Interference

Proper wiring of temperature transmitters is essential to ensure accurate signal transmission and minimize interference. This article outlines the best practices for selecting cables, laying out wiring, grounding, and other key considerations to avoid signal disruptions and improve system reliability.

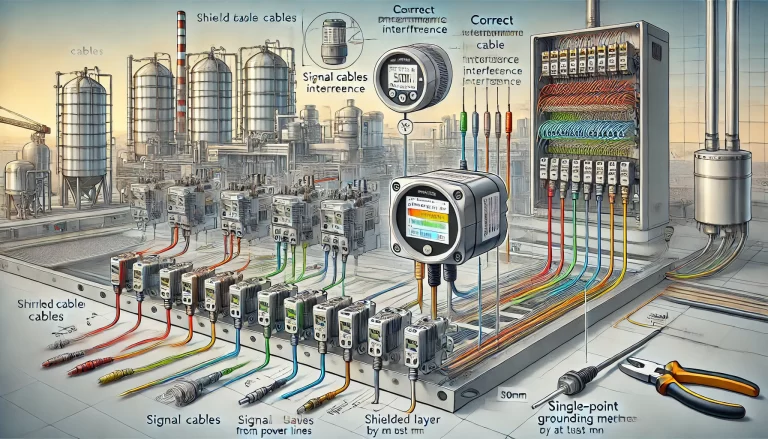

1. Cable Selection

Choosing the right type of cable plays a crucial role in minimizing electromagnetic interference (EMI) and ensuring the integrity of transmitted signals. The following aspects should be considered:

1.1 Use Shielded Cables

Always select cables with a metallic shielding layer, such as copper braid shielded cables or aluminum foil shielded cables.

The shielding layer effectively blocks external electromagnetic interference and prevents internal signal leakage that could affect nearby devices.

For environments with high interference levels or applications requiring high signal accuracy, double-shielded cables should be used.

1.2 Suitable Cable Material and Specifications

Choose copper-core cables for their excellent conductivity and resistance to interference.

The cable’s gauge (thickness) should match the required transmission distance and signal strength to reduce attenuation.

For long-distance transmission or high-impedance signals, opt for cables with a larger cross-sectional area to minimize signal loss.

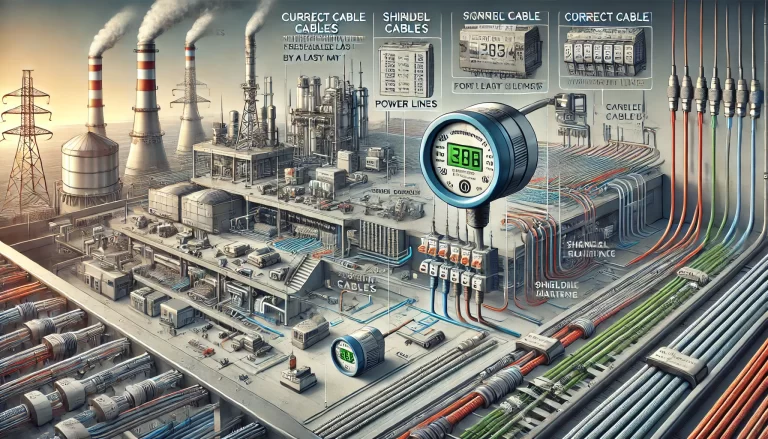

2. Cable Routing Guidelines

Correct cable layout is critical to preventing signal degradation caused by electromagnetic interference. Follow these guidelines:

2.1 Maintain Distance from Interference Sources

Signal cables should be routed away from strong electrical sources, including power lines, large motors, transformers, and variable frequency drives (VFDs).

When running parallel to power cables, maintain a minimum separation distance of 300 mm (12 inches).

For high-frequency interference sources like inverters and VFDs, maintain a minimum distance of 1 meter (3.3 feet).

If proximity to an interference source is unavoidable, use perpendicular crossing instead of parallel routing and apply additional shielding protection at the crossover points.

2.2 Avoid Parallel Routing

Minimize the length of signal cables running parallel to other power cables or high-interference lines.

If parallel routing cannot be avoided, maintain proper separation and encase the signal cables in metal conduits or shielded cable trays.

When sharing a cable tray with power cables, use a metallic partition to separate signal cables from high-voltage lines.

2.3 Protect Cables from Harsh Environments

Avoid routing cables through areas with excessive heat, moisture, dust, or corrosive gases.

If exposure is unavoidable, use cables with protective insulation resistant to high temperatures, humidity, or chemical corrosion.

Consider enclosing cables in conduits or adding protective sheathing in extreme conditions.

2.4 Implement Layered Routing in Cable Trays

Within cable trays or raceways, arrange different types of cables in separate layers.

Signal cables for temperature transmitters should be installed in their own dedicated layer.

Avoid mixing them with power cables and control cables to reduce electromagnetic coupling and crosstalk.

3. Grounding Standards

Proper grounding of the shielded cables is essential to dissipate interference and prevent ground loops. The following best practices should be followed:

3.1 Single-Point Grounding for Shielded Cables

The shielding layer of the cable should be grounded at only one end, either at the temperature transmitter or the receiving device.

Multi-point grounding should be avoided, as it can create ground loops that introduce unwanted noise and voltage differences.

The grounding point should be connected to a high-quality grounding system with a resistance of less than 4Ω.

3.2 Ensure Reliable Grounding Connections

Grounding terminals should be securely connected using welding or crimping methods to ensure strong and stable contact.

Grounding conductors should have a minimum cross-sectional area of 4mm² to handle potential interference currents safely.

3.3 Independent Grounding for Temperature Transmitters

Whenever possible, temperature transmitters should have a dedicated ground point.

Avoid sharing grounding points with large current-carrying equipment to prevent interference from external noise sources.

If feasible, install a separate grounding rod specifically for the temperature transmitter system.

4. Additional Considerations

To further enhance signal integrity and prevent interference, the following measures should be implemented:

4.1 Minimize Cable Joints and Branches

Use continuous cables without unnecessary joints to minimize signal degradation and connection resistance.

If a joint is unavoidable, use professional-grade cable connectors and ensure that the shield continuity is properly maintained.

4.2 Clear Cable Identification

Label both ends and intermediate sections of cables clearly with source, destination, and purpose.

Proper identification prevents wiring errors during maintenance and reduces the risk of interference due to miswiring.

4.3 Regular Inspection and Maintenance

Periodically inspect cable insulation for damage, corrosion, or wear that could compromise signal transmission.

Ensure that grounding connections remain intact and free of oxidation, as poor grounding can lead to increased noise levels.

Check for loose cable connections and tighten them if necessary to maintain stable signal integrity.

5. Best Practice Summary

To ensure a robust and interference-free wiring setup for temperature transmitters, follow these key recommendations:

✔ Use shielded cables to protect against electromagnetic interference. ✔ Keep signal cables away from power lines and high-interference equipment. ✔ Route cables in metal conduits or shielded trays to minimize interference. ✔ Adopt a single-point grounding method for shielding layers. ✔ Label cables clearly for easy identification and maintenance. ✔ Perform routine inspections to detect and resolve potential issues early.

By adhering to these best practices, industries can significantly reduce signal disruptions, improve measurement accuracy, and enhance the overall reliability of temperature monitoring systems.