Introduction

In the realm of industrial automation, the Modbus protocol is highly regarded for its simplicity and broad applicability. For engineers and technicians, understanding the size of a Modbus frame is not merely a theoretical pursuit but a critical consideration in practical applications. The frame size directly influences communication efficiency, system response times, and network bandwidth utilization. This article delves into the specifics of Modbus frame size and its implications for real-world use cases.

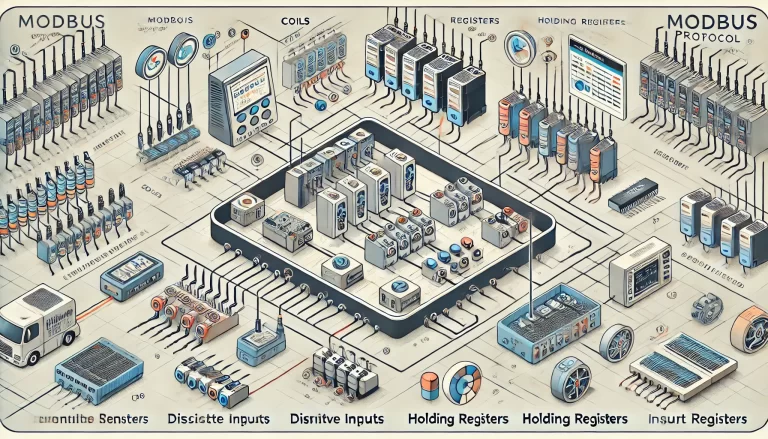

Modbus RTU Frame Structure Overview

To grasp the frame size constraints of Modbus RTU (Remote Terminal Unit), it is essential to understand its structure. A standard Modbus RTU frame consists of four key components:

Device Address:

Occupies 1 byte.

Identifies the intended device, with a range of 0 to 255.

Function Code:

Occupies 1 byte.

Specifies the operation to be performed, such as reading or writing registers.

Data Field:

Variable in length, ranging from 0 to 252 bytes.

Contains the actual data, such as register addresses and values, depending on the function.

CRC (Cyclic Redundancy Check):

Occupies 2 bytes.

Ensures data integrity by verifying the frame’s correctness.

When combined, these components form a complete Modbus RTU frame, with a theoretical maximum size of 256 bytes (1 + 1 + 252 + 2).

Maximum Frame Size: Theory vs. Practice

While the theoretical maximum frame size is 256 bytes, practical implementations often impose additional constraints. These limitations are introduced to enhance communication reliability, reduce error rates, and optimize processing speeds. For instance, many systems restrict frame sizes to 127 bytes or less, especially in environments with high interference or limited bandwidth.

Example: Modbus RTU Communication

Let us consider a specific example to illustrate how frame size impacts communication:

Scenario:

A master device requests data from a sensor by reading two consecutive input registers (30008 and 30009).

Request Frame:

Device Address:

0x02(target device ID)Function Code:

0x04(read input registers)Starting Address:

0x0007(hexadecimal for 30008 minus the base address 30001)Number of Registers:

0x0002CRC: Calculated from the preceding fields

The total size of the request frame is 8 bytes.

Response Frame:

Device Address:

0x02Function Code:

0x04Byte Count:

0x04(2 registers × 2 bytes each)Register Data: Actual values of the requested registers

CRC: Calculated from all preceding fields

The total size of the response frame is 12 bytes, assuming no additional error-checking or padding is added.

Why Frame Size Matters

Communication Efficiency: Larger frames allow for more data to be transmitted in a single transaction, reducing overhead. However, excessively large frames may lead to higher error rates and retransmissions.

System Performance: Smaller frames can improve response times in time-sensitive applications, especially when multiple devices share the same network.

Network Constraints: In bandwidth-limited environments, managing frame size is critical to ensure stable and efficient communication.

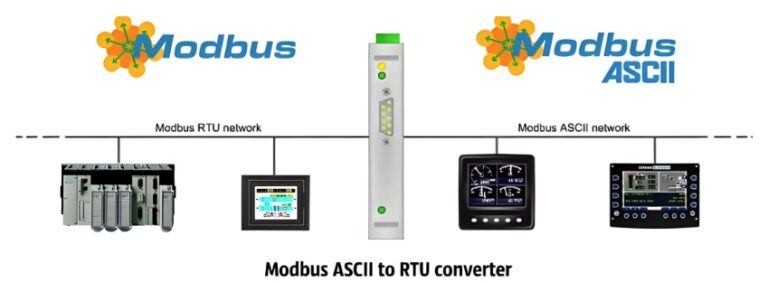

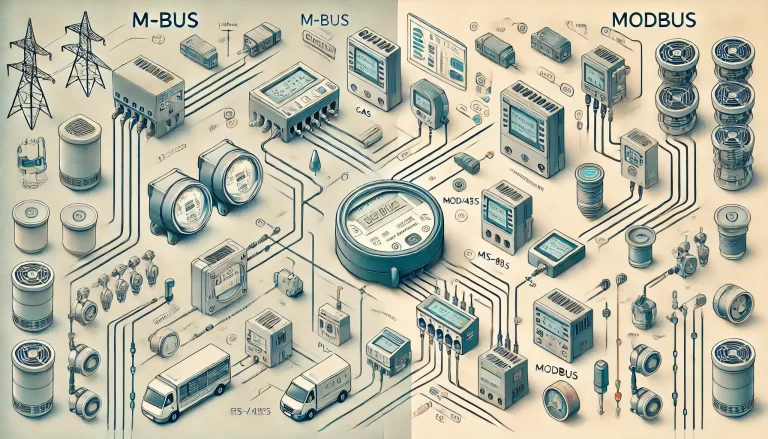

Beyond Modbus RTU: Variants and Considerations

While this article focuses on Modbus RTU, other Modbus variants, such as Modbus TCP, have different frame size constraints and design considerations. For example, Modbus TCP frames can be larger due to their reliance on Ethernet-based communication, which offers higher bandwidth and lower latency.

Optimizing Frame Sizes in Practice

To achieve optimal performance, consider the following best practices:

Assess Environmental Conditions: Adjust frame size limits based on interference levels and network reliability.

Balance Data Volume and Frequency: When transmitting large datasets, divide them into smaller, manageable frames to minimize errors.

Leverage Protocol Features: Use function codes and data fields efficiently to maximize payload while staying within recommended size limits.

Conclusion

Although Modbus RTU frames can theoretically reach 256 bytes, practical constraints often dictate smaller sizes to balance efficiency, reliability, and performance. Understanding these nuances is essential for professionals in industrial automation, enabling them to design robust communication systems tailored to specific requirements. As technology evolves, future innovations may further enhance the flexibility and efficiency of Modbus and similar protocols.