When diagnosing faults in industrial instruments such as flow meters or level transmitters, a systematic approach is essential for accurate detection. The following steps can guide the process of troubleshooting and resolving issues:

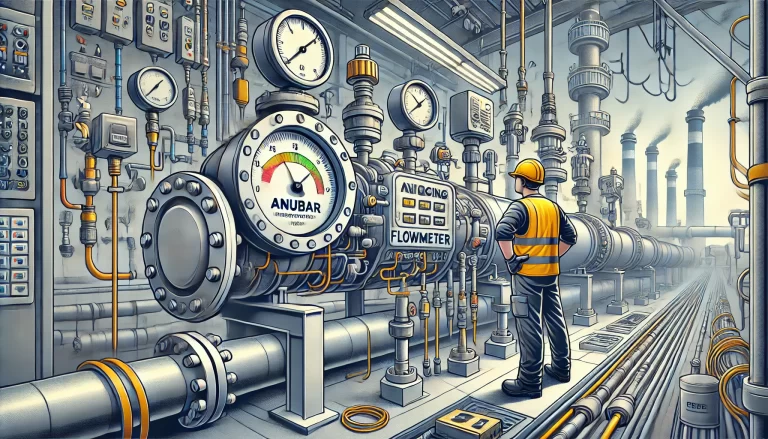

1. Visual Inspection

A detailed visual inspection is often the first step in identifying issues with the instrument.

Check the instrument housing: Inspect the instrument’s outer casing for signs of physical damage such as cracks, dents, corrosion, or deformation. These issues can affect the internal components and, in severe cases, lead to internal circuit damage.

Examine the display: Inspect the display screen for damage such as cracks, flickering, or complete blackouts. Ensure that all digits and symbols are clear and legible. If the display is abnormal, the issue could be with the screen itself or the related circuits that control it.

Inspect connectors and cables: Check all interfaces, plugs, and sockets for signs of looseness, corrosion, wear, or damage. Also, ensure that the connecting cables are intact, without any visible wear, breaks, or short circuits. Poor connections and damaged cables are common causes of instrument failures.

2. Basic Functional Testing

After completing the visual inspection, conduct some basic functionality tests to assess the instrument’s operational status.

Power-on test: Switch on the instrument and observe if it powers up without unusual noises, smells, or smoke. If any of these symptoms are present, it may indicate a serious electrical fault within the power supply or internal circuits.

Parameter settings check: Test the instrument’s ability to set and adjust parameters. Verify that the settings can be modified and that changes take effect properly. If there is an issue with parameter adjustments, this could indicate problems with the instrument’s control circuitry or software.

Input/output signal test: Based on the type of instrument, input a known standard signal and check the output. The output should be stable, accurate, and proportional to the input signal. Any discrepancies could point to faults in the sensor, signal processing circuits, or output circuits.

3. Performance Testing

Once basic functionality is verified, perform more in-depth performance tests to ensure the instrument is operating within specifications.

Accuracy testing: Use a high-precision reference instrument to calibrate and test the instrument’s measurement accuracy. Compare the instrument’s readings against the standard values and calculate any error. If the error exceeds the allowable range, recalibration or repairs may be required.

Stability testing: Run the instrument continuously for an extended period and monitor whether the readings remain stable or fluctuate. If the readings drift, this could indicate aging components, thermal drift (temperature-related issues), or other internal problems that need addressing.

Response time testing: Apply a sudden change in the input signal and measure the time it takes for the instrument to stabilize and display the correct reading. If the response time is too long or too short, it may not meet the instrument’s specifications and could point to issues within the response circuitry.

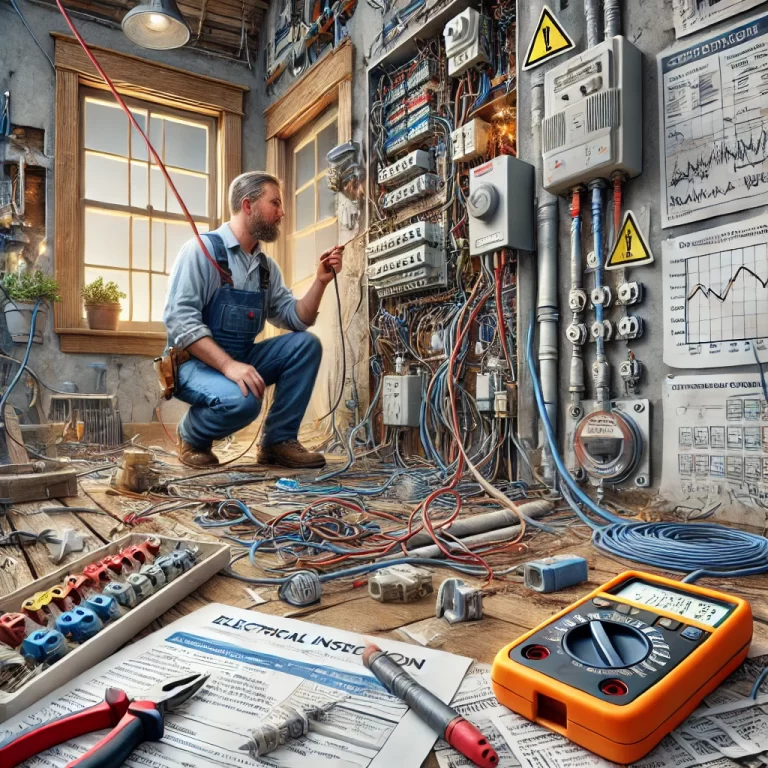

4. Using Tools and Technology for Diagnosis

In many cases, advanced tools and diagnostic software can help pinpoint issues more effectively.

Testing devices: Tools such as a multimeter can measure electrical parameters like voltage, current, and resistance. An oscilloscope can help observe waveforms and frequencies of the signals. By comparing these measurements with the instrument’s normal operating parameters, faults can be detected more precisely.

Software diagnostics: For smart instruments, use proprietary diagnostic software to communicate with the device. This software can read the instrument’s status, error codes, and other diagnostic data, which can significantly speed up fault detection and localization.

Replacement method: If a specific component is suspected of failing, consider replacing it with a known good part. If the instrument resumes normal operation, the replaced component was likely the source of the failure.

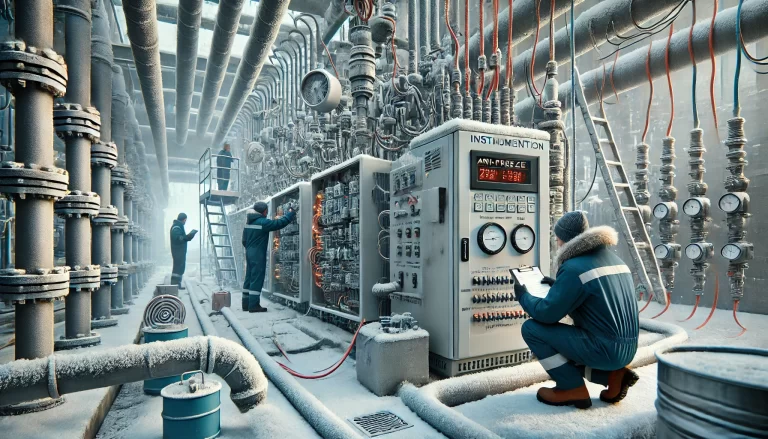

5. Comprehensive Analysis

Diagnosing instrument faults involves more than just performing tests. It’s important to consider multiple factors that could affect performance.

Consider the operating environment: Evaluate the conditions in which the instrument is operating, such as temperature, humidity, vibrations, and electromagnetic interference. Harsh environmental factors can degrade the performance of the instrument over time, and recognizing these potential stressors may help identify the root cause of the failure.

Review historical data: Check the instrument’s operational history, including past maintenance and failure records. This can provide insight into whether the fault has occurred before and how similar issues were handled. Patterns in historical data can help you identify recurring faults, which could point to a design issue or a specific component prone to failure.

Multifactorial analysis: Combining the results from visual inspections, functional tests, performance tests, and environmental factors will lead to a more comprehensive understanding of the instrument’s condition. Analyzing all factors together allows for a more accurate diagnosis and ensures that the fault is correctly identified.

Conclusion

Diagnosing faults in industrial instruments requires a thorough and systematic approach. By following these steps—visual inspection, basic functional testing, performance testing, utilizing tools, and considering environmental factors—technicians can efficiently identify and resolve issues. Comprehensive analysis of the instrument’s condition, combined with historical data and careful testing, ensures that faults are accurately diagnosed and addressed, minimizing downtime and improving the reliability of critical equipment.