Introduction

In the food industry, stringent requirements are placed on equipment used in production processes to ensure product quality, safety, and hygiene. Vibrating rod level switches and tuning fork level switches play a critical role in this domain, requiring careful attention to material, performance, safety, maintenance, and regulatory compliance. This article outlines the specific demands for such instruments in hygienic applications, providing detailed insights into their technical and functional standards.

Material Requirements

Food-Grade Materials

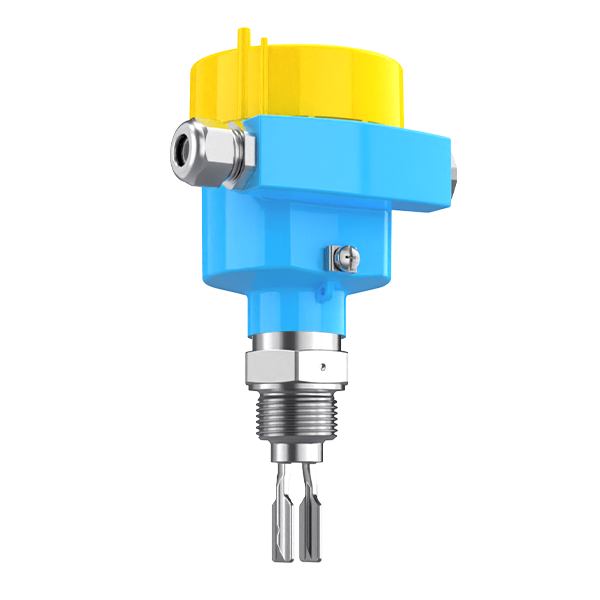

The parts of the instruments that come into contact with food must be constructed from materials that comply with food safety standards. Stainless steel 316L, renowned for its excellent corrosion resistance and durability, is a preferred choice. For instance, Zero Instrument’s vibrating rod and tuning fork level switches utilize 316L stainless steel for their probes and installation components, ensuring they meet stringent food-grade requirements.

Surface Finish

A smooth surface finish is essential to minimize dirt accumulation and facilitate cleaning. Standards typically require a surface roughness (Ra) below 0.5 μm. Zero Instrument’s tuning fork level switches feature polished probes with a surface roughness below 3 μm, suitable for food production environments.

Performance Requirements

High Precision and Reliability

Accurate measurement and stable performance are critical in monitoring and controlling levels in food production. Instruments must maintain precision even under fluctuating conditions. For example, Zero Instrument’s level switches undergo extensive reliability testing and achieve SIL2/3 functional safety certification, ensuring dependable performance.

Strong Interference Resistance

The food industry presents complex operational environments, with potential interference from foam, bubbles, viscous liquids, or vibrations. The instruments must withstand such challenges without compromising accuracy. Vibrating rod level switches from Zero Instrument utilize amplitude and frequency adjustments to detect material levels accurately, demonstrating superior interference resistance.

Adaptability to Diverse Materials

Food production involves a wide range of materials, including solids, liquids, and viscous substances. Instruments must adapt to varying densities, particle sizes, and viscosities. For example, Zero Instrument’s Tube-11 vibrating rod switch measures solid materials with densities as low as 0.2 g/cm³, while their Ring-11 tuning fork switch handles liquid densities down to 0.5 g/cm³, making them versatile for most food production needs.

Safety Requirements

Explosion Protection

In environments where flammable or explosive materials are present, level switches must comply with explosion-proof certifications, such as intrinsic safety (Ex i) and flameproof protection (Ex d). Zero Instrument’s products are certified for intrinsic and flameproof safety, ensuring secure operations in hazardous conditions.

Ingress Protection

To prevent damage from dust or moisture, instruments should meet a high ingress protection standard, such as IP67 or higher. This ensures durability and consistent performance, even in harsh conditions.

Maintenance and Hygiene

Easy Installation and Cleaning

Design simplicity is key to ensuring hygienic maintenance. Instruments should allow for quick disassembly and cleaning. Sanitary quick-clamp connections are commonly used to facilitate this process, as seen in Zero Instrument’s level switches.

Dead Zone Elimination

Both the internal and external structures of the instruments must avoid dead zones where materials can accumulate. Polished and streamlined probe designs ensure minimal residue build-up, enhancing hygiene and simplifying cleaning.

Compliance and Certifications

Adherence to Standards

Level switches for food applications must comply with relevant safety and hygiene regulations, such as food safety laws and industry-specific sanitary standards.

Independent Certifications

Certifications from authoritative bodies, such as SIL (Safety Integrity Level), CE, and 3C, attest to the instruments’ safety and reliability. Zero Instrument’s level switches, with certifications from recognized agencies, exemplify high reliability and compliance.

Conclusion

Hygienic applications in the food industry demand that vibrating rod and tuning fork level switches meet exacting standards in material selection, performance, safety, maintenance, and regulatory compliance. These requirements aim to ensure instrument reliability, safety, and hygiene, ultimately safeguarding food quality and consumer health. By adhering to such standards, companies like Zero Instrument provide reliable solutions that support efficient and safe food production processes.