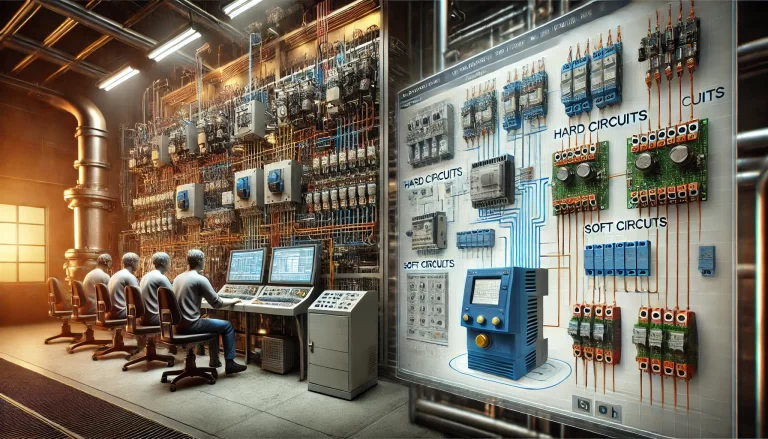

In modern industrial systems, the concepts of “hard circuits” and “soft circuits” (or “hard wiring” and “soft wiring”) are commonly used to describe different methods of implementing logic control and protection functionalities. Understanding these distinctions is crucial for system design, operation, and maintenance. Below is a detailed explanation of their definitions, characteristics, and applications.

1. Definitions

Hard Circuits

Hard circuits refer to logic control and protection functionalities implemented through physical wiring, including relays, manual buttons, and other electromechanical components. These circuits are independent of computerized systems and are primarily designed to ensure system safety and functionality even when distributed control systems (DCS) fail.

Example: Emergency shutdown systems often use hard circuits to ensure reliable operation during critical conditions.

Soft Circuits

Soft circuits, on the other hand, rely on programmable controllers, computers, or DCS systems to implement logic control through software configurations. The functionality of soft circuits is achieved through code and programming instructions, allowing for greater flexibility and scalability compared to hard circuits.

Example: Process interlocks implemented within a DCS system to coordinate various subsystems.

2. Characteristics

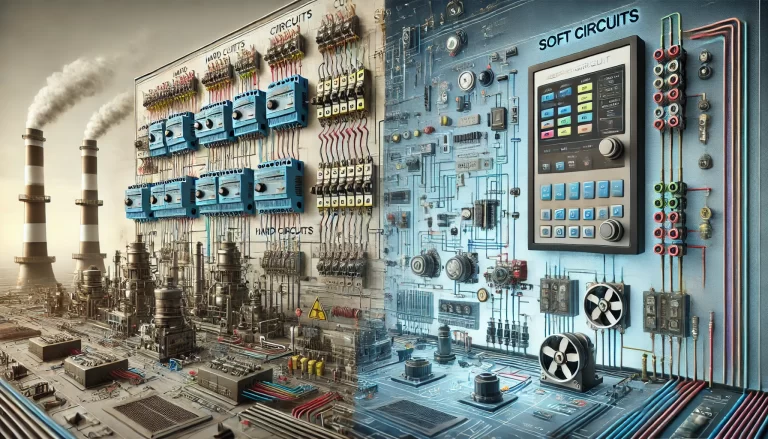

Hard Wiring

Visibility: Physical wiring is tangible, with visible terminals and test points, making troubleshooting straightforward.

Direct Transmission: Signals are transmitted directly through wiring without intermediate processing. For instance, a signal from a switch activates a relay immediately.

Reliability: Often considered more reliable for safety-critical applications due to its independence from software failures.

Traditional Technology: Represents conventional control methods widely used before the advent of advanced control systems.

Soft Wiring

Programmable: Soft wiring relies on software-based logic, providing a high degree of flexibility to modify and expand the system.

Intermediate Logic: Actions are executed based on programmed instructions, which can incorporate conditions, delays, and complex logic.

Integration: Easily integrates with modern systems such as sensors, actuators, and remote communication networks.

Reduced Physical Complexity: Eliminates extensive wiring, reducing installation time and physical complexity.

3. Practical Applications

Hard Wiring Examples

Direct Signal Actions: Used in systems like oil pump startups, vacuum breaker valves, or remote shutdown switches. For instance, pressing a button to open a vacuum breaker valve immediately actuates the valve without intermediary systems.

Safety Systems: Emergency stop buttons or fail-safe mechanisms that must operate reliably without depending on software.

Soft Wiring Examples

Process Interlocks: When a specific condition is met, the DCS executes programmed logic to trigger a series of actions, such as shutting down equipment or activating alarms.

Automation Logic: Advanced systems that rely on real-time data processing and complex interdependencies, such as temperature control loops in a chemical plant.

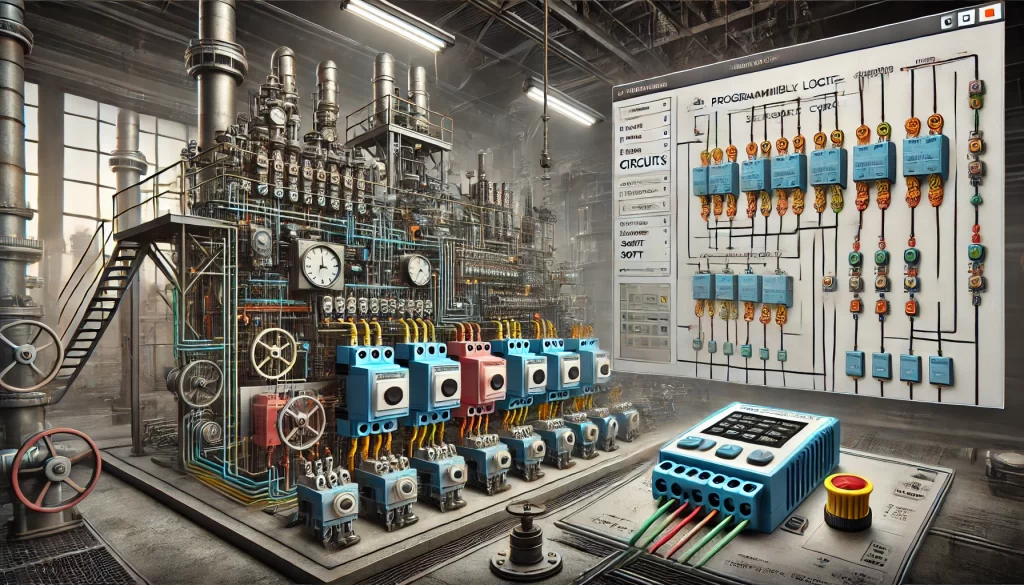

4. Hard Interlocks vs. Soft Interlocks

In DCS terminology, interlocks can be categorized as hard or soft based on their implementation:

Hard Interlocks

Achieved through direct wiring and relay logic.

Actions occur independently of the DCS.

Example: A relay-based shutdown system for a high-pressure boiler.

Soft Interlocks

Implemented via DCS programming, where conditions are evaluated in software, and corresponding actions are triggered.

Example: A DCS program monitors pump discharge pressure and stops the pump if pressure exceeds a safe threshold.

Note: While the terms “hard interlock” and “soft interlock” are common, the standard terminology often uses “hard connection” and “soft connection” to emphasize the method of implementation.

5. Considerations for System Design

When deciding between hard circuits and soft circuits, consider the following factors:

Reliability: For critical safety functions, hard circuits are preferred due to their independence from software or communication failures.

Flexibility: Soft circuits allow for easier modifications, scalability, and integration with complex systems.

Cost: Hard wiring may require more physical components and installation effort, while soft wiring reduces hardware but may involve higher programming costs.

Maintenance: Hard circuits are easier to troubleshoot due to their physical visibility, but soft circuits provide diagnostic tools within the DCS.

6. Conclusion

Both hard circuits and soft circuits have their strengths and are indispensable in modern industrial systems. Hard circuits offer unmatched reliability for safety-critical applications, while soft circuits provide flexibility and ease of integration. Understanding the distinctions and selecting the appropriate method based on system requirements ensures optimal performance, safety, and cost-effectiveness.