Introduction

In piping systems, selecting the correct pipe size is essential for ensuring compatibility, safety, and optimal performance. However, confusion often arises around the term “Nominal Diameter” (DN) and its relationship with a pipe’s outer diameter (OD) and inner diameter (ID). This article aims to clarify these concepts and provide practical guidance for selecting and interpreting pipe dimensions in engineering applications.

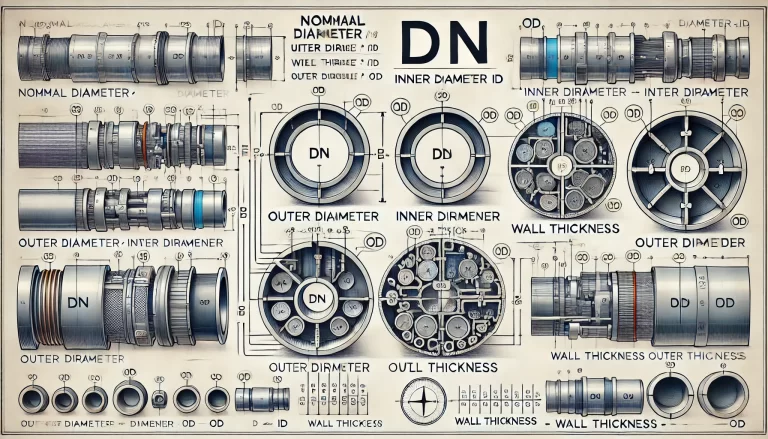

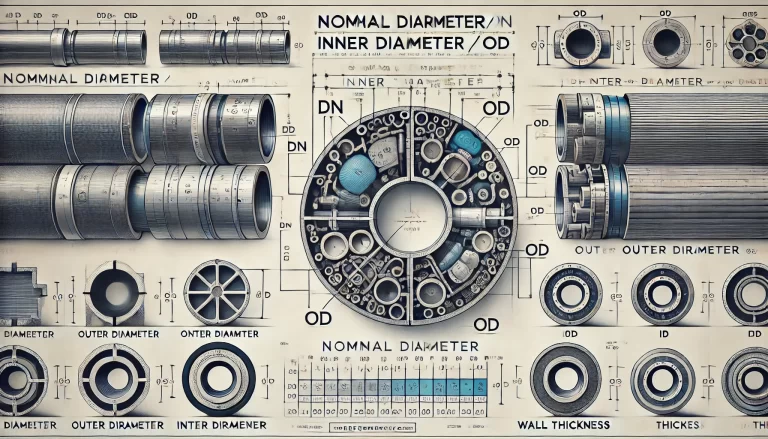

1. What Is Nominal Diameter (DN)?

The Nominal Diameter (DN) is a standardized designation used to identify the size of components in piping systems. It is represented as DN followed by a dimensionless number (e.g., DN50, DN100).

🔎 Note: The DN number does not correspond directly to any physical measurement. It is a conventional reference size and should not be used for calculations unless defined by relevant standards.

2. Definition of Inner and Outer Diameters

Inner Diameter (ID): The actual diameter of the pipe measured from the internal wall to the opposite internal wall. This value determines the flow capacity of the pipe.

Outer Diameter (OD): The actual external diameter of the pipe, measured from one outer wall to the opposite outer wall. This dimension is critical for fitting, support, and installation.

3. DN vs OD and ID – How They Relate

A. Relationship Between DN and OD

Although DN does not directly represent the OD, there is a general estimation:

DN ≈ OD – 2 × wall thickness

However, this is a rough estimate, and actual values may vary depending on wall thickness and manufacturing standards.

B. Relationship Between DN and ID

The DN value is usually closer to the inner diameter, especially for thin-walled pipes. However, the actual inner diameter varies with wall thickness, which differs across pipe schedules or pressure classes.

4. Sample DN to OD Reference Table

To illustrate this relationship, here is a simplified table showing typical OD and estimated ID values for selected nominal pipe sizes:

| Nominal Diameter (DN) | Outer Diameter (OD) [mm] | Estimated Inner Diameter (ID) [mm] |

|---|---|---|

| DN20 | 26.9 | 20–22 |

| DN25 | 33.7 | 25–29 |

| DN40 | 48.3 | 40–44 |

| DN50 | 60.3 | 50–55 |

| DN80 | 88.9 | 78–83 |

| DN100 | 114.3 | 100–108 |

| DN150 | 168.3 | 150–160 |

| DN200 | 219.1 | 200–210 |

| DN300 | 323.9 | 300–310 |

| DN400 | 406.4 | 380–395 |

⚠ These values are indicative only. Always refer to product datasheets and national/international standards for precise specifications.

5. Pipe Size Marking by Material Type

Different materials have different conventions for pipe dimension designation. Here is a summary:

| Pipe Material Type | Recommended Size Indication |

|---|---|

| Galvanized/non-galvanized steel pipes, cast iron | Nominal Diameter (DN) |

| Seamless/welded steel pipes, stainless steel, copper | Outer Diameter × Wall Thickness |

| Concrete, ceramic, clay pipes | Inner Diameter (d) |

| Plastic pipes | As per product standards |

6. Key Takeaways

DN is a reference size, not a measurement.

DN values are more aligned with inner diameters, but actual IDs vary based on wall thickness.

The outer diameter remains constant for a given DN across schedules, but the ID changes.

Always refer to manufacturer data or relevant standards (e.g., ISO, ANSI, GB) when selecting pipes.

Conclusion

Understanding the distinctions between DN, OD, and ID is crucial for engineers, designers, and procurement professionals in selecting the right piping components. While DN serves as a standardized system for identification and compatibility, it should not be used as a substitute for actual physical measurements. Always consult technical datasheets and applicable standards to ensure accuracy and proper fit in your piping system design.