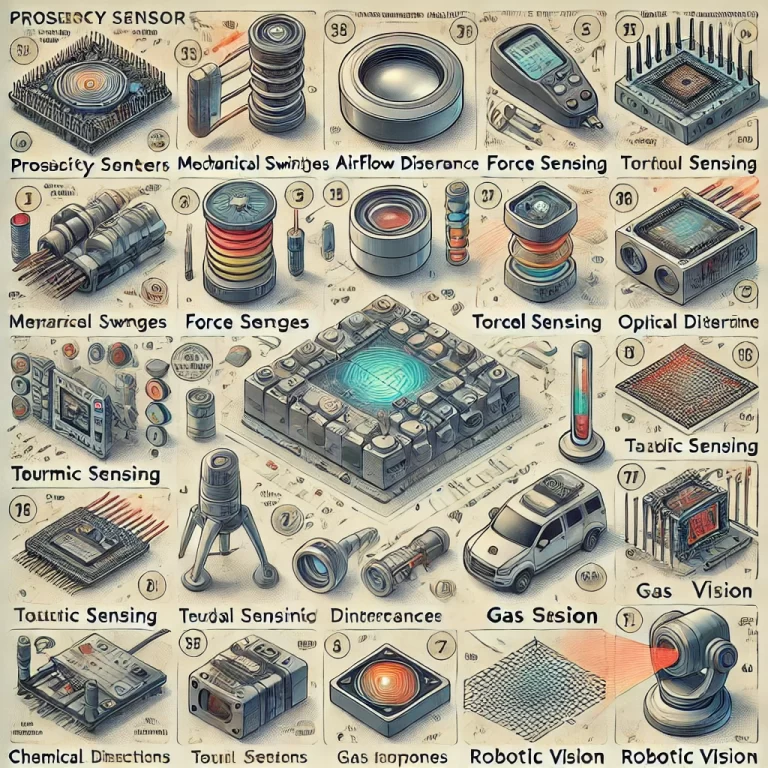

1. Proximity Sensing

Proximity sensing primarily involves detecting:

The presence or absence of an object.

The size or simple shape of an object.

Proximity sensors can be categorized into contact or non-contact types and can operate in analog or digital modes. The selection of sensors depends on physical, environmental, and control conditions. Common types include:

Mechanical Proximity Sensors: These use mechanical/electrical switches. Due to the need for physical force to operate mechanical switches, micro-switches are commonly used for enhanced sensitivity and durability.

Pneumatic Proximity Sensors: These sensors operate by disrupting or disturbing airflow. As contact sensors, they are unsuitable for detecting lightweight components that can be moved by air.

Optical Proximity Sensors: These sensors detect objects by interrupting a light beam that falls on a photosensitive device, such as a photodiode. They are non-contact sensors but are susceptible to environmental factors like dust, smoke, or welding flashes that can obscure the light path.

Electrical Proximity Sensors: These can be contact or non-contact. Contact types work by completing an electrical circuit, while non-contact types use induction to detect metals or capacitance to detect non-metals.

Distance Sensing: Distance sensors detect how close or far an object is from the sensor. Non-contact methods use capacitive, inductive, and magnetic technologies for short-range detection and emitted energy waves (radio waves, ultrasonic waves, and lasers) for long-range detection.

2. Force Sensing

Force sensing involves detecting six primary types of force, which can be static or dynamic:

Tension (Pulling Force)

Compression (Pushing Force)

Shear Force

Torsion (Twisting Force)

Bending Force

Friction Force

Tension Force: Measured indirectly using strain gauges, which detect resistance changes when stretched.

Compression Force: Measured using load cells that detect dimensional or pressure changes under load or resistance variations under compression.

Torsion Force: Considered a combination of tension and compression, measured using a combination of strain gauges and load cells.

Friction Force: Indirectly detected using a combination of force and motion sensors to analyze resistance to movement.

3. Tactile Sensing

Tactile sensing involves detecting through touch. The simplest tactile sensors use a matrix of touch-sensitive elements arranged in rows and columns. Each sensor activates upon contact, and by identifying active sensors (digital) or signal strength (analog), the size and shape of an object can be determined. Mechanical, optical, and electronic tactile sensors have been developed for various applications.

4. Thermal Sensing

Thermal sensing is vital for process control and safety monitoring. Different methods are chosen based on the temperature to be measured:

Bimetallic Strips: Used for simple temperature detection through mechanical bending.

Thermocouples: Measure temperature differences through voltage changes.

Resistance Temperature Detectors (RTDs): Use resistance changes in metal conductors.

Thermistors: Semiconductor devices that detect temperature through resistance variation.

Infrared Thermal Imagers: Used for detecting low-level heat sources in complex systems.

5. Acoustic Sensing

Acoustic sensors detect and sometimes distinguish various sounds, making them suitable for voice recognition and anomaly detection (e.g., explosions). The most common acoustic sensor is the microphone. In industrial settings, background noise can pose challenges. Tuning sensors to respond to specific frequencies allows differentiation between sounds.

6. Gas Sensing

Gas or smoke sensors detect specific gases by relying on chemical reactions in the sensor material. These reactions cause physical expansion or generate enough heat to trigger switching mechanisms. Gas sensors are crucial for safety and environmental monitoring.

7. Robotic Vision

Robotic vision is one of the most active research areas in sensor technology. It involves real-time image capture via cameras and converting these images into digital formats analyzable by computer systems. This process must be rapid to enable robots to respond and adapt during tasks.

Applications of robotic vision include:

Object presence, position, and motion detection.

Component recognition and identification.

Analysis of patterns, styles, and features.

Advanced robotic vision enhances industrial automation and artificial intelligence capabilities but requires significant memory and processing power.

By expanding and refining these sensor detection methods, this article provides a comprehensive understanding of various sensing technologies and their practical applications.