In many industrial applications, various non-electrical physical quantities such as temperature, humidity, pressure, speed, and angle need to be measured. A transmitter is the primary device used to convert these physical quantities into electrical signals for monitoring and control purposes. The most widely used method in industry to transmit analog signals is via a 4-20mA current loop.

The use of a current signal for transmission is advantageous because it is less prone to interference. Additionally, the current loop’s impedance is effectively infinite, meaning that the resistance of the wiring does not impact the accuracy of the measurement. Furthermore, current signals can be transmitted over several hundred meters using standard twisted-pair wiring without any loss of signal integrity. The upper limit of 20mA is typically chosen because, in explosion-proof environments, the energy released by a 20mA current is insufficient to cause a spark capable of igniting flammable gases.

However, in certain situations, a pressure transmitter output may exceed 20mA, which can indicate a fault in the system. Below are the key steps to diagnose and address this issue:

1. Check the Power Supply Voltage

The first step is to ensure the power supply to the transmitter is functioning properly. If the supply voltage falls below the specified minimum (usually 12V DC for most transmitters), the transmitter may not operate correctly. In such cases, it’s important to check if the loop has any excessive load, as this can lead to voltage drops.

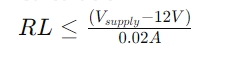

Calculation: The resistance in the loop should comply with the formula:

Where:

- Vsupply is the power supply voltage.

- 0.02A represents the current draw of the transmitter.

If the load resistance exceeds this value, it could cause the output to exceed 20mA.

2. Verify the Measurement Range

Next, verify whether the actual pressure being measured exceeds the transmitter’s specified range. If the measured pressure is greater than the transmitter’s rated range, the transmitter may output a value above 20mA.

Solution: In this case, you would need to either:

- Adjust the measurement range of the transmitter to match the process conditions, or

- Replace the transmitter with one that has a suitable range for the application.

3. Inspect for Damage to the Pressure Transmitter

Pressure transmitters are designed to withstand harsh conditions, but they are not immune to damage, especially if exposed to overload conditions or incorrect handling. If the transmitter has been exposed to pressures beyond its rated capacity or has been improperly installed, it may be damaged.

Solution: Inspect the transmitter for signs of physical damage or malfunction. If any damage is detected, the transmitter may need to be sent back to the manufacturer for repair or replacement.

4. Ensure Proper Wiring Connections

Improper wiring connections can also cause erratic readings or an output greater than 20mA. In many cases, loose connections, poor contacts, or incorrect wiring can lead to intermittent or incorrect output values.

Solution: Double-check all wiring connections at the transmitter terminals, ensuring they are tight and securely attached. If necessary, re-terminate the connections to ensure good contact.

5. Check the Power Supply Wiring

It’s also essential to verify that the power supply wiring is correctly installed. Pressure transmitters typically have specific terminals for power input, and connecting the wires incorrectly can lead to malfunctioning outputs.

Solution: Confirm that the power supply lines are correctly connected to the appropriate terminals on the transmitter. If necessary, consult the transmitter’s manual to ensure the correct configuration.

6. Additional Maintenance and Calibration

In addition to these checks, regular maintenance and calibration are crucial to ensure long-term accuracy and performance of pressure transmitters. Over time, environmental factors such as temperature fluctuations, mechanical stress, or aging components can affect the transmitter’s accuracy.

Solution: Perform periodic calibration and maintenance according to the manufacturer’s recommendations to prevent future issues with the transmitter’s output.

Conclusion:

Pressure transmitters play a critical role in industrial monitoring and control systems, converting physical pressure measurements into electrical signals for processing. If you encounter a situation where the transmitter’s output exceeds 20mA, it’s essential to troubleshoot the issue systematically. Start by checking the power supply, verifying the measurement range, inspecting for damage, and ensuring proper wiring connections. Regular maintenance and calibration can help avoid such issues and extend the lifespan of the transmitter. By following these steps, you can quickly identify the root cause and restore the normal operation of the system.