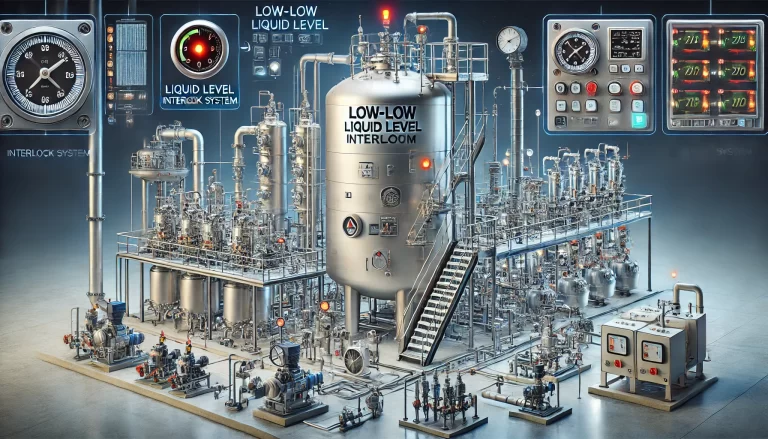

In industrial systems, the management of liquid levels is crucial to the safe and efficient operation of equipment. One critical aspect of this is the use of low-low liquid level interlocks, which are designed to protect systems from damage due to low liquid levels. These interlocks automatically activate certain protective measures when the liquid level in a tank, vessel, or system drops below a predetermined point. Below is a detailed explanation of why low-low liquid level interlocks are important in industrial settings.

1. Prevention of Dry Running in Pumps

One of the most common and significant reasons for setting a low-low liquid level interlock is to protect pumps from “dry running.” Pumps are designed to move liquids, and their operation depends on the continuous supply of the liquid to be pumped. When the liquid level drops too low, the pump may start running without liquid, leading to “dry running.” This condition can cause excessive heat build-up and wear on the pump components. Prolonged dry running can lead to irreversible damage to the pump, such as overheating the motor, damaging seals, and causing the pump to fail completely.

The low-low liquid level interlock acts as a safeguard by automatically shutting down the pump or triggering an alarm before the liquid level becomes critically low. This helps prevent damage to the pump and extends its operational lifespan.

2. Protection of Sensitive Equipment

In many industrial processes, certain equipment such as heat exchangers, reactors, and cooling systems require a constant supply of liquid for proper operation. If the liquid level falls too low, the equipment may not function as intended. For example, in heat exchangers, insufficient liquid flow can result in overheating, leading to potential damage to the heat exchange surfaces or even a catastrophic failure.

Similarly, in reaction vessels or reactors, low liquid levels can result in poor mixing or an inability to maintain necessary temperature and pressure conditions, compromising product quality and potentially causing safety hazards. The low-low liquid level interlock system can prevent such scenarios by stopping or diverting the process flow to ensure the system remains protected.

3. Prevention of Overheating or Overpressurization

In some industrial processes, liquid levels are used to regulate temperature and pressure. For instance, in cooling systems, liquid is often used to dissipate heat generated by equipment. When the liquid level drops too low, the system may no longer be able to regulate temperature effectively, leading to overheating of equipment. This can cause components to expand, warp, or even crack, leading to expensive repairs or replacements.

Similarly, in pressurized systems such as reactors or tanks, low liquid levels can result in a buildup of pressure. Insufficient liquid can reduce the ability to control pressure, potentially leading to dangerous overpressure situations, leaks, or equipment failure. A low-low liquid level interlock helps to prevent these issues by shutting down operations when liquid levels are too low, thereby maintaining a safe operating environment.

4. Ensuring Process Stability

Many industrial processes, especially in chemical and manufacturing plants, require the maintenance of stable conditions for optimal performance. These processes often rely on precise control of variables such as temperature, pressure, and liquid levels. If the liquid level falls too low, it can disrupt the process, leading to unstable reactions or suboptimal product quality.

For instance, in continuous production processes, low liquid levels can cause fluctuations in the flow rates of ingredients, resulting in inconsistent product batches. The low-low liquid level interlock system ensures that liquid levels remain within the safe operating range, thereby stabilizing the process and preventing costly downtime or defective products.

5. Environmental and Safety Considerations

In certain applications, low liquid levels can lead to hazardous situations, including spills or the release of harmful substances into the environment. For example, in chemical or oil processing industries, a drop in liquid levels can result in leaks of hazardous liquids or gases, posing significant risks to workers and the surrounding environment.

By preventing the operation of equipment when liquid levels are dangerously low, the low-low liquid level interlock system can help mitigate the risk of spills, leaks, and other environmental hazards. This ensures that industrial operations are conducted safely and in compliance with environmental regulations.

6. Enhancing System Reliability and Reducing Maintenance Costs

Low-low liquid level interlocks enhance the overall reliability of a system by ensuring that critical processes are not interrupted or damaged due to low liquid levels. By preventing equipment failure or damage, these interlocks can reduce the frequency of maintenance interventions and the associated costs. Additionally, by extending the life of pumps, heat exchangers, and other critical equipment, they contribute to long-term cost savings for the plant or facility.

Conclusion

In conclusion, the low-low liquid level interlock is an essential safety and operational feature in many industrial systems. It plays a crucial role in preventing equipment damage, ensuring process stability, maintaining safe operating conditions, and safeguarding against environmental hazards. By automatically shutting down pumps or other equipment when liquid levels fall below a critical point, these interlocks help prevent costly repairs, enhance system reliability, and contribute to the overall efficiency and safety of industrial operations. For these reasons, low-low liquid level interlocks are a valuable component of any industrial process that relies on liquid management.