1. What Is an Electrical Schematic Diagram?

An electrical schematic diagram (also known as a wiring diagram or circuit diagram) is a visual representation of an electrical system. It illustrates how various electrical components are connected and how current flows through the system. These diagrams serve as the foundational reference for electrical design, installation, commissioning, maintenance, and fault diagnosis.

2. Key Functions of a Schematic Diagram

Visualizes the working logic of an electrical system

Guides the installation and wiring of control equipment

Assists in troubleshooting and system maintenance

Provides a reference for production and quality inspection

3. Structural Features of a Typical Diagram

Drawn according to control logic, not physical layout

Vertical lines represent control circuits (top to bottom)

Horizontal lines represent power supply circuits (left to right)

The power source is typically placed at the top left or upper section

Control elements (e.g., buttons, relays) are arranged above actuating elements (e.g., motors)

4. Common Electrical Symbols and Meanings

| Component | Symbol (Textual Representation) | Function / Description |

|---|---|---|

| AC/DC Power Supply | ~ / ⎓ | AC or DC voltage source |

| Fuse | ─[ ]─ | Circuit overload protection |

| Switch | ─o/ o─ | Turns circuit ON/OFF |

| Push Button (NO) | ─( )─ | Normally open contact for start operation |

| Contactor Coil | ─( KM )─ | Main control element in motor circuits |

| Contactor Contacts | ─[ ]─ or ─[/]─ | Normally open / closed auxiliary contacts |

| Thermal Overload Relay | ─( FR )─ | Protects motor from overload |

| Motor | ─( M )─ | Final execution device |

| Intermediate Relay | ─( KA )─ | Auxiliary control element |

5. How to Read and Understand a Schematic Diagram

Step-by-Step Approach:

Step 1 – Locate the Power Supply Section

Usually at the top-left of the diagram

Identify voltage and type (e.g., 220V AC, 24V DC)

Step 2 – Identify the Control Circuit

Find push buttons and see how they link to relay coils or contactors

Step 3 – Analyze the Logic

For example:

Pressing the “Start” button energizes the KM coil

KM’s main contact closes → Motor runs

Pressing “Stop” button breaks circuit → KM de-energizes → Motor stops

Step 4 – Trace the Actuating Circuit

Follow the path from power to motor

Ensure contactors or protection devices are correctly placed

Step 5 – Evaluate Protection Components

Look for fuses, thermal relays, and circuit breakers

Check their positions in series with motors or control devices

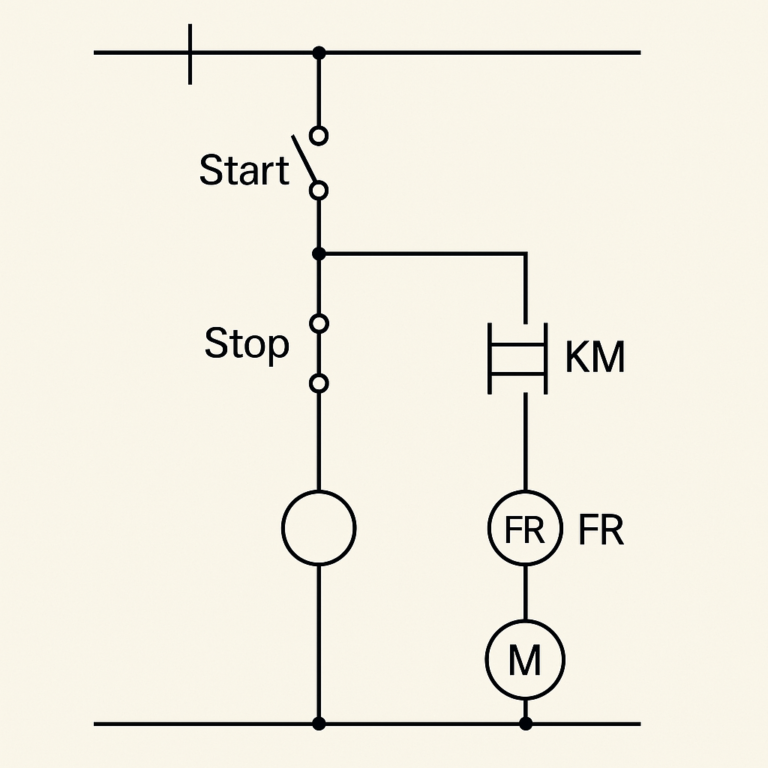

6. Practical Example: Motor Start-Stop Control Circuit

Objective:

Start the motor with a normally open push button and stop it with a normally closed push button. Include a self-holding circuit for automatic retention.

Key Components:

SB1 – Start button (NO)

SB2 – Stop button (NC)

KM – Contactor with auxiliary contact

FR – Thermal overload relay

M – Motor

Operation Logic:

Press SB1 → KM coil is energized

KM’s main contact and auxiliary contact close

Releasing SB1 → KM stays energized via its auxiliary contact (self-holding)

Press SB2 → KM coil de-energizes → Contacts open → Motor stops

7. Schematic Diagram vs. Wiring Diagram

| Category | Schematic Diagram | Wiring Diagram |

|---|---|---|

| Purpose | Logical operation representation | Actual wiring and physical connections |

| Layout | Abstract, logic-based | Real-world layout and positions |

| Audience | Engineers, designers, maintenance staff | Installers, assembly technicians |

| Element Position | Symbolic and functional | Accurate to real-world location |

8. Learning Recommendations

Master standard symbols based on GB/T 4728 or IEC standards

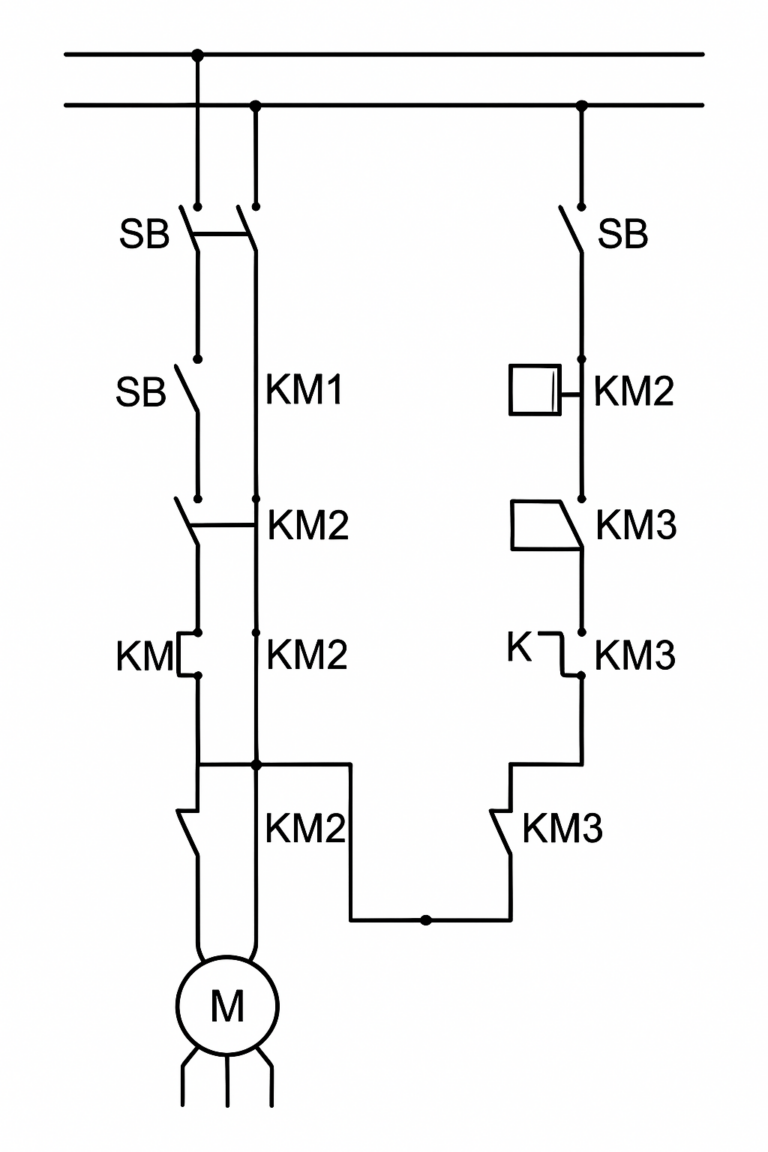

Start with simple circuits such as motor control, relay logic, and star-delta starters

Combine study with actual control cabinet wiring diagrams

Use simulation software like Multisim, EPLAN, or PLC simulators for hands-on practice