Flow measurement is a critical component in industrial processes, helping monitor and control the movement of liquids, gases, and steam. Two widely used flow measurement devices are Turbine Flow Meters and Vortex Flow Meters. While both serve the purpose of flow measurement, they operate on fundamentally different principles and are suitable for distinct applications. This article provides a detailed comparison between these two types of flow meters, highlighting their working principles, advantages, disadvantages, and typical use cases.

Working Principle

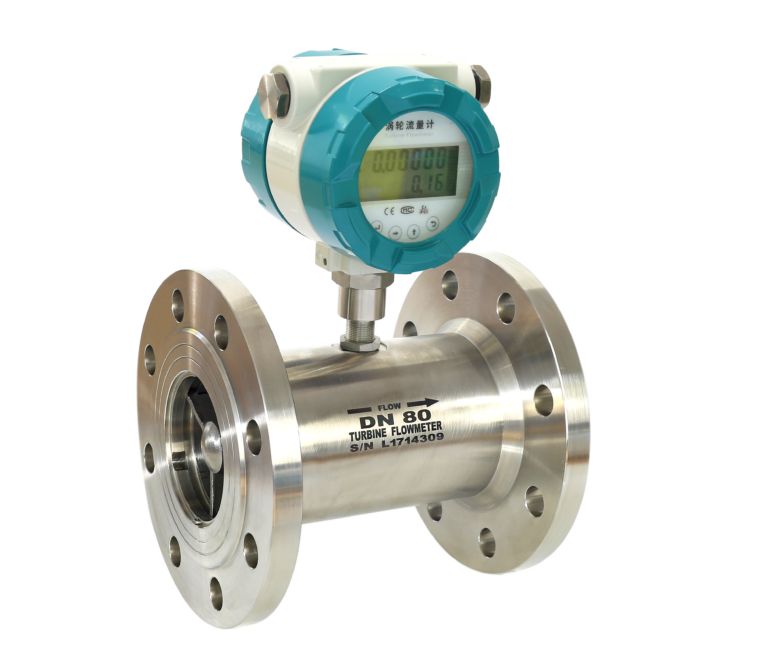

Turbine Flow Meter: Turbine flow meters operate based on the mechanical rotation of a rotor or impeller within the fluid stream. As the fluid flows through the meter, it causes the rotor blades to spin. The rotational speed of the rotor is directly proportional to the velocity of the fluid. A magnetic or optical sensor detects the rotor’s rotation and converts it into electrical pulses, which are then used to calculate the flow rate.

Vortex Flow Meter: Vortex flow meters function on the principle of the Karman vortex street. When a fluid passes through a bluff body (a non-streamlined object) placed in the flow path, it creates alternating vortices downstream. The frequency of these vortices is proportional to the flow velocity. Sensors detect the vortex shedding frequency and convert it into a flow rate measurement.

Suitable Fluids and Conditions

Turbine Flow Meter: Turbine flow meters are best suited for clean, low-viscosity liquids and gases. They perform exceptionally well with fluids like water, light oils, and natural gas. However, they are not ideal for fluids with high viscosity or those containing particulates, as these can damage the rotor or impede its movement.

Vortex Flow Meter: Vortex flow meters have a broader range of applications. They can measure the flow of liquids, gases, and steam. They are particularly advantageous in handling aggressive, high-temperature, and high-pressure fluids, making them suitable for steam, compressed air, and various chemical applications. Vortex meters are less sensitive to fluid impurities compared to turbine meters.

Accuracy and Performance

Turbine Flow Meter: Turbine flow meters are known for their high accuracy, typically within ±0.2% to ±0.5%. However, their accuracy can be affected by changes in fluid viscosity, flow profile disturbances, and mechanical wear of the rotor.

Vortex Flow Meter: Vortex flow meters generally offer an accuracy of around ±1% to ±1.5%. While slightly less precise than turbine meters, they provide stable performance across a wide range of flow rates and are less influenced by temperature and pressure changes.

Maintenance and Durability

Turbine Flow Meter: Due to their moving parts, turbine flow meters require regular maintenance. The rotor and bearings can wear out over time, especially when measuring aggressive or particulate-laden fluids. Regular calibration and part replacement are necessary to maintain accuracy.

Vortex Flow Meter: Vortex flow meters have no moving parts, resulting in minimal maintenance requirements. Their robust design ensures durability and long-term stability, even in harsh operating environments. This feature makes them more cost-effective over time compared to turbine meters.

Typical Applications

Turbine Flow Meter:

Chemical processing for clean liquid measurement

Water treatment facilities

Fuel measurement in aviation and automotive industries

Natural gas distribution

Vortex Flow Meter:

Steam flow measurement in power plants

Compressed air monitoring in manufacturing

Chemical and petrochemical industries

HVAC systems for energy management

Advantages and Disadvantages

Turbine Flow Meter: Advantages:

High measurement accuracy

Quick response to flow changes

Suitable for clean, low-viscosity fluids

Disadvantages:

Requires regular maintenance due to moving parts

Not suitable for dirty or viscous fluids

Sensitive to flow disturbances

Vortex Flow Meter: Advantages:

Suitable for liquids, gases, and steam

Minimal maintenance due to no moving parts

Resistant to temperature and pressure changes

Disadvantages:

Slightly lower accuracy than turbine meters

Not ideal for very low flow rates

Conclusion

Choosing between a turbine flow meter and a vortex flow meter depends on the specific requirements of the application. For clean, low-viscosity fluids requiring high precision, turbine flow meters are ideal. In contrast, vortex flow meters offer greater versatility and durability, making them better suited for challenging conditions involving steam, gas, or mixed-phase fluids. Understanding the operational environment and maintenance capabilities is key to selecting the most effective flow measurement technology.