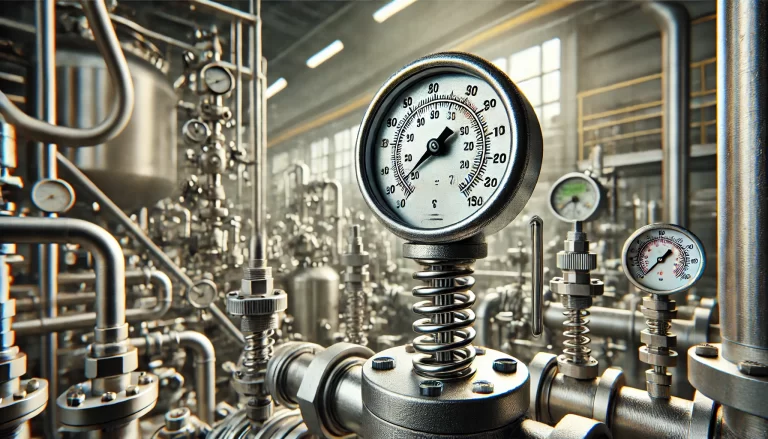

Temperature monitoring is a critical aspect of nuclear power plant operations, ensuring the safety and efficiency of various processes. Accurate temperature measurements help in preventing equipment failure, optimizing energy efficiency, and maintaining operational safety. Different types of temperature measurement devices are used in nuclear facilities, including thermocouples, resistance temperature detectors (RTDs), and bimetallic thermometers. Among these, bimetallic thermometers are widely used for measuring low to medium temperatures due to their reliability, simplicity, and cost-effectiveness.

What is a Bimetallic Thermometer?

A bimetallic thermometer is a field instrument used for measuring temperatures in the range of -80°C to +500°C, suitable for monitoring the temperature of liquids, steam, and gaseous media. It is commonly employed in various industrial sectors, including nuclear power plants, chemical and petrochemical industries, power engineering, food processing, mechanical manufacturing, and general plant construction.

Working Principle of Bimetallic Thermometers

The core component of a bimetallic thermometer is a bimetallic strip, which consists of two different metals with varying coefficients of thermal expansion. These metals are bonded together and formed into a helical or spiral shape. When exposed to temperature changes, the differing expansion rates of the metals cause the strip to bend or twist. This movement is transferred to a pointer mounted on a dial scale, providing a direct temperature reading.

The construction of a bimetallic thermometer typically includes:

- Sensing Element: A coiled or helically wound bimetallic strip housed within a protective sheath.

- Fixed End: One end of the strip is securely mounted within the casing.

- Free End: The other end is attached to a spindle or pointer, which rotates according to the thermal expansion.

- Dial Indicator: Displays the corresponding temperature value based on the angular displacement of the free end.

Advantages of Bimetallic Thermometers

Bimetallic thermometers offer several advantages that make them suitable for nuclear power plant applications, including:

- Wide Temperature Range: Capable of measuring temperatures between -80°C and +500°C.

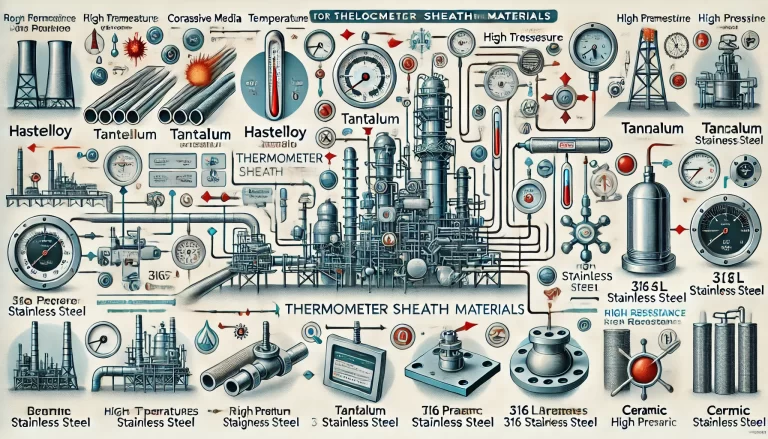

- Durability and Reliability: Resistant to harsh environments, mechanical stress, and vibrations.

- Cost-Effective Solution: Compared to other temperature sensors, bimetallic thermometers are relatively inexpensive.

- Easy Installation and Maintenance: They do not require external power sources, making them suitable for remote applications.

- Instantaneous Readings: Provide direct and real-time temperature readings without complex signal processing.

Applications in Nuclear Power Plants

In nuclear power plants, bimetallic thermometers are typically used for:

- Monitoring cooling systems: Ensuring that reactor cooling water remains within safe operating limits.

- Steam pipelines: Measuring temperatures in steam generation and distribution systems.

- Turbine operations: Monitoring temperature variations in turbine components to prevent overheating.

- Auxiliary systems: Checking temperatures in secondary systems, such as lubricants and heat exchangers.

Despite their advantages, bimetallic thermometers are generally used in applications where high accuracy and rapid response times are not critical, as they have a slower response compared to electronic sensors like thermocouples and RTDs.

Maintenance and Calibration Considerations

To ensure the accuracy and longevity of bimetallic thermometers in nuclear power plants, regular maintenance and calibration are essential. Some key practices include:

- Periodic Calibration: Verifying readings against a certified reference thermometer to maintain measurement accuracy.

- Environmental Protection: Ensuring the thermometer is protected from extreme mechanical shocks and corrosive environments.

- Replacement of Worn Components: Inspecting and replacing damaged dials or protective casings to prevent erroneous readings.

Conclusion

Bimetallic thermometers remain an essential tool for temperature monitoring in nuclear power plants due to their simplicity, cost-effectiveness, and robust performance. While they may not offer the high precision of advanced digital sensors, they provide a reliable and efficient solution for many industrial applications. Proper installation, maintenance, and periodic calibration can further enhance their effectiveness, ensuring the safe and efficient operation of nuclear facilities.