Introduction: The Importance of Sewage Pump Level Sensors

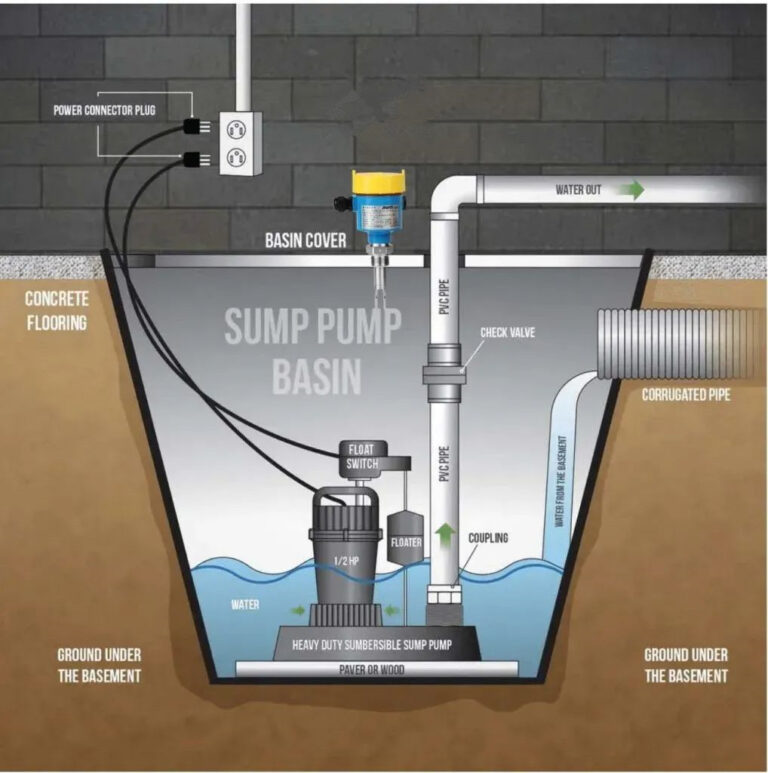

Sewage pumps play a crucial role in preventing flooding in basements and low-lying areas by efficiently managing wastewater levels. To ensure optimal performance, reliable sewage pump level sensors are essential. These sensors monitor the liquid level inside sewage pits, automatically activating the pump when the water rises and shutting it down once the level decreases. This automated control system improves efficiency, reduces energy consumption, and extends the lifespan of the pumps.

While traditional float switches have been widely used for liquid level detection, advanced technologies such as tuning fork level switches and radar level sensors are gaining popularity due to their superior accuracy, reliability, and durability, particularly in challenging environments where traditional methods often fail.

Understanding Sewage Pump Level Sensors

Sewage pump level sensors are designed to detect water levels within a sump pit. Their primary function is to send a signal to the pump control system to initiate pumping when water reaches a predetermined level and to stop the pump once the water level drops.

A well-functioning level sensor system offers the following benefits:

- Automatic water management – Reducing manual monitoring and intervention.

- Increased pump longevity – Preventing unnecessary wear and tear by avoiding frequent short cycling.

- Enhanced energy efficiency – Reducing power consumption by optimizing pump operations.

- Preventing floods – Ensuring timely wastewater removal to protect infrastructure.

However, not all sensors perform equally well under different conditions. Float switches—while simple and cost-effective—are often unreliable in highly turbulent, greasy, or corrosive wastewater environments. Tuning fork level switches and radar level sensors, on the other hand, offer greater precision, durability, and resistance to environmental challenges.

Advanced Level Sensing Technologies for Sewage Pumps

1. Tuning Fork Level Switches: High Precision & Reliability

A tuning fork level switch operates based on the vibration frequency of a fork-shaped probe. When submerged in liquid, the vibration frequency changes, triggering a detection signal.

Key Advantages:

✔ Certified Safety Standards – High-reliability models, such as those compliant with SIL2/3 (Safety Integrity Level) certification, ensure robust performance in critical applications.

✔ High-Temperature Resistance – Some models can withstand extreme conditions, with operating temperatures up to 280°C, making them suitable for industrial wastewater systems.

✔ Corrosion-Resistant Materials – Options like Hastelloy C and stainless steel provide superior protection in highly corrosive environments.

✔ Immunity to External Disturbances – Unlike float switches, tuning fork sensors are unaffected by foam, turbulence, or vapor, ensuring stable readings.

Real-World Application:

Many industrial wastewater plants have switched to tuning fork level sensors due to the failure rate of float switches in high-grease environments. A municipal sewage treatment plant reported a 50% reduction in maintenance costs after upgrading to tuning fork technology, which eliminated false alarms caused by foam accumulation.

2. Radar Level Sensors: Non-Contact & High-Precision Monitoring

A radar level sensor uses high-frequency microwave signals to measure liquid levels without direct contact with the medium. These sensors are ideal for environments where direct exposure could cause sensor degradation or contamination.

Key Advantages:

✔ Non-Contact Measurement – Eliminates risks of sensor fouling, making it ideal for highly contaminated or sticky fluids.

✔ Extreme Environment Adaptability – Capable of operating under high pressure, high temperature, and varying densities.

✔ Bluetooth Connectivity – Some radar sensors feature Bluetooth-enabled remote monitoring, allowing for configuration and real-time data access via mobile devices.

✔ Fast Response Time & High Accuracy – Provides millimeter-level precision, even in foam-covered or turbulent liquid conditions.

Real-World Application:

A wastewater treatment facility dealing with high-foam effluent from chemical processing replaced ultrasonic sensors with radar level sensors. This switch resulted in a 90% reduction in false readings, enabling better pump automation and lowering operational costs.

Comparing Sewage Pump Level Sensor Technologies

To help decision-makers choose the right solution, the following table summarizes the key differences between float switches, tuning fork level switches, and radar level sensors:

| Feature | Float Switch | Tuning Fork Level Switch | Radar Level Sensor |

|---|---|---|---|

| Contact Type | Direct Contact | Direct Contact | Non-Contact |

| Accuracy | Low | Medium-High | High |

| Resistance to Foam | Poor | High | Very High |

| Durability | Moderate | High | Very High |

| Application Complexity | Simple Systems | Industrial & Complex Fluids | Complex, High-Precision Environments |

| Remote Monitoring | No | No | Yes (Bluetooth-enabled) |

| Best Use Cases | Basic sewage pits | Industrial wastewater, oils | Chemical & wastewater treatment |

Conclusion: Choosing the Right Sensor for Reliable Sewage Pump Systems

Selecting the most appropriate sewage pump level sensor is critical for ensuring long-term system efficiency, reducing maintenance efforts, and preventing unexpected failures.

- For standard wastewater applications, tuning fork level switches provide a balance of affordability, reliability, and robustness, making them an excellent alternative to traditional float switches.

- For high-precision monitoring in extreme environments, radar level sensors offer non-contact measurement, durability, and remote accessibility, making them ideal for industrial and chemical wastewater management.

By integrating advanced level sensing technologies into sewage pump systems, operators can reduce operational costs, increase system longevity, and improve water level management reliability.

Final Thoughts

If you are considering an upgrade from traditional float switches, exploring tuning fork level switches and radar level sensors can significantly improve wastewater management efficiency. Proper sensor selection depends on environmental conditions, fluid properties, and monitoring requirements. Investing in high-quality sensors ensures long-term performance and cost savings in industrial and municipal sewage systems.