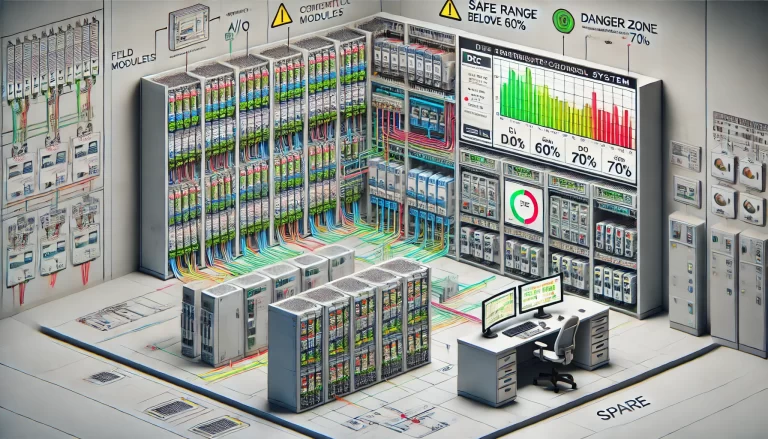

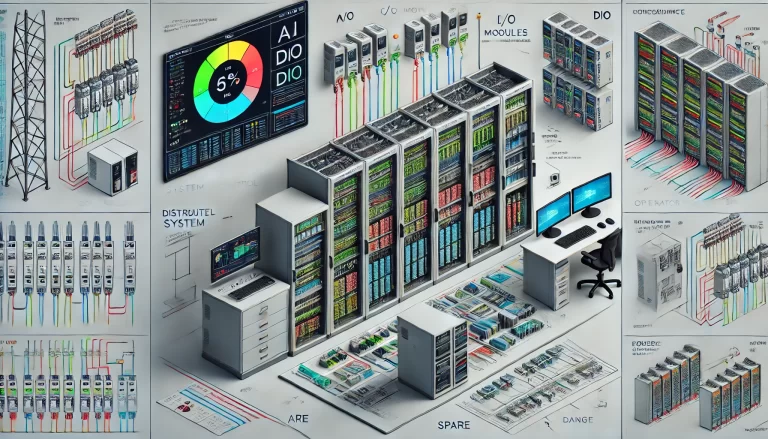

In industrial automation projects, Distributed Control Systems (DCS) serve as the backbone of plant operations. Proper planning for I/O (Input/Output) modules and controller spare capacity is critical for ensuring system scalability, reliability, and maintenance flexibility. Overlooking this aspect can result in serious challenges during plant expansion or system upgrades.

This article provides a detailed guide on best practices for determining the appropriate spare I/O modules and controller margins in a DCS setup.

1. Spare Capacity for I/O Modules

✅ General Recommendation: Reserve 10%–20% Spare I/O Channels

Each type of I/O signal—Analog Input (AI), Analog Output (AO), Digital Input (DI), and Digital Output (DO)—requires careful spare planning:

| I/O Type | Recommended Spare Percentage |

|---|---|

| AI / AO | 15%–20% |

| DI / DO | 10%–15% |

📌 Additional Notes:

For systems with expected future expansion, consider the higher end of the percentage range.

It’s best to add a full spare I/O module rather than leaving only 1–2 channels unused on an existing module. This avoids fragmentation and simplifies future maintenance.

For remote I/O systems or safety instrumented systems (SIS), dedicated spares are often required as per industry standards (e.g., IEC 61511).

2. Controller Capacity and CPU Load

A DCS controller’s performance depends on its CPU utilization, memory usage, and scan cycle time. Overloading a controller can lead to performance degradation, delays in control loops, and even system crashes.

✅ Best Practice: Keep Controller CPU Load Below 50%–60%

| Design Stage | Recommendation |

|---|---|

| During FAT/SAT | CPU load ≤ 50% |

| After Commissioning | CPU load ≤ 60% |

| Under Max Load | Never exceed 70% to avoid risk |

Key Considerations:

Scan Time Margin: Critical control loops may require fast scan times (e.g., ≤ 500ms). Spare capacity helps maintain scan time even during high loads.

Engineering Margin: Leave enough processing margin to add new logic or functions later without requiring a controller upgrade.

Redundant Controllers: For high-reliability systems, redundant controllers (Primary + Backup) are recommended to ensure system continuity.

3. Practical Guidelines Based on Project Size

| Project Size | Total I/O Points | Spare I/O Recommendation | Controller Load Margin |

|---|---|---|---|

| Small | < 500 | 10%–15% | CPU ≤ 50% |

| Medium | 500–2000 | 15%–20% | CPU ≤ 50% |

| Large | > 2000 | 20%+, consider spare modules | Use redundant controllers |

In large-scale projects, it’s common to dedicate entire spare I/O modules and empty rack slots for future expansions. This avoids needing to re-cable or physically reconfigure the system during upgrades.

4. Other Factors to Consider

Physical Slot Space: Ensure the I/O chassis has empty slots for additional modules.

Power Supply Margin: Spare modules will add power load—make sure the power supply has a 20% margin.

Licensing: Some DCS platforms restrict the number of usable I/O points or function blocks based on license level—plan ahead.

Field Wiring: Use terminal blocks and marshalling cabinets with spare terminals (about 10%–20%) to accommodate future wiring.

5. Summary Recommendations

| Item | Recommended Spare Capacity |

|---|---|

| AI/AO Modules | 15%–20% spare channels |

| DI/DO Modules | 10%–15% spare channels |

| Controller CPU Load | Target ≤ 50% (max 60–70%) |

| Chassis Slot Space | Reserve slots for future modules |

| System Power Supply | 20% capacity margin |

| Engineering License | Plan based on long-term I/O count |

Final Thoughts

Including adequate spare capacity in a DCS system is not just good engineering practice—it’s cost-effective insurance for long-term plant flexibility. While upfront investment in spare modules and higher-spec controllers may seem excessive, it prevents costly downtime and re-engineering when expansions or modifications are needed later.