Electromagnetic flow meters (often abbreviated as mag meters) are widely used for measuring the flow of conductive liquids and slurry. These devices operate based on Faraday’s Law of electromagnetic induction and are preferred for applications where traditional mechanical flow meters may fail due to issues like wear or the presence of solid particles in the fluid. Ensuring that the electromagnetic flow meter functions optimally requires correct installation, careful operation, and regular maintenance. Below is a detailed guide on the precautions and considerations during both usage and maintenance.

I. Precautions during Usage

1. Fluid Conductivity

Electromagnetic flow meters can only measure conductive fluids. For an accurate reading, the fluid must have a minimum conductivity, which is typically at least 5 µS/cm. If the fluid is non-conductive, such as oil or gas, the meter will not be able to measure the flow rate. Therefore, before installing an electromagnetic flow meter, always verify that the fluid being measured is conductive.

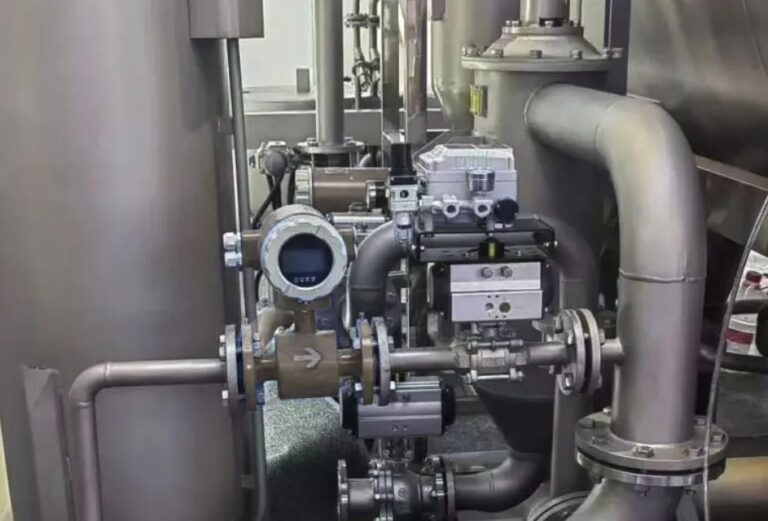

2. Correct Installation

Proper installation is crucial for the accurate performance of an electromagnetic flow meter. To minimize the risk of measurement errors, consider the following:

- Straight Pipe Installation: Ensure that the flow meter is installed in a straight section of the pipeline. The meter should ideally be placed in an area where the fluid flow is uniform and uninterrupted. Avoid installing the meter at bends, valve locations, or where there are changes in pipe diameter, as these can cause turbulence and inaccuracies.

- Minimum Straight Pipe Length: To ensure a stable and accurate flow reading, the flow meter should be installed with sufficient straight pipe sections both upstream and downstream. Typically, the recommended pipe length is five times the diameter of the pipe (5D) before and after the flow meter.

- Orientation: In many cases, the flow meter can be installed in any orientation (horizontal, vertical, or inclined), but it is generally recommended to install it with the electrodes in a horizontal position to prevent air pockets or sediment accumulation.

3. Flow Rate Compatibility

Before installing the flow meter, ensure that the flow rate of the fluid matches the meter’s measuring range. Each electromagnetic flow meter has a specified minimum and maximum flow rate that it can accurately measure. If the flow rate exceeds the maximum or drops below the minimum limit, the accuracy of the readings will be compromised. It is essential to match the meter’s capacity with the expected flow range in the pipeline.

4. Avoidance of Gas Bubbles or Air Locks

Electromagnetic flow meters are sensitive to the presence of air bubbles or gas pockets within the flow. If air is trapped inside the pipe, it can lead to significant errors in the measurement. Therefore, ensure that the system is properly vented, and the fluid entering the flow meter does not contain large amounts of entrained gas. This is especially important when measuring liquids like water, slurries, or any fluids that are prone to gas evolution.

5. Environmental Conditions

Electromagnetic flow meters should be used in an environment that aligns with their specifications. High humidity, extreme temperatures, or corrosive environments may affect their performance. The operating temperature and pressure conditions should always be checked against the manufacturer’s guidelines to avoid damaging the device. Additionally, some electromagnetic flow meters come with built-in protection for harsh environments, such as explosion-proof housings or IP (Ingress Protection) ratings, which should be verified during installation.

II. Precautions during Maintenance

1. Electrode Cleaning

Electrode contamination is one of the most common issues faced in electromagnetic flow meters. Over time, electrodes can accumulate scale, dirt, or other forms of deposit, especially when measuring fluids containing solid particles or chemicals. Regular cleaning of the electrodes is vital to maintain measurement accuracy. Depending on the fluid being measured, it may be necessary to clean the electrodes periodically using non-abrasive cleaning agents or a soft cloth. For highly corrosive fluids, the use of chemical cleaning agents may be required, but always refer to the manufacturer’s recommendations for suitable cleaning materials.

2. Checking Electrical Connections

Inspect all electrical connections at regular intervals to ensure they are secure and free from corrosion. A loose connection or damaged wiring can result in faulty signal transmission, leading to inaccurate readings or even system failures. Pay special attention to the connections at the signal output and power input terminals.

3. Power Supply and Battery Maintenance

Many electromagnetic flow meters are powered by batteries, while others rely on external power sources. If the meter runs on batteries, ensure they are replaced or recharged according to the manufacturer’s instructions. A low battery can result in inaccurate readings or even a complete failure of the device. For devices that rely on an external power supply, ensure that the voltage is stable and within the operational range of the meter. Voltage fluctuations can cause the meter to malfunction or produce incorrect data.

4. Calibration and Verification

Electromagnetic flow meters should be calibrated periodically to maintain their accuracy. Calibration involves comparing the flow readings from the meter to those from a standard flow measurement system under controlled conditions. If discrepancies are found, the meter may require adjustment or repair. In addition to factory calibration, field calibration may be necessary after significant changes in the system (e.g., pipe diameter changes, fluid composition shifts, or modifications to the measurement point).

5. Flow Sensor Inspection

Electromagnetic flow meters use a set of electromagnetic coils and sensors to detect the velocity of the fluid flow. Over time, these sensors can degrade due to exposure to harsh operating conditions, such as high temperatures, high pressure, or abrasive materials. Regularly inspect the sensors for wear and tear and replace them when necessary. Additionally, check for any blockages or deposits around the flow sensor that may impede the proper functioning of the meter.

6. Avoiding External Electromagnetic Interference

Electromagnetic flow meters rely on precise electromagnetic fields to measure flow rates. Therefore, strong external electromagnetic interference can cause signal distortion or inaccurate readings. Ensure that the flow meter is installed in an environment with minimal electrical noise. When installing the device in industrial settings with high levels of electromagnetic activity (e.g., near motors, power supplies, or electrical panels), consider using shielding or grounding techniques to protect the meter.

7. Software and Firmware Updates

Some modern electromagnetic flow meters are equipped with software and firmware that enable them to perform diagnostics, record data, and even adjust calibration settings remotely. It’s important to regularly check for software updates provided by the manufacturer. Updating the firmware may improve the meter’s functionality and accuracy or provide additional features that help with diagnostics and maintenance.

Conclusion

Electromagnetic flow meters offer a high level of accuracy and reliability in measuring conductive fluid flows, but like any measurement device, they require careful installation, proper operation, and routine maintenance to maintain their performance. By following the guidelines outlined above—paying attention to the fluid characteristics, ensuring proper installation, and performing regular maintenance tasks like cleaning electrodes and checking connections—you can ensure the long-term reliability and accuracy of your electromagnetic flow meter.

In any case of abnormal readings or potential faults, always consult the user manual or contact a professional technician for assistance. Regular calibration and appropriate maintenance practices will extend the lifespan of the flow meter and ensure that your measurement system remains precise and trustworthy.