1. Overview

The Christmas Tree system is a critical component in oil and gas extraction, responsible for regulating flow and pressure at the wellhead to ensure safe and efficient production. Accurate liquid level measurement within this system plays a vital role in optimizing production efficiency and avoiding equipment damage or safety hazards.

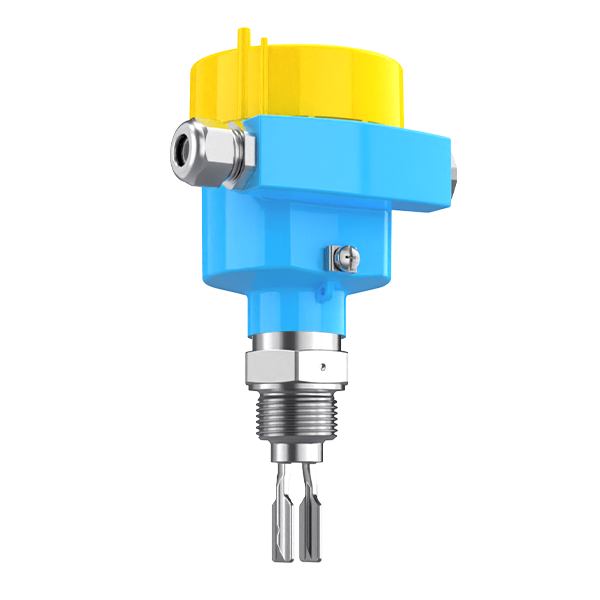

To meet these demanding requirements, the Ring-11 Tuning Fork Level Switch has emerged as a high-performance solution. Thanks to its precision, durability, and adaptability to harsh environments, it is widely adopted in oilfield applications.

2. Challenges in Christmas Tree Level Measurement

Liquid level monitoring in oil well Christmas Tree systems faces a series of technical challenges:

Extreme Temperatures: Wellbore temperatures can reach several hundred degrees Celsius, pushing conventional instruments beyond their limits.

High Pressure and Corrosive Media: Fluids often contain corrosive gases or chemicals, requiring sensors to withstand aggressive conditions.

Vibrations and Electrical Noise: Harsh environments can introduce interference that impacts measurement accuracy.

Limited Maintenance Opportunities: Systems often operate in remote or offshore locations, demanding long-term stability with minimal maintenance.

Traditional float, capacitive, or pressure-based level sensors often struggle under these conditions. In contrast, the Ring-11 tuning fork switch offers a robust, field-proven alternative.

3. Advantages of the Ring-11 Tuning Fork Level Switch

✅ High Measurement Reliability

Ring-11 uses a vibration-based tuning fork principle. When immersed in liquid, the fork’s resonant frequency shifts due to changes in mass and damping. This allows for highly accurate and repeatable liquid level detection, even under fluctuating process conditions.

✅ Excellent High-Temperature Resistance

Designed for extreme environments, Ring-11 can operate reliably at temperatures up to 280°C, making it suitable for deep well operations and superheated oil recovery systems.

✅ Superior Corrosion Resistance

Constructed from high-grade corrosion-resistant materials such as 316L stainless steel or Hastelloy, Ring-11 maintains long-term performance in wells containing hydrogen sulfide, chlorides, or other aggressive substances.

✅ Strong Anti-Interference Capability

Thanks to its smart signal processing and mechanical stability, the Ring-11 performs reliably in environments with intense mechanical vibrations and electromagnetic interference.

✅ Low Maintenance Requirements

With no moving parts and a rugged design, the Ring-11 requires minimal calibration or upkeep. This reduces operational downtime and overall maintenance costs — a major advantage in offshore or inaccessible well locations.

4. Application Scenarios

In oilfield operations, the Ring-11 Tuning Fork Level Switch is commonly installed in:

Wellhead separators

Production manifolds

Safety shutdown systems

Emergency drainage tanks

It provides real-time level signals to the control system, triggering alarms or shutdowns when liquid levels exceed safe thresholds. This prevents overfilling, dry run conditions, or equipment damage — ensuring safe, continuous operation of the Christmas Tree system.

5. Conclusion

Liquid level measurement in oil well Christmas Tree systems requires a sensor that can thrive in high-pressure, high-temperature, and corrosive conditions — while delivering precision, durability, and minimal maintenance.

The Ring-11 Tuning Fork Level Switch delivers on all these fronts, making it a top-tier solution for engineers seeking high-reliability instrumentation in complex oilfield environments.

📌 Choose Ring-11 to ensure safer, more efficient oil extraction with real-time, reliable level control.