Temperature cycling, also known as thermal cycling, is a method of environmental stress testing that subjects materials or devices to alternating high and low temperatures. This test is crucial in assessing the thermal mechanical properties, durability of materials, and electrical stability of products under severe temperature fluctuations. Industries such as aerospace, electronics manufacturing, automotive, industrial automation, and military greatly rely on this test to ensure that their products maintain reliable performance under extreme conditions.

Principles of Temperature Cycling

The principle of temperature cycling lies in the physical property of thermal expansion and contraction. Materials expand when heated and contract when cooled, which can cause uneven deformation and thermal stress, impacting structural integrity and functional performance. Here’s a breakdown of the essential factors that define a temperature cycling test:

Temperature Range: The wider the temperature span, from the lowest to the highest point, the more intense the thermal stress imposed on the materials. For example, cycling between -55°C to 125°C imposes a greater mechanical impact than cycling between 0°C to 50°C.

Heating and Cooling Rates: Rapid temperature changes can lead to thermal shock, causing brittle materials to crack, whereas too slow rates might not adequately simulate real environmental changes.

Dwell Time: The length of time the temperature is held stable at the high and low points ensures that the material reaches thermal equilibrium, simulating long-term exposure to extreme temperatures.

Number of Cycles: Typically determined by the product’s expected lifecycle, ranging from dozens to thousands of cycles. More cycles can reveal potential fatigue damages.

Impacts of Temperature Cycling

Thermal Mechanical Fatigue: Metals, plastics, and composite materials undergo multiple expansion and contraction cycles under temperature changes. This can lead to interfacial delamination, microcracks, or even complete failures.

Damage to Welds and Electronic Components: Solder joints on printed circuit boards (PCBs) can develop microcracks from creep fatigue due to long-term temperature cycling, leading to cold solder or circuit breaks.

Degradation of Seals and Encapsulation Materials: Sealing materials like rubber and silicone can experience plastic flow and become brittle and crack under repeated temperature changes, compromising the seal integrity and leading to leaks.

Failure of Optical Components and Display Devices: Optical lenses and displays (LCD/OLED) can suffer from optical distortions and degeneration of the liquid crystals due to temperature shifts, severely affecting optical performance and display quality.

Variability in Insulating Materials and Electrical Properties: Cables and insulation materials may exhibit changes in dielectric constants and decreased insulation resistance, leading to corona discharge or electrical failures in high-voltage equipment.

Typical Applications of Temperature Cycling

Aerospace: Satellites and spacecraft must withstand the severe temperature differences encountered in orbit to ensure the reliability of structural materials, electronic systems, and thermal control devices.

Electronics Manufacturing: Essential components like microprocessors, memory chips, and power semiconductors are tested through temperature cycling to validate their soldering processes, encapsulation integrity, and long-term electrical performance.

Automotive Industry: Engine compartments in vehicles experience drastic temperature changes, requiring components like control units, sensors, vehicle batteries, and motors to undergo rigorous temperature cycling tests.

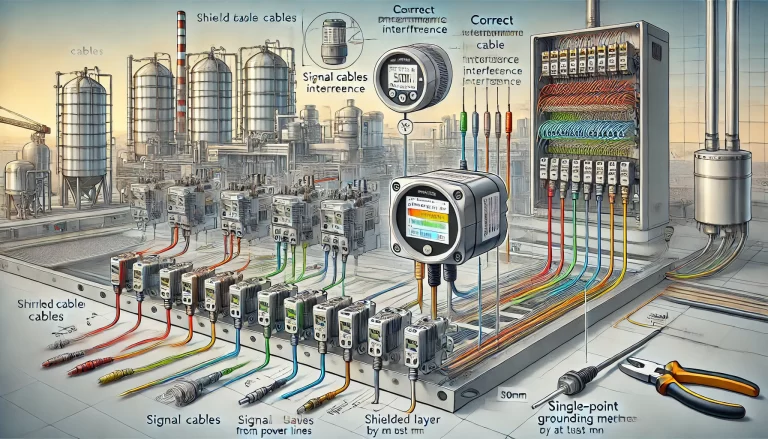

Industrial Automation: Field instruments such as level meters, pressure sensors, and actuators must maintain measurement stability and structural integrity even under significant temperature fluctuations and frequent on-off conditions.

Military and Specialty Equipment: Military equipment such as missiles, radars, and tanks operated in extreme environments like deserts or polar regions rely on temperature cycling tests to ensure operational performance and survivability.

Conclusion

Temperature cycling is not only a method for reliability assessment during product development but also a critical standard for verifying thermal stability, mechanical strength, and electrical performance. As new materials and technologies emerge, the methods and standards of temperature cycling tests will continue to evolve to meet more stringent environmental adaptability requirements, pushing industry product performance to higher levels of reliability.