Introduction

In industrial applications, selecting the right pressure transmitter requires careful consideration of multiple critical specifications and parameters. Choosing the appropriate device ensures accurate measurements, long-term reliability, and compatibility with the operating environment. This article provides a detailed guide on the general specifications and selection criteria for pressure transmitters, along with application scenarios and selection recommendations.

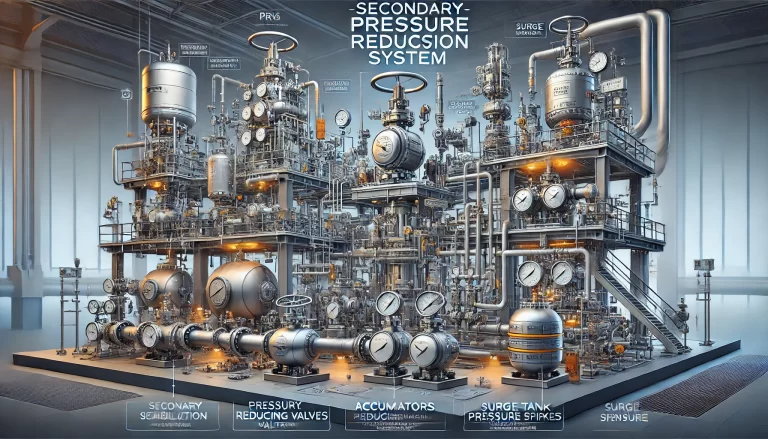

1. Pressure Range

The measurement range of a pressure transmitter should cover both the minimum and maximum operating pressures in the application while leaving a safety margin to avoid overloading. Typical pressure ranges include:

Micro-pressure (0–1 kPa): Used in applications such as cleanrooms and HVAC systems.

Low pressure (0–10 kPa): Suitable for gas pipelines and medical devices.

Medium pressure (0–10 MPa): Used in water treatment and general industrial processes.

High pressure (0–100 MPa): Common in hydraulic systems and oil extraction.

Ultra-high pressure (>100 MPa): Utilized in specialized applications like high-pressure testing and aerospace systems.

Application Example:

A steam boiler system operates at 5 MPa. A pressure transmitter with a measurement range of 0–10 MPa should be selected to ensure safe and accurate readings.

2. Pressure Type

Pressure transmitters measure different types of pressure, depending on the reference point used:

Gauge Pressure (G): Measured relative to atmospheric pressure. Common in gas distribution systems.

Absolute Pressure (A): Measured relative to a perfect vacuum. Used in weather monitoring and vacuum chambers.

Differential Pressure (D): Measures the difference between two pressure points. Common in flow and level measurements.

Application Example:

In a chemical reactor, monitoring the liquid level requires a differential pressure transmitter, which compares the pressure at the liquid surface with the reference point at the tank bottom.

3. Accuracy

Accuracy is a crucial parameter that determines the reliability of pressure measurements. The most common accuracy classifications are:

0.1%–0.5% Full Scale (F.S.): Suitable for general industrial use.

0.05%–0.1% F.S.: Required for precision processes, such as semiconductor manufacturing.

≤0.025% F.S.: Used in laboratory environments and scientific research.

Factors affecting accuracy include:

Zero drift (offset over time)

Linearity error (deviation from a straight-line response)

Temperature drift (variation due to temperature changes)

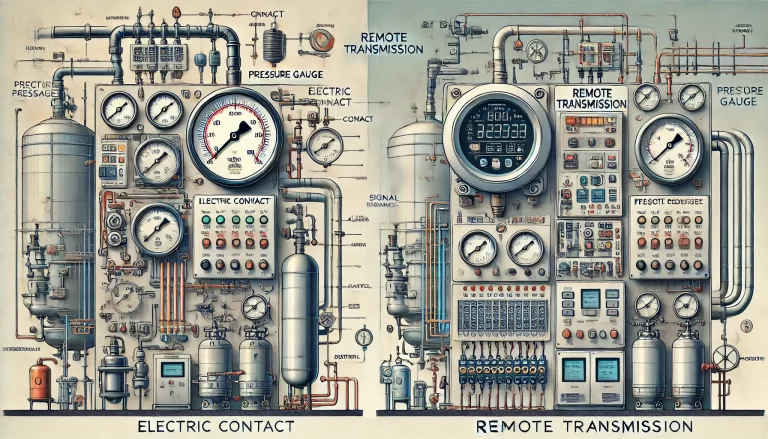

4. Output Signal

Pressure transmitters provide various types of output signals, depending on system requirements:

Analog Signals:

4–20 mA (Industry standard, strong noise immunity, suitable for long-distance transmission)

0–5V, 0–10V (Short-distance applications)

Digital Signals:

HART (4–20mA + digital communication) (Allows remote configuration and diagnostics)

Modbus RS485 (Supports multi-device connections)

CAN bus (Used in industrial automation)

I²C/SPI (Embedded systems applications)

Application Example:

A pressure transmitter used in a remote oil pipeline monitoring system should have a 4–20 mA output with HART for long-distance transmission and remote configuration.

5. Power Supply

Pressure transmitters require different power supply levels based on their application:

24V DC (Standard for industrial use)

12V DC (Portable equipment)

5V DC (Low-power applications)

220V AC (Special cases requiring high-power operation)

6. Material Selection

Material selection is crucial for ensuring longevity and chemical compatibility:

Sensor Material:

304/316L Stainless Steel: Corrosion-resistant, ideal for general gas and liquid measurements.

Ceramic diaphragm: Suitable for aggressive chemicals.

Hastelloy, Tantalum, PTFE: Used in highly corrosive environments.

Transmitter Housing:

Aluminum alloy: Standard industrial applications.

Stainless steel: Corrosion-resistant, used in chemical processing.

Plastic-sealed housing: Provides waterproof and explosion-proof protection.

7. Temperature Considerations

Operating temperature: -40°C to +100°C (Standard); High-temperature applications can reach 300°C.

Temperature compensation range: Typically -10°C to +70°C.

High-temperature measurement techniques:

Use of cooling elements (e.g., condensate tubes)

Remote diaphragm transmitters to isolate the sensor from heat sources.

8. Mechanical & Electrical Connections

Process Connection (Pressure Interface):

Threaded connections: M20×1.5, G1/4″, NPT 1/4″ (Common for general industrial applications)

Flange connection: Used in high-pressure environments.

Sanitary tri-clamp: Preferred in food and pharmaceutical industries.

Electrical Connection:

M12, DIN 43650, aviation connectors, and terminal blocks.

9. Overload & Burst Pressure

Overload pressure: 1.5–3 times full-scale pressure.

Burst pressure: 5–10 times full-scale pressure, ensuring operational safety.

10. Protection Rating (IP & Explosion-proof Certification)

Ingress Protection (IP) Rating:

IP65: General industrial use.

IP67/IP68: Suitable for submerged or harsh environments.

Explosion-proof Certifications:

ATEX, IECEx (Intrinsic safety/explosion-proof for petrochemical and mining industries).

SIL (Safety Integrity Level) (Required for hazardous applications).

11. Industry Certifications

CE, RoHS: General industrial compliance.

ATEX, IECEx: Explosion-proof requirements.

FDA, 3A: Food and pharmaceutical industries.

SIL 2/3: Safety system compliance.

EAC, CSA: International certifications.

12. Special Features

Wireless communication: LoRa, NB-IoT, BLE for IoT applications.

Self-diagnostic capabilities.

Remote monitoring and data logging.

Selection Guide

| Application | Recommended Range | Accuracy | Output Signal | Protection | Certification |

|---|---|---|---|---|---|

| Aerospace | 0–10 MPa | ≤0.05% | 4–20mA + HART | IP67 | CE, SIL |

| Food/Pharmaceutical | 0–1 MPa | 0.1% | 0–10V | IP68, Sanitary | FDA, 3A |

| Oil & Gas | 0–100 MPa | 0.05% | Modbus RS485 | ATEX, IECEx | EAC, CSA |

Conclusion

Selecting a pressure transmitter requires a comprehensive evaluation of factors such as pressure range, accuracy, output signal, power supply, materials, environmental conditions, and industry certifications. By understanding these specifications, you can ensure the chosen device meets the demands of your industrial application effectively.