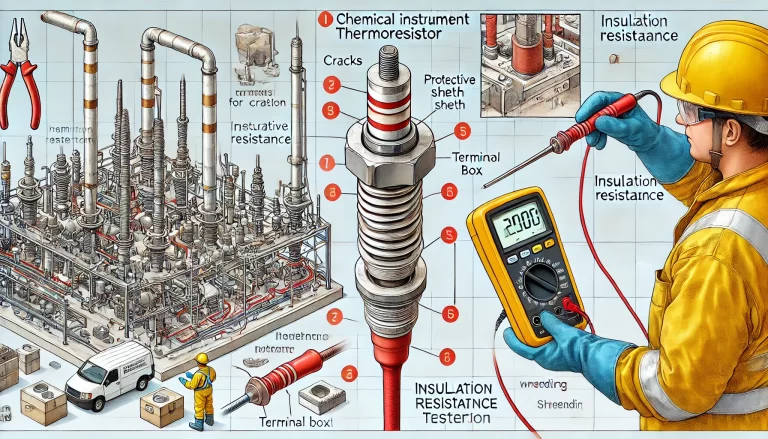

Thermoresistors are critical components in chemical instrumentation for accurate temperature measurement. Proper inspection of these devices is essential to ensure they function correctly and provide reliable data. Below are the detailed steps for inspecting thermoresistors:

1. Visual Inspection

- Protective Sheath Check: Examine the thermoresistor’s protective sheath for any visible damage, such as cracks, deformation, or corrosion. Any of these issues may impair the accuracy of temperature readings or even cause complete failure of the thermoresistor.

- Terminal Box Condition: Inspect the condition of the terminal box. Ensure that it is intact, free from damage or signs of moisture. Check for corrosion or oxidation at the terminal connections. Loose or poorly connected terminals can cause measurement errors due to poor contact, which should be addressed immediately.

2. Insulation Resistance Check

- Test Equipment: Use a 500V insulation resistance tester, which is typically suitable for thermoresistors. This ensures the insulation resistance between the sensor elements and the protective sheath meets the required standards.

- Testing Process: Connect the two test leads of the insulation resistance tester to the thermoresistor’s measurement element and the protective sheath. The insulation resistance should be measured, and it should generally not fall below 20 MΩ. A lower value indicates potential issues with insulation, which could lead to measurement inaccuracies or equipment failure.

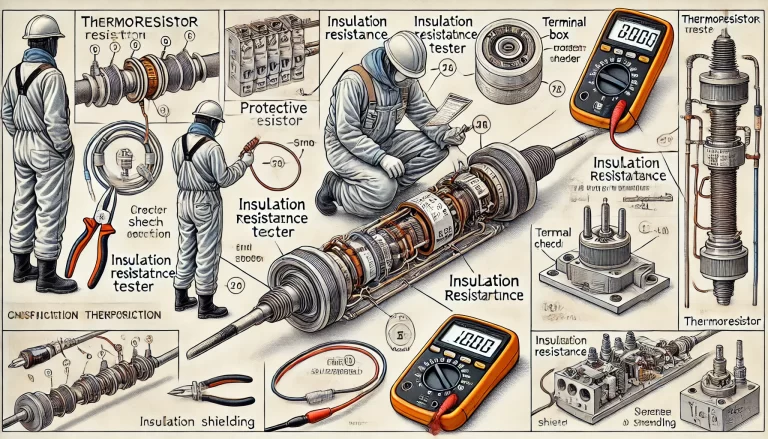

3. Resistance Measurement

- Measurement Device: Use a high-precision multimeter or bridge to measure the resistance of the thermoresistor. Ensure the device is set to the appropriate resistance measurement mode.

- Disconnection: Disconnect the thermoresistor from the measuring circuit to avoid interference. Connect the test probes of the multimeter or bridge to the thermoresistor’s terminal connections to measure its resistance.

- Comparison with Standard: Compare the measured resistance with the thermoresistor’s temperature-resistance characteristic curve or the manufacturer’s specifications. The measured resistance should correspond to the expected value for the given temperature, ensuring the thermoresistor is functioning within its normal operational range.

4. Wiring and Connection Inspection

- Wire Condition: Inspect the wiring between the thermoresistor and the display instrument or control system. Ensure there are no visible signs of wear, such as cuts, fractures, or short circuits.

- Shielding and Grounding: Check if the shield layer of the wiring is grounded properly. Poor grounding of the shielding can introduce electromagnetic interference from external sources, potentially affecting the accuracy of temperature measurements. Proper shielding and grounding are essential for reliable operation in industrial settings.

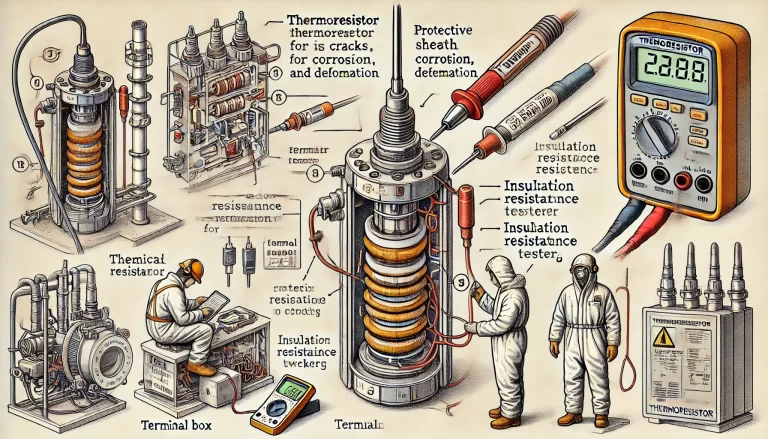

5. System Integration and Calibration Check

- Reinstallation and Reconnection: After completing the above checks, reinstall the thermoresistor into its original position and reconnect all wiring securely. Ensure that the system is back in normal operating conditions.

- Operational Check: Observe the thermoresistor’s performance during real-world operating conditions. Verify whether the measured values align with the actual temperature of the system. Any significant discrepancies or fluctuations should be investigated, and further corrective action may be required to ensure the device’s accuracy.

Conclusion

Regular inspection of thermoresistors is critical for maintaining accurate temperature measurements and ensuring the smooth operation of chemical processes. By following these steps—visual checks, insulation resistance testing, resistance measurement, wiring inspection, and system integration checks—you can ensure that thermoresistors function properly, helping prevent operational issues and ensuring the reliability of temperature readings in chemical production environments.

Safety precautions should always be followed when handling electrical equipment. If any issues are found during the inspection, timely maintenance or replacement of the thermoresistor is crucial to avoid potential process interruptions.