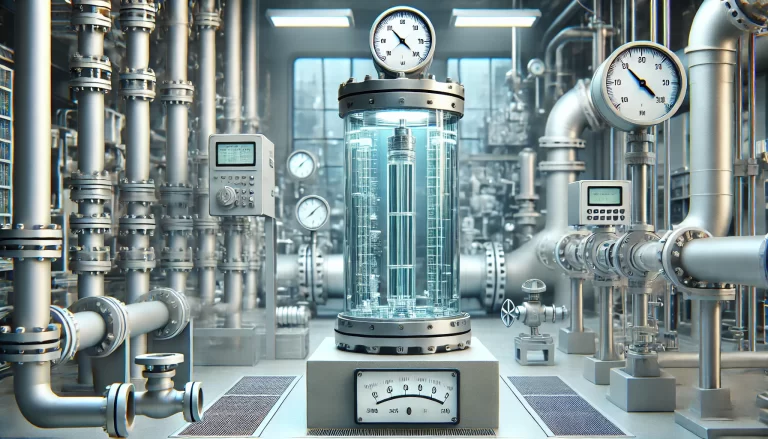

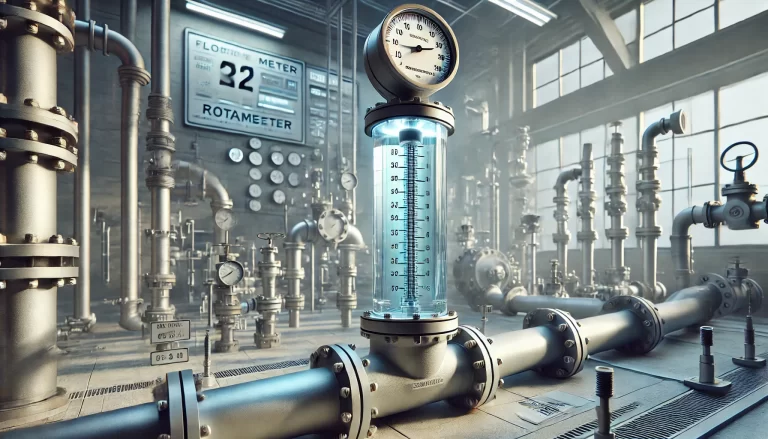

Float flow meters, also known as rotameters, are commonly used in industrial and laboratory settings to measure the flow rate of liquids or gases. To ensure that the selected float flow meter meets operational requirements, careful consideration of various technical and environmental factors is essential. Below is a detailed guide on what to consider when placing an order.

1. Measurement Medium

The characteristics of the fluid or gas being measured directly influence the selection of the float flow meter. When specifying the medium:

- Type: Clearly identify whether the medium is a liquid, gas, or steam.

- Properties: Note any corrosive, viscous, or particulate characteristics. For corrosive fluids, materials like stainless steel, Hastelloy, or PTFE may be necessary.

- Purity: If the medium contains solid impurities, consider whether pre-filtration is required to prevent clogging.

2. Flow Rate Range

Float flow meters have specific operating ranges that should match your application. For optimal performance:

- Specify the minimum, maximum, and typical flow rates.

- Ensure the flow rate range falls within 30% to 70% of the meter’s full scale for the best accuracy.

- For highly variable flow conditions, consider a meter with a broader range or multiple units for different ranges.

3. Operating Conditions

The environmental and process conditions must be factored in to ensure long-term reliability:

- Pressure: Specify the working and maximum pressure to select a flow meter with appropriate pressure ratings.

- Temperature: Indicate the operating temperature range of the medium and environment. High temperatures may require special materials or additional thermal protection.

- Viscosity and Density: Provide detailed information about the medium’s physical properties, as these significantly affect the float’s behavior.

4. Installation Requirements

The installation method influences the meter’s design and connectivity options:

- Mounting Orientation: Most float flow meters are designed for vertical installation. If horizontal installation is needed, confirm compatibility.

- Pipe Size and Connections: Specify the pipe diameter and connection type (e.g., flange, threaded, or sanitary clamp). Ensure compatibility with existing piping.

- Upstream and Downstream Requirements: Allow for adequate straight pipe lengths to minimize turbulence and enhance accuracy.

5. Material Selection

The float flow meter’s construction materials must be compatible with the medium and operating environment:

- Measuring Tube Material: Options include glass, stainless steel, or plastic. Glass is suitable for low-pressure applications, while stainless steel is preferred for high-pressure or corrosive media.

- Float Material: Common materials include stainless steel, aluminum, or plastic, chosen based on density, corrosion resistance, and application requirements.

- Sealing Materials: Consider chemical compatibility when selecting seal materials like Viton, EPDM, or PTFE.

6. Indication and Signal Output

Determine how the flow rate information will be read and transmitted:

- Local Indication: A mechanical indicator on the meter itself may suffice for basic applications.

- Remote Monitoring: For automation or integration into a control system, specify signal output requirements (e.g., 4-20mA, pulse, or digital communication protocols like HART or Modbus).

- Alarm or Control Features: If needed, include options for alarms, switches, or feedback loops to enhance process control.

7. Special Features

Certain applications may require specialized features:

- Explosion-Proof Design: For hazardous environments, choose meters certified for ATEX, IECEx, or similar standards.

- High-Temperature or High-Pressure Resistance: For extreme conditions, verify that the selected model is rated for these parameters.

- Vibration Resistance: If the flow meter is installed in environments subject to vibrations, select one designed for mechanical stability.

8. Calibration and Accuracy

Flow meters are typically calibrated for a specific medium under defined conditions. To ensure accuracy:

- Provide details about the medium’s temperature, pressure, and density during normal operation.

- Request a calibration certificate or, if applicable, ask for in-situ calibration to meet stringent accuracy requirements.

9. Industry Standards and Certifications

Depending on your industry, certain standards or certifications may be mandatory:

- Common standards include ISO, CE, or UL certifications.

- For food, pharmaceutical, or biotech industries, ensure compliance with FDA, EHEDG, or GMP standards.

10. Vendor Selection and After-Sales Service

Choosing a reliable supplier ensures long-term support:

- Research the manufacturer’s reputation, focusing on their track record with similar applications.

- Confirm availability of spare parts and technical support.

- Inquire about installation guidance and warranty terms.

Key Information to Provide When Ordering

When contacting a supplier, prepare the following details to ensure the right flow meter is recommended:

- Medium: Type, corrosiveness, viscosity, and density.

- Flow Rate Range: Minimum, maximum, and normal operating ranges.

- Operating Conditions: Temperature and pressure specifics.

- Pipe Details: Diameter, material, and connection type.

- Special Requirements: Explosion-proofing, signal outputs, or industry standards.

By carefully evaluating these factors and providing clear specifications, you can ensure the selected float flow meter will meet your application requirements, deliver reliable performance, and enhance process efficiency.