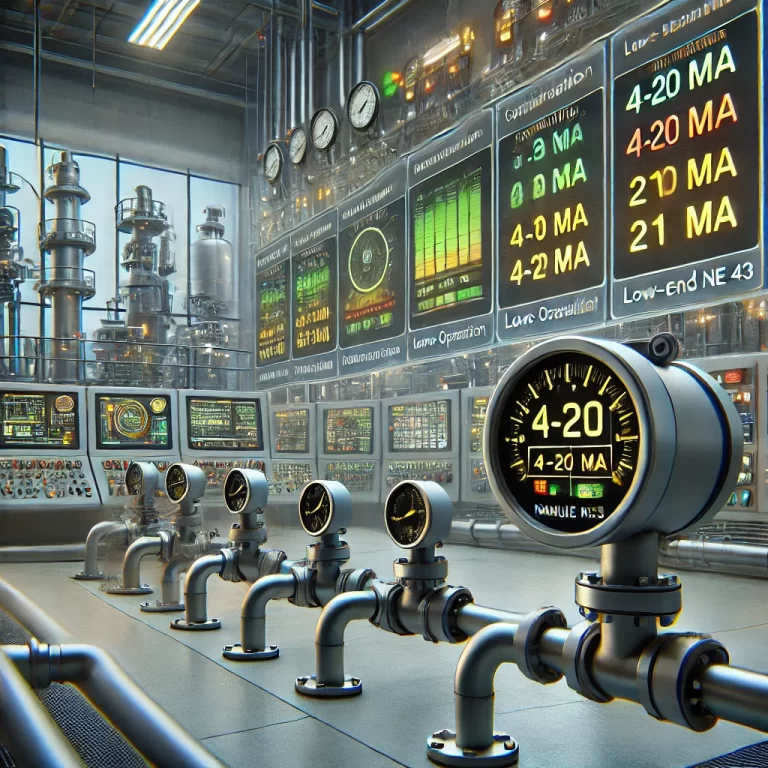

NAMUR NE 43 is a widely adopted signal standard in the field of industrial automation, primarily used for transmitting fault conditions and diagnostic information in process control instruments. This standard defines specific ranges within analog signals (typically 4 to 20 mA current signals) that indicate normal operating states and those that signify device faults or out-of-range conditions.

1. Origin of NAMUR NE 43

NAMUR (Normenarbeitsgemeinschaft für Mess- und Regeltechnik in der Chemischen Industrie) is a German association for standardizing measurement and control technology in the chemical industry. NE 43 is one of the recommended guidelines issued by NAMUR, aimed at addressing diagnostic issues in analog signal transmission. First introduced in 1990, the standard has since been widely adopted by numerous international standards organizations and equipment manufacturers.

2. Purpose and Benefits of NAMUR NE 43

NAMUR NE 43 defines a standardized signal range to clearly distinguish between normal measurement signals and fault conditions in 4-20 mA signals. Its primary purposes and benefits include:

Enhanced Fault Detection: Standardized current values effectively indicate the health status of devices, reducing unnecessary maintenance and downtime.

Improved System Reliability: Automatic detection of sensor or transmitter faults enhances overall system safety and reliability.

Support for Fail-Safe Design: Facilitates the easy identification of sensor open-circuit or short-circuit conditions, contributing to safer system designs.

3. Defined Signal Ranges in NAMUR NE 43

NAMUR NE 43 specifies the following signal ranges for fault detection and operational status:

3.8 – 4.0 mA: Lower limit of normal operation, typically used for low-end calibration.

4.0 – 20.0 mA: Normal operational range, representing 0% to 100% of the measured process variable.

20.0 – 20.5 mA: Upper limit of normal operation, used for high-end calibration.

<3.6 mA: Indicates a sensor open circuit or fault condition.

>21.0 mA: Signals a short circuit or device malfunction.

These clearly defined ranges allow automated systems to promptly detect and respond to abnormal conditions.

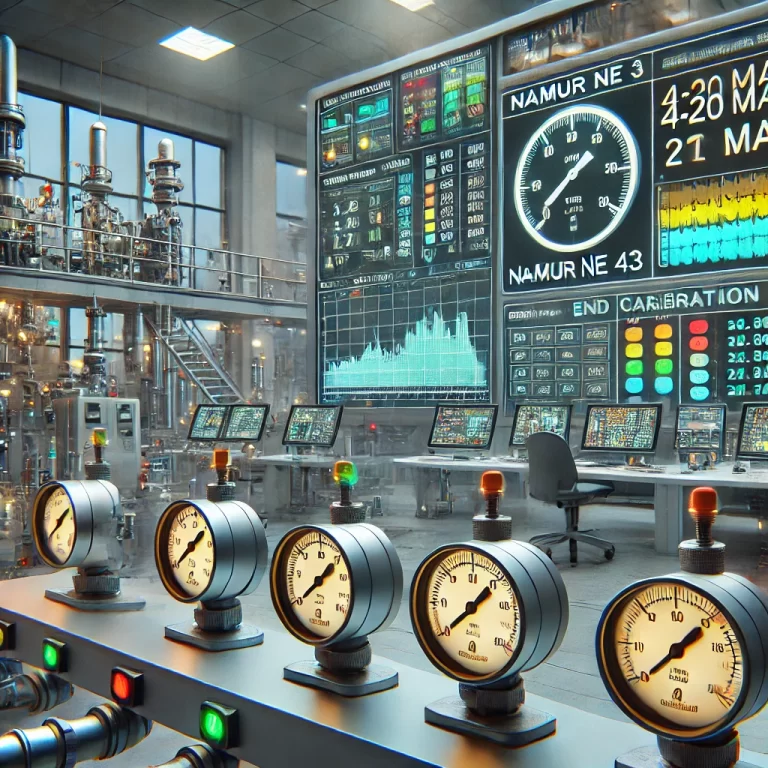

4. Practical Applications of NAMUR NE 43

Example 1: Pressure Transmitter

Under normal conditions, a pressure transmitter outputs a signal between 4-20 mA, corresponding to 0% to 100% of its measurement range.

If the sensor fails, the transmitter might output a signal below 3.6 mA, indicating a fault that requires maintenance.

Example 2: Temperature Transmitter

During normal temperature measurement, 20 mA represents the maximum measurable value.

If the measured temperature exceeds the preset range but the device remains functional, it may output a signal between 20 mA and 21 mA.

A signal above 21 mA signifies a device malfunction that demands immediate attention.

5. Extended Insights and Industry Impact

Standardization Advantage: The adoption of NAMUR NE 43 reduces the complexity of vendor-specific fault range definitions, enhancing interoperability among diverse devices and systems.

Fault Response Strategies: Control systems utilizing NAMUR NE 43 often include alarm configurations for timely responses to signal faults, effectively preventing process accidents.

Comparison with Other Standards: Compared to other industrial signal standards like IEC and ISA, NAMUR NE 43 offers a more comprehensive framework for diagnosing faults in analog signal transmission.

NAMUR NE 43 has become a foundational requirement in designing 4-20 mA industrial signal interfaces, playing a vital role in enhancing equipment reliability and operational safety across process industries.

Conclusion

NAMUR NE 43 serves as a critical standard in process automation, offering clear diagnostic capabilities and improving system safety and reliability. By defining precise signal ranges for normal operation and fault conditions, it empowers industries to implement proactive maintenance and fail-safe operations, solidifying its role as an essential standard in industrial automation.