A temperature sensor (temperature transducer) is a device that detects temperature changes and converts them into a usable output signal. These sensors are essential components in temperature measurement instruments. Temperature sensors are widely used in industrial processes, medical equipment, environmental monitoring, and more. There are several common types of temperature sensors, each with unique characteristics and applications. Below, we discuss the most widely used types and their key features.

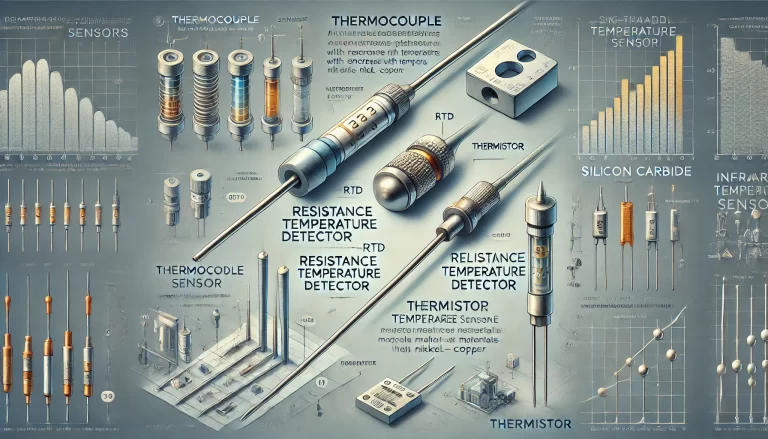

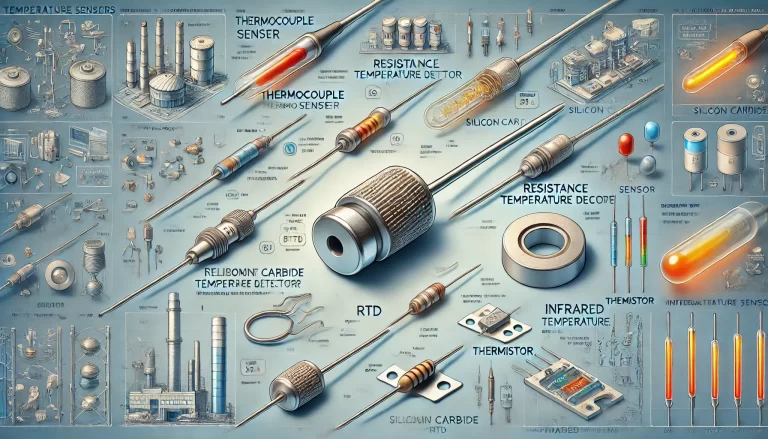

1. Thermocouple (Thermocouple Sensor)

A thermocouple is made from two different metal wires joined at one end, which generates a voltage when exposed to temperature changes. This voltage is then used to measure the temperature. Thermocouples are popular due to their broad temperature measurement range, from extremely low temperatures to high temperatures, and their durability in harsh environments.

Advantages:

- Wide temperature range: Typically from -200°C to 2000°C, depending on the metal combination.

- Fast response time and high accuracy in extreme temperatures.

- Relatively simple and cost-effective.

Disadvantages:

- Less precise than other types at lower temperatures.

- Susceptible to interference and noise, requiring proper calibration.

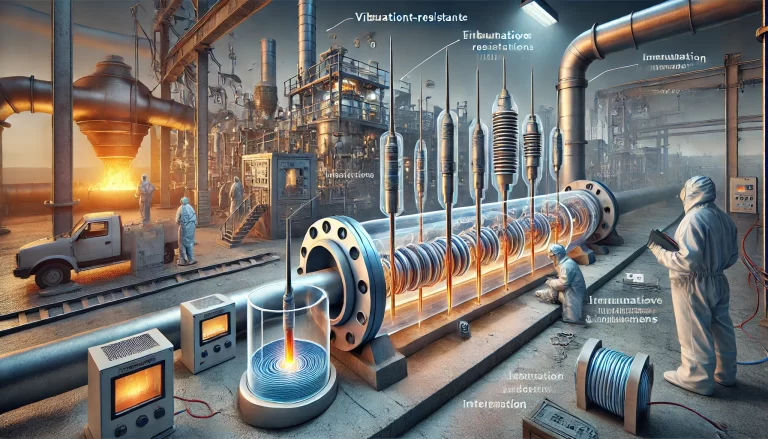

Applications: Thermocouples are commonly used in high-temperature environments, such as in industrial furnaces, jet engines, and metal processing.

2. Resistance Temperature Detector (RTD)

An RTD is a temperature sensor that works by measuring the resistance of a metal, typically platinum, which increases with temperature. The most common types of RTDs are Pt100 and Pt1000, where the “100” or “1000” refers to the resistance in ohms at 0°C.

Advantages:

- High accuracy and stability, especially at a wide range of temperatures.

- Excellent linearity: The relationship between resistance and temperature is nearly linear, making calibration easier.

- Long-term stability with minimal drift over time.

Disadvantages:

- More expensive than thermocouples.

- Generally, slower response time compared to thermocouples.

Applications: RTDs are widely used in precision temperature measurements, such as in laboratory equipment, HVAC systems, and food processing.

3. Silicon Carbide Sensor

Silicon carbide (SiC) sensors use the unique properties of silicon carbide materials to detect temperature changes. These sensors are known for their high resistance to heat, and they are often used in environments where extremely high temperatures are encountered.

Advantages:

- High temperature tolerance, withstanding temperatures up to 1600°C.

- Low heat capacity, which leads to faster response times.

- Excellent stability in harsh conditions.

Disadvantages:

- Expensive and less commonly available compared to other sensor types.

- Limited application range for low-temperature measurements.

Applications: Silicon carbide sensors are ideal for high-temperature applications such as in aerospace, furnace monitoring, and automotive industries.

4. Thermistor

A thermistor is a type of temperature-sensitive resistor, where the resistance changes significantly with temperature. Thermistors typically use materials like nickel-copper (NiCu) or platinum-rhodium (PtRh) for temperature sensing. They are highly sensitive to small changes in temperature.

Advantages:

- Very high sensitivity, allowing precise temperature measurement over narrow temperature ranges.

- Compact and inexpensive, making them ideal for consumer electronics and small appliances.

Disadvantages:

- Limited temperature range, typically from -50°C to 150°C.

- Non-linear resistance-temperature relationship, requiring complex calibration for precise measurements.

Applications: Thermistors are commonly used in applications such as temperature sensors for battery packs, medical devices, and automotive temperature monitoring.

5. Infrared Temperature Sensor

Infrared (IR) temperature sensors detect the infrared radiation emitted by an object’s surface and calculate its temperature. Unlike contact-based sensors, infrared sensors can measure temperature without making direct contact with the object. This is especially useful for measuring the temperature of moving objects or items that are difficult or dangerous to touch.

Advantages:

- Non-contact measurement, which prevents damage to objects and is ideal for hazardous materials.

- Capable of measuring high temperatures and moving objects.

- Quick response time.

Disadvantages:

- Affected by the emissivity of the object’s surface, requiring calibration for accurate readings.

- Limited to surface temperature measurement, not suitable for internal temperature measurements.

Applications: Infrared sensors are extensively used in industries such as electronics manufacturing, medical thermography, automotive diagnostics, and even in consumer products like infrared thermometers.

Conclusion

Temperature sensors play a critical role in modern industrial, medical, and environmental applications. The choice of temperature sensor depends on factors such as the required temperature range, accuracy, sensitivity, response time, and environmental conditions. Whether you need a thermocouple for high-temperature applications or an infrared sensor for non-contact measurements, understanding the different types of temperature sensors can help you select the most appropriate one for your needs.