons

3.1 Based on Protection and Functionality

| Code | Type | Description & Application |

|---|---|---|

| K | Open Type | No protective shell, suitable for dry indoor panels |

| H | Protective Type | Transparent shield for safety, ideal for factory environments |

| S | Waterproof Type | Sealed against water, suitable for outdoor use |

| J | Emergency Type | Red mushroom-style cap for quick emergency shutdown |

| Y | Key Type | Requires a special key, used in critical systems to avoid misuse |

| F | Corrosion-Proof | Designed to resist chemical corrosion |

| X | Rotary Type | Operated by rotating knob, toggles between ON/OFF |

| D | Illuminated Type | Built-in indicator light for status display |

3.2 Based on Contact Configuration

Single-Contact Button: One NO or NC contact, used for simple control circuits

Dual-Contact (Composite) Button: Contains both NO and NC contacts, supports interlocking or self-hold circuits

Illuminated Button (D-Type): Integrated LED for visual feedback and status monitoring

4. Guidelines for Button Selection

4.1 Functional Requirements

Operation Method:

Frequent operation: Use spring-return type

Status-hold needed: Use latch-type/self-locking design

Indication Need:

Use D-type (illuminated) buttons to show operational status

Safety Considerations:

Emergency stop buttons must be red mushroom heads (J-type) with an actuation force ≥ 2N (as per GB/T 14048.5)

4.2 Environmental Adaptability

Corrosive Environments: Use F-type with corrosion-resistant housing

Wet/Dusty Conditions: Choose products with IP54–IP65 protection rating

Extreme Temperatures:

50°C: Heat-resistant plastics

<-20°C: Avoid plastic that may become brittle

4.3 Electrical Parameters

Current Rating: Typical ≤5A; for larger loads, use relay-assisted switching

Voltage Rating:

AC 380V requires ≥500V-rated buttons

DC systems require polarity-specific designs

Mechanical Durability:

General use: ≥100,000 cycles

Precision systems: ≥500,000 cycles

4.4 Color Code Recommendations

| Button Function | Recommended Color |

|---|---|

| Start | White, Green, or Black (preferably White) |

| Stop | Black, White, or Red (preferably Black) |

| Emergency Stop | Red only |

| Indicator (Status) | Typically Green (RUN) / Red (STOP) |

5. Application Case Study

Scenario: Motor control for a chemical reactor stirring system

Conditions:

Ambient temperature: 45°C

Acidic vapors present

50 daily start/stop cycles

Selection Process:

Protection Needs: Corrosion-proof (F-Type) + IP55 enclosure

Control Requirements: Composite button for self-locking

Safety Feature: Separate red mushroom-type emergency stop button (J-Type)

Electrical Specs: AC 220V, 5A load with a green LED indicator

Final Selection:

LAY1-01 corrosion-resistant composite button

J-Type emergency stop module

D-Type indicator light included

6. Common Failures and Troubleshooting

| Problem | Cause | Solution |

|---|---|---|

| Contact Sticking | Arcing and oxidation on contacts | Polish with fine sandpaper; replace with silver-nickel contacts if worn |

| Frequent Misoperation | Accidental presses or loose installation | Add mechanical interlocks or dual-button activation logic |

| Indicator Light Failure | Burnt-out LED or overvoltage | Replace with low-power LED (<5mA); install limiting resistor |

7. Conclusion

Push buttons, though simple in appearance, are crucial components in industrial control circuits. Their proper selection and maintenance directly impact equipment safety, reliability, and usability. By understanding button classifications, design principles, and environmental considerations, engineers can ensure optimal control system performance across a variety of industrial settings.