Introduction

In modern industrial automation, Configuration and Human-Machine Interface (HMI) are two fundamental concepts that play a critical role in intelligent control systems. While these concepts might seem straightforward, their functionalities are profound and indispensable. This article provides an in-depth exploration of these concepts, discussing their definitions, functions, key technical features, and widespread applications in industrial automation.

What is Configuration in Industrial Automation?

Configuration refers to the process of setting up and customizing an industrial automation system using specialized configuration software tools. Essentially, it involves using software to “construct” an automation control system. Engineers employ graphical user interfaces (GUIs) or programming methods to configure equipment parameters, define data flow, and design operational interfaces to enable the rapid development and deployment of industrial automation systems.

For example, in an industrial production line, engineers use configuration software to set operational parameters for devices such as:

Sensor data acquisition frequency

Speed of automation equipment

Rules for data transmission and interaction between different devices

Configuration software also allows the design of monitoring interfaces and the setup of alarm conditions and response strategies. The key advantages of configuration technology include flexibility and high customization capability. Whether for production equipment, sensors, or entire system workflows, configuration software can be tailored to meet specific industrial requirements.

Core Elements of Configuration:

Graphical programming – Simplifies complex control logic through a visual representation.

Control logic design – Defines system behavior based on predefined conditions and rules.

Communication interface setup – Ensures seamless interaction between various industrial devices using protocols such as Modbus, OPC UA, and MQTT.

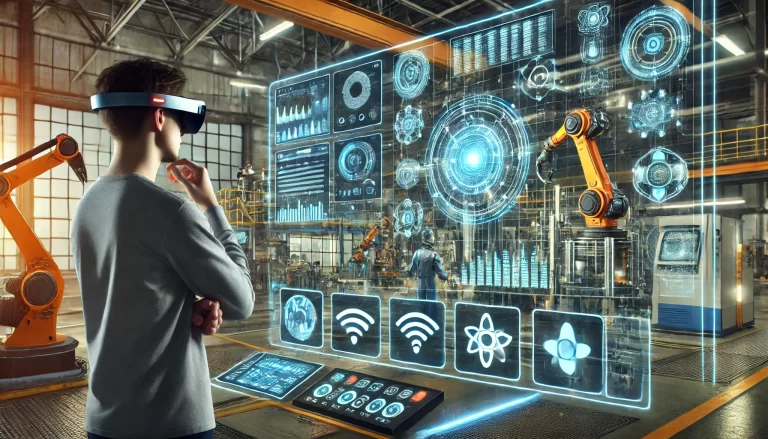

What is HMI (Human-Machine Interface)?

The Human-Machine Interface (HMI) acts as a bridge between humans and industrial automation systems. The primary function of HMI is to provide real-time visualization of system operations and enable intuitive control of industrial equipment. HMI systems can come in various forms, including:

Touchscreen panels used in factories for real-time monitoring

Computer-based HMI software for centralized control in industrial plants

Mobile applications that allow remote system management via smartphones or tablets

Key Functions of HMI:

Real-time Monitoring – Operators can view the status of industrial processes instantly.

Control and Interaction – Users can issue commands to start, stop, or adjust system operations.

Alarm and Notification Management – Alerts users to system faults or performance anomalies.

Data Visualization – Provides graphical representations of system trends for better decision-making.

For instance, in a smart transportation system, subway control center staff utilize HMI interfaces to:

Monitor train operations in real time

Adjust train scheduling

Initiate emergency procedures, such as stopping a train if an issue is detected

A well-designed HMI should be intuitive, responsive, and highly stable to ensure seamless industrial operations.

Relationship Between Configuration and HMI

Although Configuration and HMI serve different functions, they complement each other in industrial automation.

Key Differences:

| Feature | Configuration | HMI |

|---|---|---|

| Purpose | Defines system parameters and automation logic | Enables user interaction with the system |

| Users | Automation engineers, technical personnel | Operators, system users |

| Scope | System setup, device configurations, workflow design | Real-time control, monitoring, and adjustments |

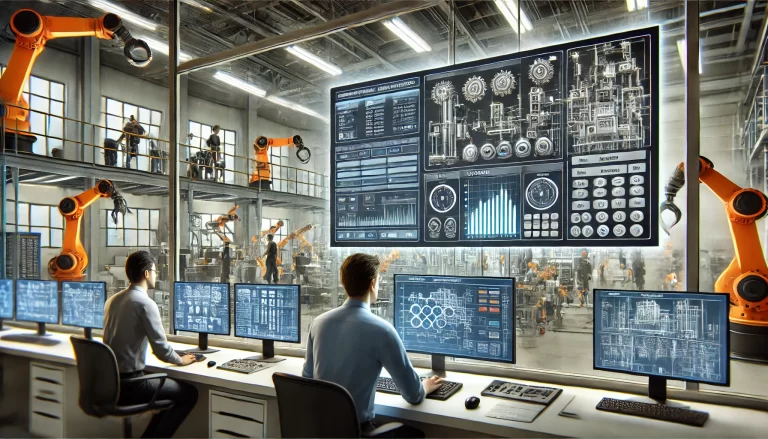

Collaboration Between Configuration and HMI:

Configuration software is used to build the automation system framework, set device parameters, and design workflows.

HMI software presents a user-friendly interface, allowing operators to monitor and control configured systems.

For example, in a manufacturing plant:

Engineers configure robotic welding parameters using configuration tools.

Operators use HMI screens to supervise welding operations and make necessary adjustments.

Joint Applications of Configuration and HMI

Configuration and HMI are frequently used together to enhance industrial automation. Below are some key application areas:

1. Industrial Production Monitoring

Configuration: Engineers set device parameters and monitoring rules.

HMI: Operators observe system performance, adjust parameters, and troubleshoot problems.

Example: In an automobile factory, configuration software defines robotic arm movements, while HMI interfaces allow operators to monitor welding precision and quality.

2. Energy Management Systems

Configuration: Configures data acquisition from power systems, such as voltage, current, and power output.

HMI: Displays real-time power consumption trends and enables operators to optimize energy usage.

Example: In a power grid monitoring system, configuration tools manage substation equipment parameters, while HMI systems provide real-time visualization and control.

3. Smart Traffic Management

Configuration: Defines parameters for train schedules and traffic signals.

HMI: Allows operators to monitor train speeds, adjust signals, and optimize traffic flow.

Example: In subway control systems, configuration software sets up train dispatch rules, while HMI screens show train locations and schedules.

4. Medical Equipment Control

Configuration: Sets operational parameters for medical devices such as CT scanners or robotic surgery equipment.

HMI: Enables healthcare professionals to interact with devices and monitor patient data.

Example: A robotic surgery system uses configuration software to program robotic arm movements, while surgeons operate through an HMI interface.

Future Trends and Technological Advancements

With the rapid evolution of Industry 4.0 and smart manufacturing, configuration and HMI technologies are advancing in several ways:

Integration with Industrial Internet of Things (IIoT)

Seamless cloud connectivity for remote monitoring and predictive maintenance.

AI-powered HMI Systems

Enhanced automation decision-making through machine learning and AI algorithms.

Low-Code/No-Code Configuration Tools

Simplifies automation system setup, reducing dependency on programming expertise.

Digital Twin Technology

Creates virtual simulations of physical systems for testing and optimization before deployment.

Improved Cybersecurity Measures

Advanced encryption and authentication protocols to protect industrial systems from cyber threats.

Conclusion

Configuration and HMI are essential components of modern industrial automation. Configuration enables system customization and optimization, while HMI provides an intuitive interface for system interaction. Their synergy enhances industrial efficiency, flexibility, and usability. As smart automation technologies continue to evolve, the integration of Configuration and HMI with AI, IIoT, and cybersecurity solutions will further transform industrial operations.

By leveraging these technologies effectively, industries can achieve higher productivity, improved system reliability, and a more user-friendly operational experience, paving the way for the future of intelligent manufacturing and automation.