Introduction

O-rings, circular cross-section elastic sealing elements, are widely used in both static and dynamic sealing applications due to their simple structure, excellent sealing performance, and cost-effectiveness. In chemical instrumentation, O-rings must endure extreme working conditions, including high temperatures, high pressures, and corrosive media. Therefore, their material selection, design, and installation require a high level of expertise. This article systematically explores the application of O-rings in chemical instrumentation, focusing on their working principles, material properties, selection criteria, standard specifications, and future development trends.

I. Working Principles of O-Rings

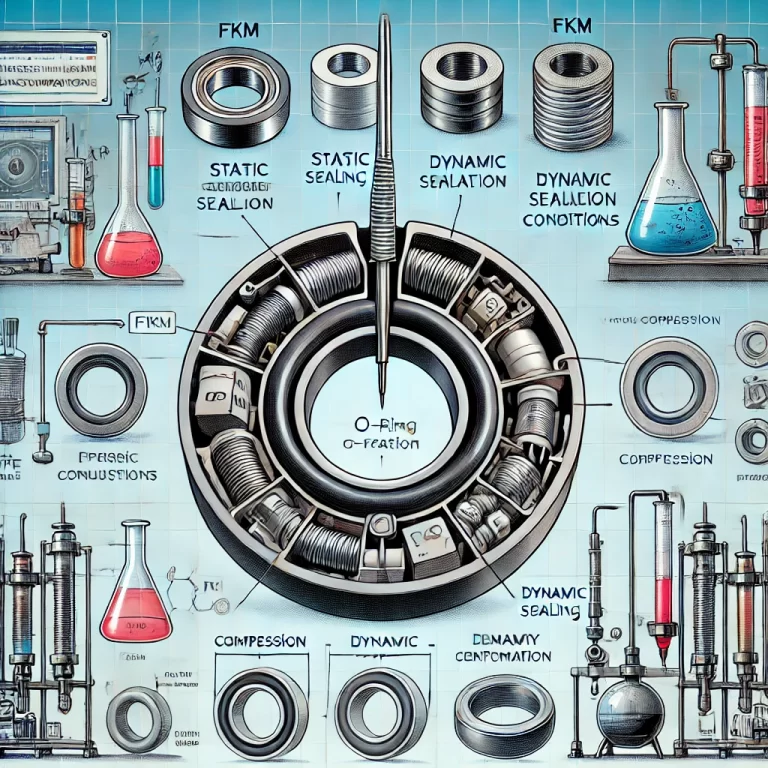

1. Sealing Mechanism

The sealing function of an O-ring is based on elastic deformation, which creates contact pressure. When an O-ring is compressed in a groove, its cross-section deforms, generating an initial sealing force. Under working conditions, the medium pressure further compresses the O-ring against the sealing surface, enhancing the sealing effect.

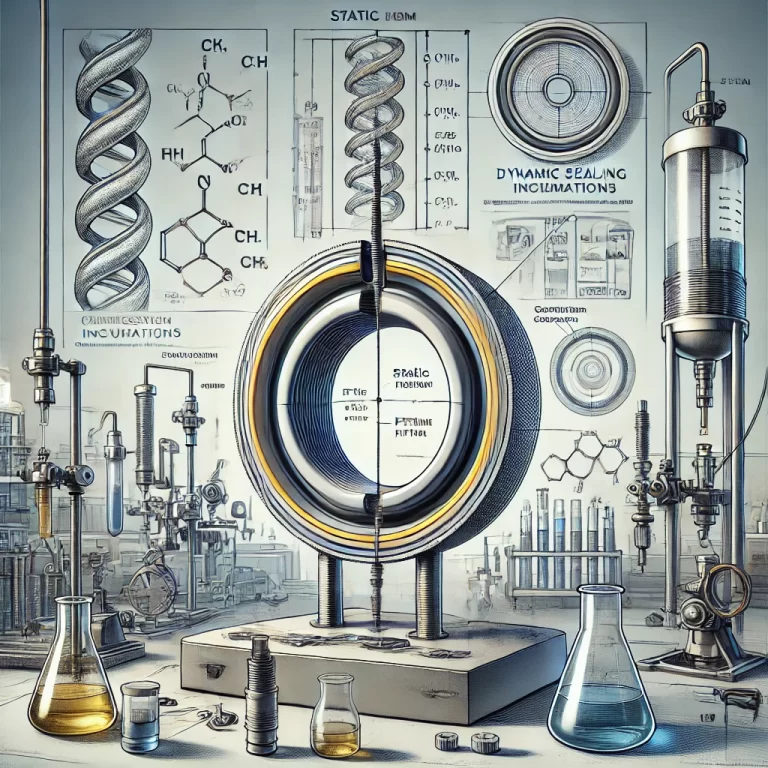

2. Static vs. Dynamic Sealing

Static Sealing: Achieved through a compression ratio (typically 10%-30%), ensuring continuous contact pressure. Common in flanges, valves, and pipe joints.

Dynamic Sealing: Requires a lower compression ratio (~10%) to balance friction and wear resistance. Used in reciprocating pistons and rotating shafts.

3. Failure Mechanisms

Several factors can lead to O-ring failure:

Excessive Compression: Leads to permanent deformation and loss of elasticity.

Under-Compression: Causes leakage due to inadequate sealing pressure.

Overstretching: Weakens sealing effectiveness and increases stress concentration.

Chemical Degradation: Exposure to incompatible chemicals results in swelling, hardening, or cracking.

Thermal Degradation: High temperatures accelerate aging and reduce elasticity.

II. Material Selection for O-Rings in Chemical Instrumentation

Chemical environments require O-rings with high resistance to corrosion, temperature extremes, and mechanical wear. Below are common materials and their characteristics:

| Material | Advantages | Disadvantages | Suitable Applications |

|---|---|---|---|

| Fluorocarbon Rubber (FKM/FPM) | High-temperature resistance (-20°C~250°C), excellent chemical resistance | Expensive, reduced elasticity at low temperatures | Corrosive media in reactors, pumps, and valves |

| Polytetrafluoroethylene (PTFE) | Chemically inert, low friction, broad chemical compatibility | Poor elasticity, requires backup springs | High-purity or aggressive chemical environments, analytical instruments |

| Perfluoroelastomer (FFKM) | Extreme chemical and thermal resistance (-30°C~320°C) | Very high cost | Semiconductor manufacturing, extreme chemical environments |

| Polyurethane (PU/CPU) | High wear resistance, withstands up to 32MPa pressure | Limited temperature resistance (max 120°C) | Hydraulic systems in chemical machinery |

Selection Priority: FKM > PTFE > FFKM > PU (depending on cost and working conditions).

III. Key Considerations for O-Ring Selection in Chemical Instrumentation

1. Operating Conditions

Chemical Compatibility: The O-ring material must be compatible with the medium (e.g., FKM for strong acids, EPDM unsuitable for oils).

Temperature Range: High-temperature applications require FKM or FFKM, while low-temperature environments may use silicone rubber.

Pressure Requirements: For pressures >63Bar, materials with a hardness of 90 Shore A are recommended; for pressures ≤63Bar, 70 Shore A is sufficient.

2. Installation Design

Groove Dimensions: Follow DIN 3771 standards.

Static sealing: Surface roughness ≤25μm.

Dynamic sealing: Surface roughness ≤4μm (piston face).

Compression Ratio:

Static sealing: 15%-30%.

Dynamic sealing: <10% to prevent excessive wear.

3. Economic Considerations & Service Life

Higher initial cost (e.g., FKM) may reduce maintenance costs by extending service life.

PTFE is suitable for single-use, high-purity applications such as pharmaceutical and food industries.

IV. O-Ring Standards and Specifications for Chemical Instrumentation

1. Standardized Sizing Systems

International Standards: AS568 (US), JIS B2401 (Japan), DIN 37716 (Europe)

Chinese Standards: GB/T 3452.1 (dimensions), GB/T 3452.2 (appearance), HG/T 2579 (material properties)

2. Typical Specification Parameters

Cross-section diameter (d2): 1.5mm

10mm (common: 2.4mm5.7mm for chemical instruments)Inner diameter (d1): Custom-sized based on interface dimensions, with strict tolerance control (e.g., Φ18mm ± 0.1mm)

3. Certification Requirements

FDA (Food-Grade Compliance): Required for pharmaceutical and food-processing applications.

NORSOK (Oil & Gas Industry Compliance): Required for petrochemical applications.

V. Case Studies & Practical Applications

Case 1: Chemical Reactor O-Ring Failure Due to Incorrect Material Selection

A petrochemical plant experienced frequent leaks in its reactor sealing system. The original nitrile rubber (NBR) O-rings failed due to chemical degradation caused by exposure to aggressive acids. After switching to FKM O-rings, the service life increased from 3 months to over 2 years, significantly reducing downtime and maintenance costs.

Case 2: PTFE O-Rings in High-Purity Chemical Analysis Equipment

In a laboratory using an analytical instrument for high-purity chemical detection, contamination issues were traced back to rubber O-rings. Replacing them with PTFE O-rings eliminated contamination, ensuring more accurate readings while extending the equipment’s lifespan.

VI. Future Trends in O-Ring Technology

1. Material Innovations

Development of ultra-high-temperature resistant perfluoroelastomers (>300°C).

Biocompatible O-rings for pharmaceutical and medical applications.

2. Intelligent Design

Finite Element Analysis (FEA) modeling to optimize groove structure and compression rates.

Wear-resistant coatings to improve longevity in dynamic sealing applications.

3. Environmental Considerations

Adoption of silicone oil-free lubricants and recyclable rubber materials to meet sustainability requirements.

Conclusion

O-rings play a crucial role in chemical instrumentation, ensuring reliable sealing performance under challenging conditions. Proper material selection, precise installation, and adherence to industry standards significantly enhance system reliability and longevity. With ongoing advancements in materials and intelligent design, the future of O-ring technology will continue to evolve, improving efficiency and reducing maintenance costs in industrial applications.