Introduction

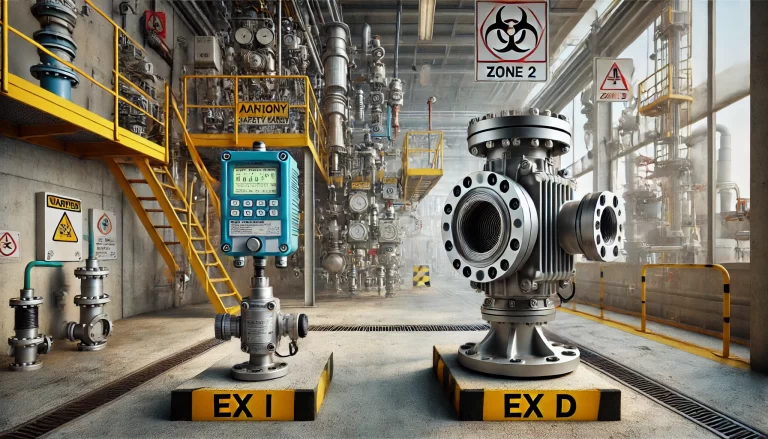

When selecting instruments for hazardous areas classified as Zone 2, it is crucial to consider safety standards and the nature of the installation. Two common protection methods for electrical instruments in hazardous environments are intrinsic safety (Ex i) and explosion-proof (Ex d). Understanding their principles, advantages, and limitations helps in making an informed choice.

Understanding Zone 2 Hazardous Areas

Zone 2 is defined by the IEC and ATEX classification as an area where explosive gas atmospheres are unlikely to occur in normal operation but, if they do occur, will persist for only a short duration. This makes safety measures essential but allows for more flexible equipment choices compared to Zone 1 or Zone 0.

Intrinsic Safety (Ex i) Explained

Intrinsic safety (Ex i) is a protection concept that limits the electrical energy in the instrument to prevent the formation of sparks or excessive heat that could ignite an explosive atmosphere.

Key Features of Intrinsically Safe Instruments:

Operate with low power levels, ensuring no ignition source is generated.

Require the use of safety barriers or isolators to limit voltage and current.

Commonly used for measuring and control devices, such as sensors, pressure transmitters, and flow meters.

Allow maintenance and replacement without shutting down the system.

Advantages of Intrinsic Safety (Ex i):

High Safety Level: Reduces the risk of ignition due to limited energy supply.

Ease of Maintenance: Instruments can be serviced and replaced without de-energizing the area.

Lightweight and Compact: Requires less heavy-duty enclosures compared to Ex d devices.

Lower Installation Costs: Requires less rigid conduit systems, reducing material and labor costs.

Limitations of Intrinsic Safety:

Limited Power: Cannot be used for high-power applications like motors or solenoid valves.

Additional Safety Barriers Required: Extra components like isolators and barriers increase system complexity.

Explosion-Proof (Ex d) Protection Explained

Explosion-proof or flameproof (Ex d) protection relies on enclosing electrical components within a robust, flame-resistant enclosure. In case of an internal explosion, the enclosure prevents flames or hot gases from igniting the surrounding hazardous atmosphere.

Key Features of Explosion-Proof Instruments:

The enclosure must be strong enough to contain an explosion.

Typically used for higher power equipment such as actuators, control switches, and large solenoid valves.

The instrument must be fully enclosed, and maintenance requires complete power shutdown.

Advantages of Explosion-Proof (Ex d):

Higher Power Capability: Suitable for equipment with higher voltage and current requirements.

No Need for External Safety Barriers: Unlike Ex i systems, no additional safety components are required.

Durability: Withstands harsh environmental conditions and mechanical impacts.

Limitations of Explosion-Proof Protection:

Bulky and Heavy: Requires thick-walled enclosures made of strong materials.

Difficult Maintenance: The instrument must be fully de-energized before opening the enclosure.

Higher Installation Costs: Requires rigid conduit wiring systems, increasing complexity and cost.

Choosing the Right Protection Method for Zone 2

When selecting between intrinsic safety (Ex i) and explosion-proof (Ex d) for Zone 2 applications, consider the following factors:

| Factor | Intrinsic Safety (Ex i) | Explosion-Proof (Ex d) |

|---|---|---|

| Power Requirements | Suitable for low-power devices | Suitable for high-power equipment |

| Maintenance | Can be serviced live | Must be powered down for maintenance |

| Size & Weight | Compact and lightweight | Heavy enclosures required |

| Installation Cost | Lower cost (simple wiring) | Higher cost (rigid conduits) |

| Application Examples | Sensors, transmitters, small control devices | Motors, actuators, solenoid valves |

Recommendations for Zone 2 Applications

For measurement and control instruments (e.g., pressure, temperature, and flow sensors) → Intrinsic Safety (Ex i) is preferable due to ease of maintenance and lower cost.

For high-power equipment (e.g., electric motors, large valves, actuators) → Explosion-Proof (Ex d) is recommended as it can handle higher power loads safely.

If existing infrastructure already supports intrinsic safety barriers → Stick to Ex i to optimize costs and compatibility.

If maintenance in a hazardous environment is a concern → Ex i is better, as devices can be replaced without a shutdown.

If mechanical durability is a primary concern (e.g., outdoor or heavy-duty applications) → Ex d is a more robust choice.

Conclusion

Both intrinsic safety (Ex i) and explosion-proof (Ex d) are viable solutions for Zone 2 hazardous areas, but their selection depends on power requirements, installation constraints, and maintenance considerations. While Ex i is better for low-power, easily maintainable systems, Ex d is necessary for high-power, durable applications. Evaluating the specific operational requirements will ensure a safe and efficient instrumentation choice in hazardous environments.