With the rapid advancement of artificial intelligence (AI) and automation technologies, numerous traditional professions face transformation or even potential obsolescence. Instrumentation technicians, essential in industrial settings, are responsible for installing, maintaining, and calibrating various instruments, such as sensors and controllers. Given the rise of AI and smart automation, the question arises: will AI replace instrumentation technicians? This article analyzes this issue from multiple perspectives.

1. AI’s Potential to Replace Instrument Technicians

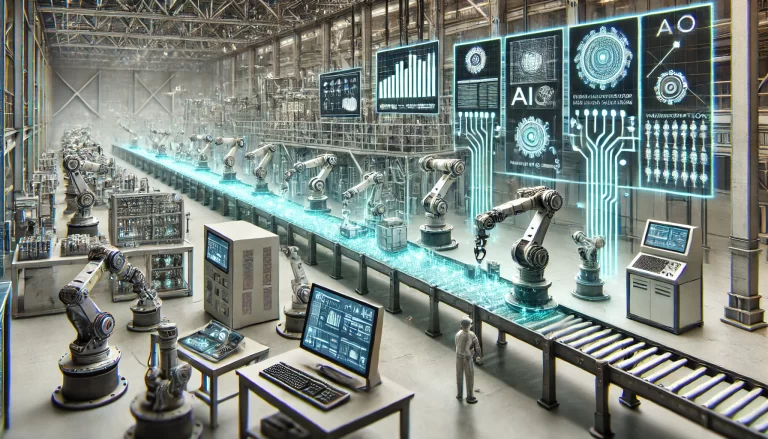

Automation of Repetitive Tasks

AI-powered industrial robots and software excel in handling standardized, repetitive tasks, including real-time data monitoring and basic fault diagnosis. Many routine instrumentation maintenance tasks, such as data logging and parameter adjustments, could be increasingly managed by automated systems, reducing the need for manual intervention.

Predictive Maintenance Revolution

Predictive maintenance, powered by AI and machine learning, analyzes real-time equipment data to forecast potential failures before they occur. Companies such as Siemens and General Electric have already implemented AI-driven maintenance solutions that automatically generate maintenance schedules, significantly reducing the reliance on human inspections and emergency repairs.

Remote Monitoring and Control

With the integration of AI and the Internet of Things (IoT), industrial plants can remotely monitor and control instrument performance. AI-powered monitoring systems can analyze vast amounts of sensor data, detect anomalies, and even implement corrective measures without the need for on-site human intervention. This technological shift reduces dependence on field technicians, especially in hazardous or remote locations.

2. The Irreplaceable Value of Instrument Technicians

Despite advancements in AI and automation, human expertise remains indispensable in several key areas:

Adapting to Complex and Unpredictable Environments

Industrial settings often present unique challenges, such as extreme temperatures, high-pressure environments, and exposure to corrosive substances. Installing, calibrating, and repairing instruments in such conditions requires hands-on expertise and adaptability. AI may struggle to account for unpredictable factors that human technicians can quickly assess and respond to.

Precision Calibration and Human Judgment

While AI can enhance accuracy in standardized tasks, certain high-precision instrument calibrations require human expertise. Manual fine-tuning, error corrections, and adjustments—particularly in environments lacking comprehensive standardization—still rely on experienced professionals who can assess nuances that AI may overlook.

Emergency Response and On-Site Decision-Making

In cases of unexpected system failures, such as pipeline leaks or equipment malfunctions, immediate human intervention is often necessary. While AI can assist in diagnostics, real-time decision-making under pressure remains a stronghold of human expertise. Technicians play a critical role in assessing risks, prioritizing responses, and implementing rapid solutions.

Cross-Disciplinary Collaboration

Instrumentation technicians frequently collaborate with electrical, mechanical, and process engineering teams. This cross-disciplinary coordination ensures seamless integration of new instruments and troubleshooting of complex system issues. AI, while efficient in data analysis, lacks the ability to navigate the intricate interpersonal and strategic aspects of interdisciplinary teamwork.

3. Balancing Industry Demand and AI Adoption

Cost and Implementation Barriers

While large enterprises may rapidly adopt AI-powered maintenance solutions, small and medium-sized businesses often lack the financial resources for full-scale automation. As a result, traditional instrument technicians will continue to play a vital role in industries where AI adoption is gradual due to budget constraints.

Regulatory and Safety Compliance

In highly regulated industries such as nuclear energy, oil and gas, and pharmaceuticals, strict safety and compliance regulations often mandate human oversight in maintenance and inspections. These regulatory frameworks ensure that critical decisions remain within human control to mitigate liability and enhance accountability.

Limitations of AI in Non-Standardized Environments

Many industrial systems involve aging equipment and non-standardized instruments, which may not be easily integrated into AI-based automation frameworks. The reliability of AI diminishes in cases where data-driven algorithms lack sufficient historical data or predefined parameters for effective operation.

4. Future Trends: Human-AI Collaboration and Skill Evolution

From Operators to Supervisors

The role of instrument technicians is expected to evolve from hands-on operators to AI system supervisors. Rather than performing routine manual tasks, technicians will oversee AI-driven processes, analyze system performance, and make high-level decisions regarding maintenance strategies.

Upskilling for the AI Era

To remain competitive in an AI-driven industrial landscape, instrumentation technicians will need to expand their skill sets. Key areas of knowledge development include:

AI and Machine Learning: Understanding how AI-driven predictive maintenance works

Data Analytics: Interpreting sensor data for more effective decision-making

Programming and IoT Integration: Learning basic coding (Python, SQL) and working with industrial IoT platforms

Cybersecurity Awareness: Ensuring that automated systems remain secure against cyber threats

Opportunities in Emerging Fields

As industries such as renewable energy and smart manufacturing grow, the demand for highly skilled technicians in new instrumentation technologies—such as intelligent sensors and edge computing devices—will increase. These emerging roles offer higher value-added opportunities for professionals who embrace technological advancements.

Conclusion: Transformation, Not Elimination

AI will not entirely replace instrumentation technicians but will significantly reshape their job functions. Low-skilled, repetitive roles may decline, while demand for high-skilled, tech-savvy professionals will rise. To stay relevant, instrumentation technicians must embrace continuous learning and adapt to an AI-integrated future, leveraging their expertise in collaboration with smart technologies. By evolving alongside AI, professionals in this field can secure a meaningful and sustainable role in the industrial landscape of tomorrow.