Introduction

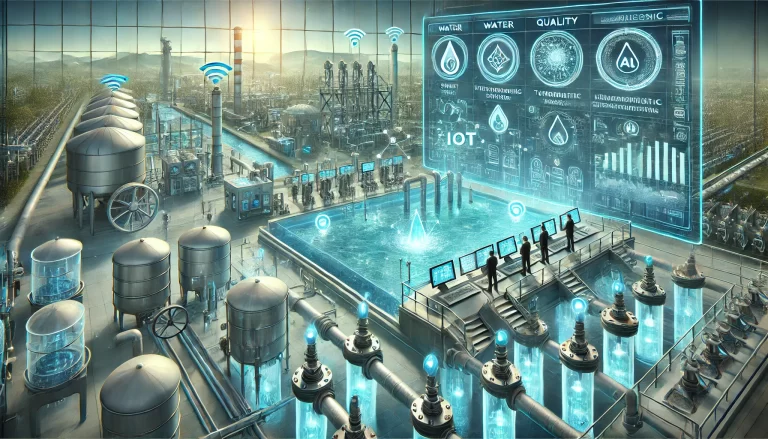

Smart Water Management (SWM) refers to the integration of modern technologies such as the Internet of Things (IoT), big data, cloud computing, and artificial intelligence (AI) to digitalize and intelligently upgrade water supply, drainage, wastewater treatment, and water resource management. The goal is to improve efficiency, reliability, and sustainability in water systems.

1. Core Components of Smart Water Management

(1) Intelligent Sensing Layer

Uses sensors, flow meters, and water quality monitoring devices to collect real-time data on water resources, water quality, pressure, and levels.

(2) Data Transmission Layer

Utilizes 5G, NB-IoT, LoRa, and other wireless communication technologies to transmit monitoring data to data centers.

(3) Data Processing and Analysis Layer

Employs cloud computing, big data analytics, and AI to process large-scale data for smart scheduling, anomaly detection, and predictive analysis.

(4) Business Application Layer

Includes smart water management platforms, intelligent scheduling systems, early warning systems, remote control, and customer services.

2. Key Applications of Smart Water Management

(1) Smart Water Supply

Remote water quality monitoring, optimized water supply scheduling, leakage reduction, and efficiency improvement.

(2) Smart Drainage

Real-time monitoring of pipeline networks, intelligent pump station control, and flood risk prevention.

(3) Smart Wastewater Treatment

Continuous monitoring of wastewater treatment plants, optimizing treatment processes, and improving discharge quality.

(4) Water Resource Management

Smart monitoring and forecasting for optimized water resource allocation and conservation strategies.

(5) Customer Services

Smart meters, online billing, and water usage analytics for improved user experience.

3. Advantages of Smart Water Management

Enhances operational efficiency and reduces labor costs.

Detects pipeline leaks in real time, reducing water loss.

Ensures water quality safety and prevents pollution incidents.

Provides accurate forecasts for optimized scheduling and water supply reliability.

Supports government decision-making for sustainable water resource management.

Smart water management is the future of the water industry, especially in the face of urbanization and climate change challenges, making its significance increasingly prominent.

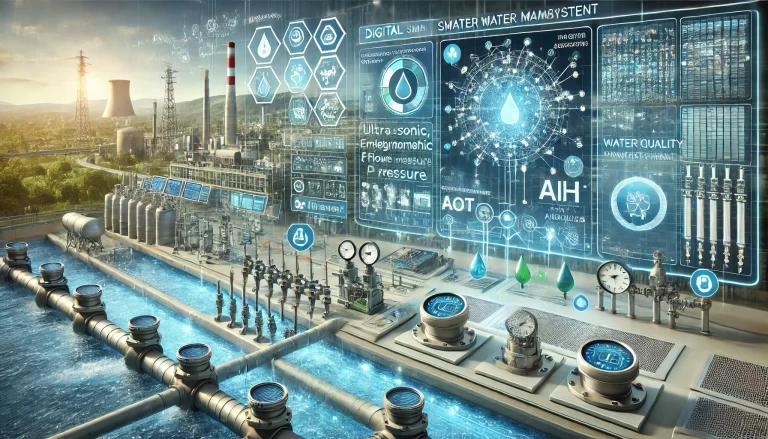

4. Types and Applications of Process Instruments

Process instruments in smart water management systems can be categorized based on their measurement functions:

(1) Flow Measurement Instruments

Ultrasonic Flow Meters – Ideal for large-diameter pipelines and non-contact measurement.

Electromagnetic Flow Meters – Widely used in potable water, wastewater, and industrial water applications.

Turbine Flow Meters – Suitable for clean water measurement.

Orifice Flow Meters – Used for high-precision flow monitoring.

📌 Application Scenarios:

Real-time monitoring of water distribution networks to optimize supply and reduce losses.

Flow measurement in wastewater treatment plants.

Industrial wastewater discharge monitoring.

Leakage detection and efficiency improvement.

(2) Water Quality Analysis Instruments

pH Meters – Measure the acidity and alkalinity of water.

Dissolved Oxygen Analyzers – Assess oxygen levels in water.

Turbidity Meters – Monitor water clarity.

Conductivity Meters – Detect the electrical conductivity of water, indirectly reflecting its purity.

COD/BOD Monitors – Measure chemical and biological oxygen demand in wastewater treatment.

Ammonia Nitrogen/Total Phosphorus/Total Nitrogen Analyzers – Monitor pollutant concentrations.

📌 Application Scenarios:

Real-time drinking water quality monitoring to ensure safety.

Compliance monitoring for wastewater discharge.

Continuous monitoring of lakes and rivers to detect pollution.

(3) Pressure Measurement Instruments

Pressure Sensors – Monitor pressure levels in water distribution systems.

Differential Pressure Transmitters – Measure pressure differences in filtration systems and pump stations.

📌 Application Scenarios:

Pressure monitoring to optimize water distribution.

Pump station operational efficiency monitoring.

Leak detection and pipeline performance evaluation.

(4) Level Measurement Instruments

Ultrasonic Level Meters – Non-contact measurement for liquid levels.

Radar Level Meters – Suitable for reservoirs and sewage treatment tanks.

Float Level Meters – Used in water towers and tanks.

📌 Application Scenarios:

Monitoring water levels in reservoirs, clear water tanks, and pumping stations.

Wastewater treatment sedimentation and aeration tank level monitoring.

Flood prevention and drainage system level detection.

(5) Temperature Measurement Instruments

Temperature Sensors – Monitor temperature variations in water processes.

Infrared Thermometers – Non-contact remote temperature monitoring.

📌 Application Scenarios:

Pipeline temperature monitoring to prevent freezing in winter.

Optimization of wastewater treatment processes based on microbial activity.

Industrial wastewater discharge temperature monitoring.

5. The Role of Process Instruments in Smart Water Management

✅ Real-time Data Acquisition: Sensors and instruments collect real-time data on water quality, flow, pressure, and temperature, enabling a digitalized water management system.

✅ Remote Monitoring and Automation: Integrated with SCADA (Supervisory Control and Data Acquisition) systems, process instruments facilitate remote monitoring and automated control.

✅ Smart Alerts and Fault Detection: AI-driven data analysis helps identify anomalies such as pipeline leaks or water quality deviations, triggering timely alerts.

✅ Energy and Cost Optimization: By optimizing pump and valve operations, process instruments enhance water resource efficiency and reduce operational costs.

✅ Data-Driven Decision Support: Big data analytics improve water network operation, enhance demand forecasting, and support regulatory compliance.

6. Future Trends in Process Instrumentation for Smart Water Management

Advanced High-Precision Multi-Parameter Sensors – Improved measurement accuracy and multi-parameter monitoring.

Wireless and Low-Power Technologies – Deployment of IoT-based low-power transmission networks for cost-effective operations.

AI-Driven Predictive Analytics – AI models to predict pipeline failures, optimize water distribution, and enhance efficiency.

Edge Computing Implementation – Real-time data processing at the sensor level for faster response and reduced cloud computing costs.

Conclusion

Process instruments serve as the foundation of smart water management by providing real-time monitoring, automated control, and data-driven decision-making capabilities. The continuous evolution of sensor technology, IoT communication, and AI-powered analytics will further enhance the efficiency, sustainability, and resilience of water systems in the future.