When selecting a flow meter, it is crucial to deeply understand the principles of various flow meters and the characteristics of fluids. Consideration must also be given to the specific conditions at the installation site and surrounding environmental factors. Economic considerations should not be overlooked. Typically, the selection process should focus on the following key aspects:

Performance Requirements of the Flow Meter: Identify the accuracy, range, and response time required based on the application needs.

Fluid Characteristics: Consider the type of fluid (liquid, gas, or slurry), its viscosity, conductivity, temperature, and chemical compatibility with flow meter materials.

Installation Requirements: Different types of flow meters have different installation needs. For instance, differential pressure flow meters and velocity flow meters often require straight pipe runs upstream and downstream to ensure fully developed flow at the meter inlet. On the other hand, positive displacement and float flow meters are less demanding in terms of straight pipe requirements.

Environmental Conditions: The meter must withstand the operating environment such as temperature extremes, humidity, and potential for exposure to corrosive or explosive atmospheres.

Cost: Consider both the initial purchase price and the long-term operating and maintenance costs.

Detailed Installation Considerations:

Orientation and Flow Direction: The installation orientation (vertical or horizontal) can affect performance. For example, downward vertical flow can exert extra force on flow meter sensors, affecting accuracy and repeatability.

Upstream and Downstream Piping: Flow disturbances caused by bends, valves, or other fittings need to be minimized with sufficient straight piping or the use of flow conditioners.

Valve Placement: Control valves should generally be placed downstream of the meter to avoid disturbances and cavitation within the meter.

Protection Accessories: Installing filters upstream of meters like turbine and positive displacement flow meters can prevent damage and ensure accurate readings.

Recommendations for Specific Flow Meter Types:

Coriolis Mass Flow Meters are excellent for applications requiring high accuracy and are largely immune to the effects of the flow profile and fluid properties changes.

Turbine Flow Meters work well for clean, medium to high-speed flows of low-viscosity fluids.

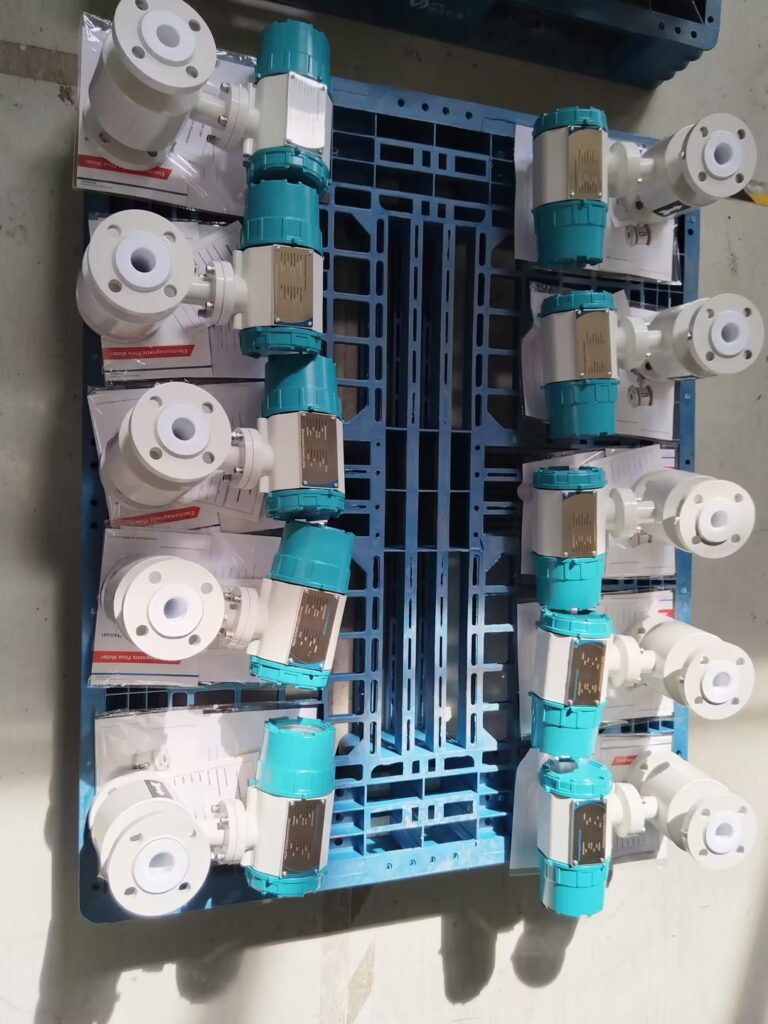

Electromagnetic Flow Meters are ideal for conductive fluids and offer advantages in dirty or corrosive applications.

Ultrasonic Flow Meters are suitable for applications where the fluid cannot be contaminated, such as in the food and pharmaceutical industries.

Vortex Flow Meters are suitable for a wide range of temperatures and pressures and are effective for steam flow measurements.

In conclusion, choosing the right flow meter involves balancing technical requirements with economic factors. The recommendations provided here are based on typical industry applications but should be tailored to the specific needs of your project.