Choosing the appropriate flow meter for an industrial application is crucial to ensure accurate, stable, and cost-effective flow measurement. Flow meters come in many types and models, each suited to specific fluids, process conditions, and performance requirements.

This guide will walk you through the essential steps and considerations for selecting the most suitable flow meter for your application.

1. Define Measurement Objectives and Requirements

a. Identify the Type of Fluid

Start by specifying the fluid to be measured. Is it a liquid, gas, or steam? You also need to understand its specific characteristics:

Corrosive or non-corrosive

Conductive or non-conductive

Viscous, clean, or contaminated

Particulate content or bubbles

Examples:

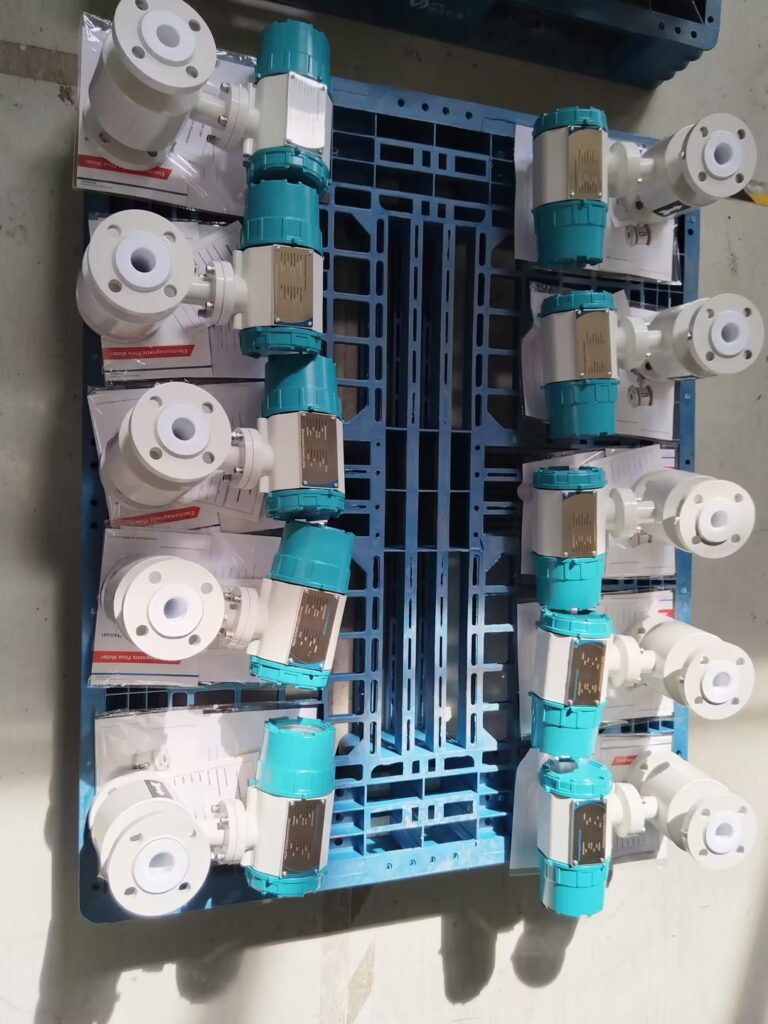

Electromagnetic flow meters are ideal for conductive liquids like wastewater or slurries.

Coriolis mass flow meters are well-suited for high-viscosity or non-Newtonian fluids, offering high-accuracy mass flow measurement.

b. Determine the Flow Range

Define both the maximum and minimum flow rates expected in your process. Ensure the selected flow meter covers this range while maintaining good accuracy.

Tip: For best performance, ensure that the normal operating flow falls within 30%–70% of the flow meter’s full-scale range.

Example: If your water flow ranges from 10 m³/h to 100 m³/h, choose a flow meter with a suitable measuring range to handle the variation accurately.

c. Define Accuracy Requirements

Measurement accuracy depends on your application. High-accuracy meters are more expensive, so choose according to the purpose:

| Application Type | Recommended Accuracy | Suitable Meter Type |

|---|---|---|

| Trade settlement, custody transfer | ±0.5% or better | Turbine, Coriolis, ultrasonic |

| Process monitoring | ±2% – ±5% | Vortex, differential pressure |

2. Consider Installation Conditions

a. Pipe Size and Meter Size

The flow meter’s diameter should typically match the process pipeline. However, in special cases, you might choose a reduced bore (smaller than pipe) or expanded bore (larger than pipe) design for measurement stability.

Example: In large-diameter pipes, using a smaller flow meter with a reducer pipe may improve accuracy.

b. Installation Space

Ensure that there’s enough physical space (length, width, and height) for the meter and any required upstream/downstream straight pipe sections.

Examples:

Ultrasonic flow meters often need longer straight pipe runs to ensure laminar flow.

Variable area (rotameter) meters require vertical space for installation.

c. Orientation and Mounting

Some meters have strict installation requirements:

Electromagnetic flow meters should be mounted horizontally and must stay full of liquid during operation.

Vortex flow meters offer more flexible orientation but still require proper inlet/outlet straight pipe lengths to avoid turbulence.

3. Evaluate Environmental Factors

a. Operating Temperature and Pressure

Verify the fluid’s temperature and pressure. Select meters that can withstand those conditions:

Steam measurement requires meters like orifice plates or vortex flow meters designed for high pressure and temperature.

For low-temperature fluids, ensure the materials won’t become brittle or fail.

b. Humidity and Corrosive Atmospheres

For humid or chemically aggressive environments, choose meters with appropriate IP protection ratings and corrosion-resistant materials.

Teflon-lined electromagnetic meters are suitable for aggressive chemical flows.

Enclosures should be waterproof or explosion-proof depending on the site condition.

c. Electromagnetic Interference (EMI)

Strong EMI sources like motors or transformers may interfere with some flow meters. Select models with shielding and EMI-resistant circuit designs (e.g., industrial-grade magnetic flow meters).

4. Consider Economic Factors

a. Initial Purchase Cost

Flow meters vary widely in cost. Choose a meter that meets your performance needs without over-engineering the solution.

| Meter Type | Cost Level | Notes |

|---|---|---|

| Coriolis, Ultrasonic | High | High accuracy, expensive, for critical systems |

| Electromagnetic | Medium | Great for conductive liquids, cost-effective |

| Orifice, Vortex | Low | Simple design, cost-saving for basic monitoring |

b. Operating and Maintenance Cost

Factor in energy consumption, service intervals, and spare part availability.

Electromagnetic meters have low energy use but may require cleaning electrodes.

Vortex meters have no moving parts—lower maintenance, but may struggle at low flows.

c. Service Life

Investing in a durable, high-quality meter reduces long-term cost and replacement frequency.

Example: Metal tube variable area meters offer long service life and robust construction for tough environments.

5. Other Important Considerations

a. Signal Output and Communication

Check your control system’s needs:

Analog (4–20mA) for basic systems

Pulse output for batch control

Digital protocols like HART, Profibus, Modbus, Foundation Fieldbus for smart systems and remote data transmission

For DCS or SCADA integration, digital communication is often preferred.

b. Brand Reputation and After-Sales Support

A reliable supplier offers better quality assurance and long-term technical support.

Recommended Brands:

Emerson

Yokogawa

Siemens

Endress+Hauser

ABB

- Zero Instrument

These brands have global service networks and proven performance across industries.

✅ Conclusion

Choosing the right flow meter is a multi-step process that involves understanding your fluid, process conditions, installation constraints, and budget. There’s no one-size-fits-all solution. The best flow meter is the one that matches your specific application technically, economically, and operationally.

If you’re unsure, consult a professional instrumentation supplier or integrator to avoid costly mistakes and ensure reliable long-term performance.