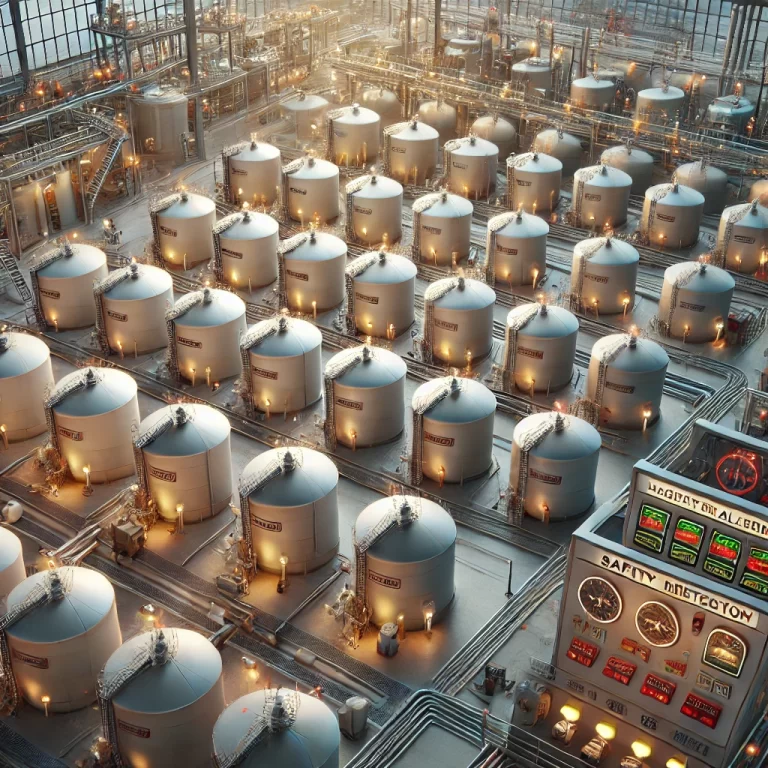

Storage tanks are critical components in various industrial processes, serving as vessels for storing raw materials, intermediates, and finished products. Due to the nature of substances stored, it is vital to implement safety interlocks to prevent accidents, environmental hazards, and equipment damage. This document provides a comprehensive overview of which storage tanks require interlocks and whether these interlocks should be integrated into an independent Safety Instrumented System (SIS).

Types of Storage Tanks Requiring Safety Interlocks

Flammable and Explosive Material Storage Tanks

Tanks storing substances like methanol, ethanol, gasoline, and diesel are highly flammable and pose significant explosion risks. These tanks must be equipped with interlocks that monitor high and ultra-high liquid levels, temperature, and pressure to prevent overflow, overpressure, and potential ignition sources.Toxic and Hazardous Material Storage Tanks

Tanks containing toxic substances such as liquid ammonia, chlorine, and hydrogen sulfide require interlocks to detect leaks, monitor gas concentration levels, and initiate emergency shutdown procedures. These measures are crucial to protecting personnel and the environment from exposure.High-Temperature and High-Pressure Storage Tanks

Tanks operating under extreme temperature and pressure conditions must have interlocks to control overpressure and overheating, which can lead to catastrophic failures if not adequately managed.Corrosive Material Storage Tanks

Storage tanks holding acids like sulfuric acid, hydrochloric acid, and hydrofluoric acid must include liquid level and leak detection interlocks. These systems help prevent structural damage and environmental contamination.Cryogenic Storage Tanks

Tanks storing liquefied natural gas (LNG), liquid nitrogen, and other cryogenic substances need specialized interlocks for pressure, temperature, and liquid level control to avoid rapid vapor expansion and potential explosions.

Typical Safety Interlock Functions

High-High Level (HHL) Interlock: Activates to prevent tank overflow, which can lead to spills and fires.

Low-Low Level (LLL) Interlock: Protects equipment like pumps from running dry, reducing wear and preventing damage.

Overpressure Protection: Triggers venting or shutdown procedures to avoid tank rupture.

Overtemperature Protection: Prevents thermal runaway reactions by shutting down heating systems or activating cooling mechanisms.

Leak Detection Interlock: Monitors for leaks at the base or perimeter of storage tanks, initiating containment or shutdown protocols.

Gas Detection Interlock: Detects the presence of toxic or flammable gases in the storage area and activates ventilation or evacuation systems.

Integration with Independent Safety Instrumented Systems (SIS)

Whether safety interlocks should be integrated into an independent SIS depends on the risk associated with the stored material and the potential consequences of system failure. The SIS is designed to execute safety functions independently of basic process control systems (BPCS) like Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC), providing a higher level of reliability and safety.

High-Risk Material Storage Tanks

For tanks storing flammable, explosive, or highly toxic materials, integrating interlocks into an independent SIS is strongly recommended. The SIS can autonomously trigger safety actions such as emergency shutdowns, venting, and deluge systems, ensuring rapid response in critical situations.Low-Risk Material Storage Tanks

Tanks containing non-hazardous materials like water or inert chemicals may not require integration with SIS. Standard DCS or PLC systems can manage safety controls effectively for these tanks.Large-Capacity or Complex Process Tanks

Storage tanks with significant capacity or involved in complex processes should be integrated with SIS, especially when a failure could lead to substantial safety, environmental, or economic impacts.

Advantages of SIS Integration

Operational Independence: SIS operates separately from DCS/PLC systems, reducing the risk of common-cause failures.

High Reliability: Complies with international safety standards such as IEC 61511 and IEC 61508, offering enhanced protection.

Fault Tolerance: Features self-diagnosis, fault isolation, and redundancy, ensuring consistent and reliable safety performance.

Conclusion

Implementing safety interlocks in storage tanks is a critical safety measure, especially for tanks storing hazardous materials. High-risk tanks should have their interlocks integrated into an independent SIS to provide robust and reliable protection. For low-risk tanks, standard control systems may suffice. A thorough risk assessment should guide the decision to integrate interlocks with SIS, balancing safety, operational efficiency, and cost-effectiveness.