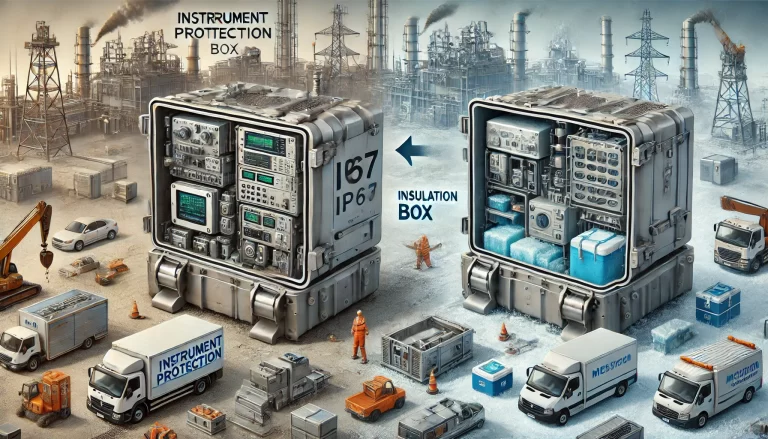

In industrial, laboratory, and outdoor environments, instrument protection boxes and insulation boxes serve critical but distinct purposes. While both are designed to protect their contents, they differ significantly in terms of functionality, materials, design priorities, and application scenarios. This article will explore the differences between these two types of boxes and provide insight into their unique applications.

📊 1. Key Differences Between Instrument Protection Boxes and Insulation Boxes

| Feature/Aspect | Instrument Protection Box | Insulation Box |

|---|---|---|

| Primary Function | Protect instruments from physical damage, dust, moisture, and corrosion. | Maintain internal temperature to prevent temperature-sensitive items from spoiling or being damaged. |

| Material | Stainless steel, carbon steel, aluminum alloy, reinforced plastic. | Polyurethane foam, EPP (Expanded Polypropylene), food-grade plastic. |

| Thermal Insulation | Minimal thermal insulation, though some models may offer basic insulation features. | Excellent thermal insulation to stabilize internal temperature. |

| IP Rating (Ingress Protection) | Often rated IP65 or IP67 for dustproof, waterproof, and corrosion-resistant capabilities. | Usually not rated for IP standards, focus is on temperature maintenance. |

| Internal Contents | Instruments, sensors, controllers, and measurement devices. | Food, vaccines, biological samples, chemical reagents. |

| Temperature Control | Primarily designed for physical protection, less focus on temperature regulation. | Often equipped with temperature control devices or thermal materials. |

| Application Scenarios | Industrial environments, power plants, chemical plants, automated control systems. | Medical transportation, food delivery, laboratory sample storage. |

| Mobility | Typically fixed in place, though some portable models exist. | Usually portable for ease of transport and mobility. |

🛡️ 2. Instrument Protection Box: Purpose and Applications

Instrument protection boxes are primarily designed to safeguard sensitive electronic and mechanical equipment from environmental factors such as dust, moisture, extreme temperatures, and chemical exposure. These boxes are most commonly used in industrial and outdoor settings, where precision instruments must operate reliably in challenging environments.

2.1 Applications of Instrument Protection Boxes

Industrial Automation Systems:

- Protect Programmable Logic Controllers (PLCs), sensors, and control panels.

- Ensure uninterrupted operation of automation systems in factories.

Chemical Plants:

- Shield measurement and control instruments from corrosive gases and liquids.

- Prevent chemical contamination from damaging sensitive equipment.

Power Generation Facilities:

- House temperature and pressure sensors.

- Ensure reliable performance in high-temperature or high-pressure environments.

Outdoor Monitoring Stations:

- Protect environmental monitoring equipment from rain, dust, and temperature fluctuations.

- Commonly used in weather stations and pollution monitoring systems.

2.2 Design Features of Instrument Protection Boxes

- IP Ratings: Often rated IP65 or IP67 to provide robust protection against dust and water ingress.

- Viewing Windows: Transparent sections allow operators to monitor instruments without opening the box.

- Corrosion Resistance: Constructed from materials like stainless steel or specially coated alloys for durability.

- Mounting Options: Wall-mounted, floor-standing, or pole-mounted designs depending on the installation site.

2.3 Advantages of Instrument Protection Boxes

- Prolongs the lifespan of sensitive instruments.

- Reduces maintenance and replacement costs.

- Provides security in hazardous environments (e.g., explosive or corrosive areas).

❄️ 3. Insulation Box: Purpose and Applications

Insulation boxes, on the other hand, are primarily designed to maintain stable internal temperatures, protecting their contents from environmental temperature fluctuations. These boxes are widely used in sectors like medical transportation, food distribution, and laboratories.

3.1 Applications of Insulation Boxes

Medical Transportation:

- Safely transport vaccines, blood samples, and temperature-sensitive medications.

- Maintain required temperatures using ice packs or active temperature control systems.

Food Delivery and Catering:

- Preserve the freshness of perishable food items.

- Maintain hot or cold temperatures for ready-to-eat meals during delivery.

Laboratory Use:

- Store and transport biological samples and chemical reagents.

- Prevent damage or degradation caused by temperature fluctuations.

Outdoor Activities and Emergency Situations:

- Used in camping, hiking, and outdoor adventures to store food and medications.

- Serve as emergency kits for disaster relief containing temperature-sensitive supplies.

3.2 Design Features of Insulation Boxes

- Insulating Materials: High-quality polyurethane foam or expanded polypropylene (EPP) ensures excellent thermal performance.

- Temperature Control Mechanisms: Equipped with ice packs, heat pads, or electronic cooling/heating systems.

- Portability: Lightweight designs with ergonomic handles and wheels for easy transport.

- Sealed Lids: Airtight seals to prevent temperature leaks.

3.3 Advantages of Insulation Boxes

- Ensures product integrity during transportation.

- Reduces spoilage and financial loss.

- Portable and user-friendly designs enable flexible usage.

🔄 4. Key Takeaways: Which One to Choose?

Choose an Instrument Protection Box if:

- You need to protect sensitive electronic or mechanical instruments from harsh environmental factors.

- Your focus is on durability, weather resistance, and equipment safety.

Choose an Insulation Box if:

- You need to maintain specific temperature ranges for items such as food, medicine, or biological samples.

- Your priority is portability and efficient thermal insulation.

📝 5. Final Thoughts

While both instrument protection boxes and insulation boxes serve protective functions, their designs are fundamentally different due to their unique purposes. Instrument protection boxes excel in shielding valuable equipment from physical and environmental damage, while insulation boxes are designed to maintain temperature-sensitive contents in optimal conditions.

Understanding their differences and respective strengths can help industries, laboratories, and transportation services make informed decisions, ensuring the safety and integrity of their valuable assets.