1. Structure and Components

Core Elements:

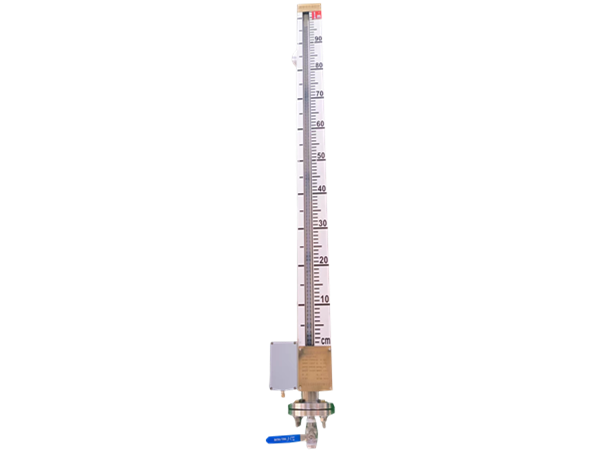

A magnetic level indicator with a remote transmitter primarily consists of the following components:

- Magnetic float

- Guide tube (main chamber)

- Reed switches or magnetoresistive sensors

- Remote sensing unit (transmitter)

- Signal processing module

- Local visual indicator (red/white flaps or rollers)

Mounting Method:

The transmitter sensor is typically mounted externally on the guide tube of the magnetic level indicator using clamp-on or strapped-on fixtures. This ensures close magnetic coupling with the internal float, allowing synchronized motion detection without direct contact.

2. Operating Principle

Float Movement:

As the liquid level in the vessel rises or falls, the magnetic float inside the main chamber moves accordingly. The permanent magnet embedded in the float magnetically couples with the external indicator, causing the red/white flaps to flip and visually indicate the level.

Signal Detection:

The movement of the float triggers nearby reed switches to open or close, altering the resistance in the signal chain. Alternatively, magnetoresistive sensors detect changes in the magnetic field to determine float position more precisely and continuously.

3. Signal Conversion and Output

Electrical Signal Generation:

The sensor array detects float position either through discrete reed switch activation or continuous magnetic field variation. These changes are converted into electrical signals, such as voltage or resistance, which are further processed by a signal conversion module.

Standardized Output:

The processed signal is typically output as a 2-wire 4–20 mA DC signal — a widely accepted industrial standard for process control. This allows seamless integration with PLCs, DCS systems, or other secondary instrumentation for remote monitoring, alarms, and automated control.

4. Application Scenarios

Suitable Equipment:

Magnetic level indicators with remote transmitters are ideal for various types of vessels, including:

- Columns

- Tanks

- Reactors

- Spheres

- Boilers

Industrial Sectors: They are widely used across industries such as:

- Oil & Gas

- Petrochemical

- Power Generation

- Environmental Engineering

- Food and Beverage

These systems are especially suited for applications requiring explosion-proofing, leak prevention, or operation in harsh environments.

5. Technical Specifications

| Parameter | Specification |

|---|---|

| Measuring Range | 200 mm – 15,000 mm |

| Accuracy | ±5 mm (high-precision) / ±10 mm (standard) |

| Power Supply | 24 V DC (industrial standard) |

| Output Signal | 4–20 mA, 2-wire loop |

| Operating Conditions | High temperature, high pressure, corrosive |

6. Classification and Model Selection

Functional Variants:

- Explosion-Proof Models (e.g., UDZ-3/B):

Designed for hazardous environments with flammable gases or liquids. - Insulated / Frost-Proof Models (e.g., UDZ-1W, UDZ-1S):

Feature jacketed enclosures for applications involving low temperatures or easily solidifying media. - Corrosion-Resistant Models:

Constructed with steel-plastic composite materials to handle strong corrosive chemicals.

Installation Types:

- Side-Mounted: Commonly used for tanks with accessible sides.

- Top-Mounted / Bottom-Mounted: Ideal for limited space or tall vertical vessels.

- Insertion-Type: For specific internal applications or retrofits.

7. Calibration and Precision Adjustment

Zero Point Calibration:

The float’s initial position is aligned with the indicator to establish a consistent zero-level reference, ensuring accurate coupling between mechanical display and electrical signal.

Signal Adjustment:

At both the zero and full-level points, the current output is fine-tuned to ensure:

- 4 mA corresponds to zero level

- 20 mA corresponds to full level

This ensures accurate linear correspondence between physical liquid level and transmitted signal for process control systems.

✅ Conclusion

The magnetic level indicator with remote transmitter offers a robust, dual-function solution — enabling both local visual indication and remote electrical signal output through a magnetically coupled, non-intrusive mechanism. Its modular design, flexible model configurations, and high reliability make it a preferred choice in demanding industrial environments. From high-pressure chemical reactors to cryogenic storage tanks, this technology provides accurate, safe, and maintenance-friendly level monitoring.