Selecting the right transmitter for an application is a crucial process that ensures accurate measurements, reliable performance, and cost-effectiveness. This article provides a comprehensive guide on transmitter selection, detailing key steps, factors to consider, and common pitfalls to avoid.

Step 1: Define Measurement Requirements

1.1 Identify the Measurement Parameter

The first step in selecting a transmitter is to define the physical quantity that needs to be measured. Transmitters are designed to measure different parameters, including:

Pressure (e.g., pressure transmitters for gas and liquid systems)

Temperature (e.g., RTD or thermocouple-based temperature transmitters)

Flow rate (e.g., differential pressure, ultrasonic, or electromagnetic flow transmitters)

Liquid level (e.g., radar, ultrasonic, or hydrostatic level transmitters)

Choosing the wrong transmitter type for a specific measurement parameter can result in incorrect data and potential process failures.

1.2 Understand the Characteristics of the Medium

The properties of the measured medium significantly impact transmitter selection. Consider the following:

Corrosive or aggressive substances: If measuring highly corrosive chemicals (e.g., sulfuric acid), the transmitter must be made of corrosion-resistant materials like PTFE, Hastelloy, or titanium.

Viscosity and particle content: High-viscosity fluids or those containing solid particles may require non-contact measurement techniques, such as ultrasonic or radar.

Electrical conductivity: Certain measurement methods, like electromagnetic flow measurement, depend on the medium’s conductivity.

1.3 Determine the Measurement Range

The chosen transmitter must be capable of measuring within the expected operating range with a margin of safety. For example, if a pipeline’s pressure fluctuates between 0-10 MPa, the transmitter should have a range slightly beyond this to prevent overloading or damage.

1.4 Define Accuracy Requirements

The accuracy requirement depends on the application:

High-precision applications (e.g., critical chemical dosing): ±0.1% or better

General monitoring purposes: ±0.5% may be acceptable

Non-critical measurements (e.g., environmental monitoring): ±1% may suffice

Failing to define accuracy requirements properly can lead to unnecessary costs or inadequate performance.

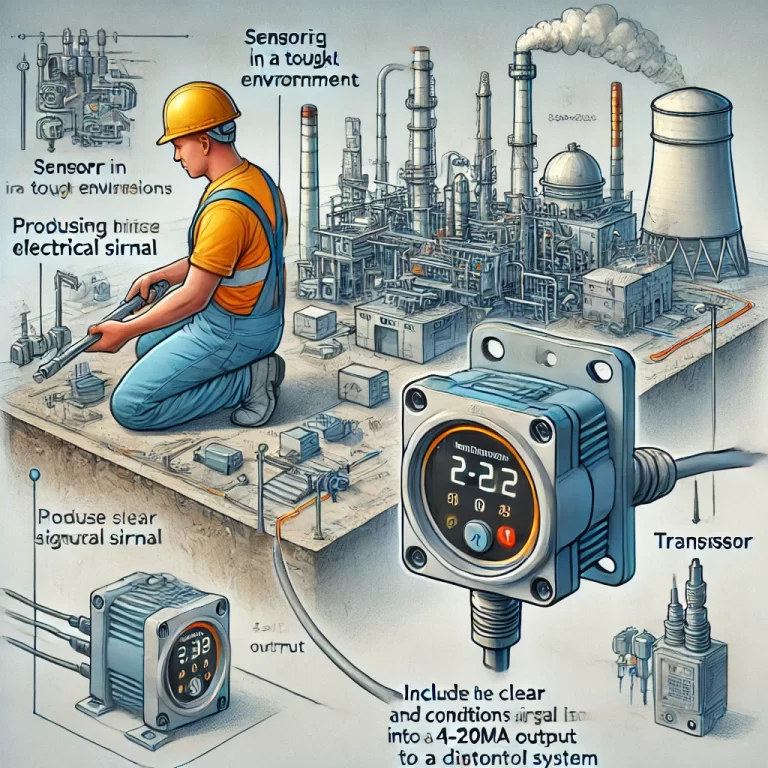

1.5 Choose an Appropriate Output Signal

Transmitters typically provide various signal outputs, including:

Analog signals: 4-20 mA (widely used for long-distance transmission and noise immunity)

Voltage signals: 0-10V (less common but useful in certain applications)

Digital communication protocols: HART, Profibus, Modbus, and Foundation Fieldbus for smart measurement and process control integration

Choosing an incompatible signal output can complicate system integration and lead to additional conversion costs.

Step 2: Assess Environmental Conditions

2.1 Temperature and Humidity

If the transmitter operates in extreme temperatures, select one with appropriate temperature compensation.

High-humidity environments require a transmitter with a high IP (Ingress Protection) rating, such as IP67 or higher, to prevent moisture ingress.

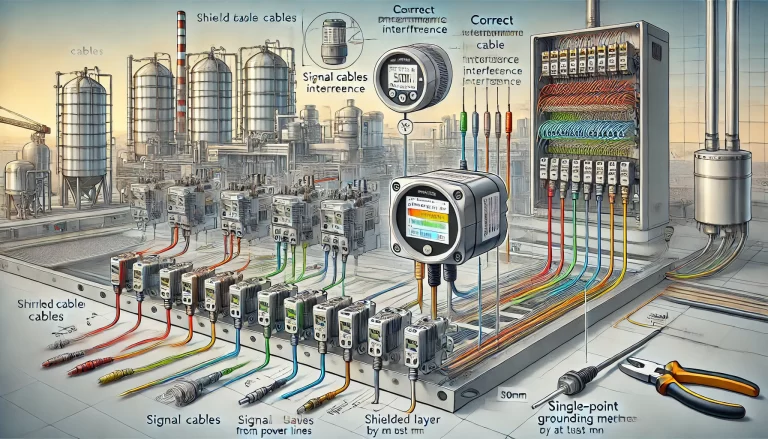

2.2 Electromagnetic Interference (EMI) Considerations

Install transmitters away from strong electromagnetic sources like variable frequency drives (VFDs), large motors, and high-frequency equipment.

Select EMC (Electromagnetic Compatibility)-certified devices to minimize signal distortion.

2.3 Explosion-Proof Requirements

In hazardous environments such as chemical plants, oil refineries, or mining operations, select intrinsically safe (IS) or explosion-proof (Ex) rated transmitters.

2.4 Space and Installation Constraints

In compact spaces, opt for small, easy-to-install transmitters.

Ensure the mounting style (e.g., flange, threaded, or clamp-on) is suitable for the application.

Step 3: Evaluate Reliability and Maintainability

3.1 Brand Reputation and Product Quality

Select manufacturers with a strong track record for reliability, such as Siemens, Emerson, Yokogawa, and Honeywell.

Check for ISO9001, CE, UL, and industry-specific certifications.

3.2 Maintenance Considerations

Choose transmitters with self-diagnostic and fault alarm features.

Ensure easy access to spare parts and support.

Modular designs simplify maintenance and part replacements.

Step 4: Perform Cost Analysis

4.1 Initial Procurement Costs

While cost is a factor, do not compromise on quality. A low-cost transmitter may lead to higher long-term expenses due to frequent replacements and maintenance.

4.2 Operational and Maintenance Costs

Consider power consumption, calibration frequency, and spare part availability.

Smart transmitters may have higher upfront costs but can reduce overall maintenance expenses.

4.3 Lifecycle Cost Analysis

Factor in installation, training, calibration, repair, and eventual decommissioning costs.

A higher-quality transmitter may have a lower total cost of ownership (TCO) than a cheaper alternative.

Step 5: Conduct Comprehensive Evaluation and Final Selection

5.1 Compare Technical Performance

Evaluate key performance metrics such as accuracy, stability, response time, and signal integrity.

Review test reports or conduct pilot testing if necessary.

5.2 Assess Supplier Support and After-Sales Service

Ensure the supplier offers technical support, training, fast repair services, and spare part availability.

5.3 Avoid Common Selection Mistakes

Ignoring environmental conditions: Leads to premature failure

Overestimating accuracy needs: Increases costs unnecessarily

Focusing only on price: Leads to poor reliability and higher operational costs

Conclusion

Selecting the right transmitter involves more than just technical specifications; it requires careful evaluation of environmental factors, maintenance needs, cost implications, and supplier reliability. By following this structured approach, industries can ensure they invest in a solution that provides long-term accuracy, reliability, and cost-effectiveness.

If feasible, companies should conduct on-site trials or request demo units to validate the suitability of their chosen transmitters before full-scale implementation.