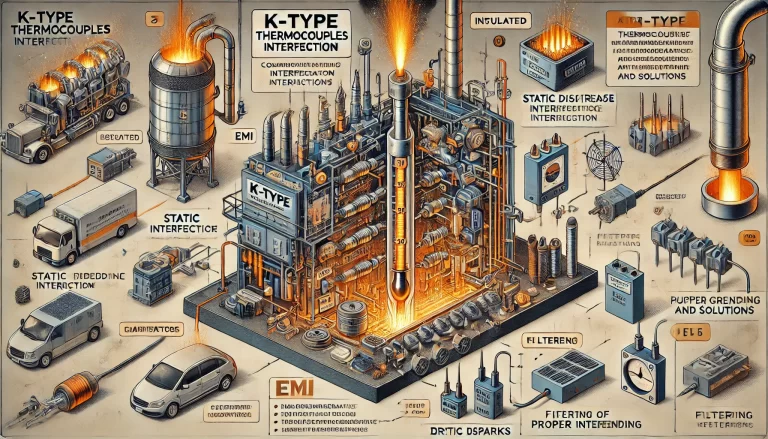

1. Introduction

K-type thermocouples are widely used in industrial and laboratory settings for temperature measurement due to their robustness and broad operating temperature range. However, their measurement accuracy can be significantly affected by various forms of interference. This article outlines the common sources of interference, effective solutions, and practical case studies to help professionals mitigate these issues in real-world applications.

2. Common Sources of Interference

2.1 Electromagnetic Interference (EMI)

Electromagnetic fields generated by nearby equipment, such as motors, transformers, and variable frequency drives, can induce noise in the thermocouple signal, leading to inaccurate measurements.

2.2 Static Interference

In dry environments, static electricity can accumulate. If a potential difference exists between the thermocouple and nearby objects, static discharge can interfere with the thermocouple’s normal operation and destabilize its signals.

2.3 High-Temperature Leakage Interference

At elevated temperatures, the insulation performance of the thermocouple’s materials may degrade, causing leakage currents to interfere with the signal. This issue is particularly pronounced near refractory bricks or other insulating materials in high-temperature furnaces.

2.4 Ground Loop Interference

Ground loops occur when multiple devices or instruments have different ground potentials, creating unwanted currents in the signal circuit. This can distort the thermocouple readings significantly.

3. Solutions to Interference Issues

3.1 Isolation Techniques

Physical Isolation: Install the thermocouple in a suspended manner to avoid direct contact with insulating materials like refractory bricks. Use insulating materials between the thermocouple and its mount to prevent high-temperature leakage interference.

3.2 Shielding Techniques

Shielded Cabling: Encapsulate the thermocouple’s compensation wires in metal shielding, such as iron pipes or other conductive materials, to block external electromagnetic fields.

Proper Grounding: Ensure that the metal shielding is securely grounded to enhance its effectiveness. Additionally, twist the compensation wires to minimize electromagnetic coupling.

3.3 Grounding Techniques

Reference Junction Grounding: Connect one end of the thermocouple or its compensation wire to a large capacitor and ground it. This helps redirect interference signals to the ground.

Measurement End Grounding: Attach a high-temperature-resistant and compatible metal wire to the thermocouple’s measurement end and ground it to prevent high-temperature leakage currents.

3.4 Filtering Techniques

Hardware Filtering: Install filters, such as low-pass, high-pass, or band-pass filters, at the signal output or amplifier input to suppress high-frequency noise. Choose the appropriate filter based on the frequency characteristics of the interference.

Software Filtering: Use digital filtering algorithms, such as Infinite Impulse Response (IIR) or Finite Impulse Response (FIR), to process the captured data and eliminate noise.

3.5 Proper Compensation Wire Selection and Wiring

Compensation Wire Selection: Use compensation wires that match the thermocouple type and are rated for the appropriate temperature range. For example, KX compensation wires are suitable for -20°C to 100°C, while wider-range wires can handle -25°C to 200°C.

Wiring Guidelines: Keep compensation wires away from power lines and other potential interference sources. Where crossing is unavoidable, ensure the crossing occurs at right angles rather than parallel runs. Limit wire lengths to 15 meters; if longer distances are necessary, use a temperature transmitter for signal transmission.

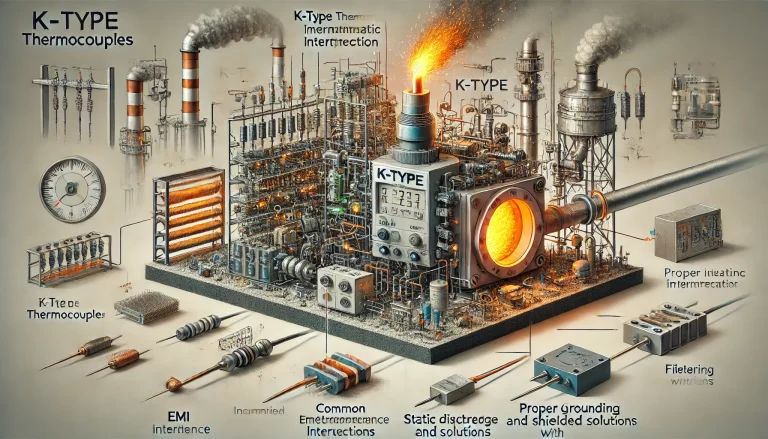

4. Practical Case Studies

4.1 Interference in Oven Temperature Measurement

Problem: In a mechanical temperature-controlled oven using a K-type thermocouple, heating elements caused significant interference, resulting in unstable temperature readings.

Solution: A 10µF electrolytic capacitor was connected across the thermocouple’s input, combined with digital filtering (IIR or FIR algorithms) in the control software. These measures stabilized the readings.

4.2 Interference in High-Temperature Furnace with PID Control

Problem: In a high-temperature furnace experiment, a thermocouple connected to a DAQ card caused rapid fluctuations in readings when temperatures approached 1000K, affecting other thermocouples on the same DAQ card.

Solution: Investigations revealed that interference followed the high-temperature thermocouple. Solutions included optimizing grounding and shielding of signal lines, resolving the interference and ensuring accurate temperature readings.

4.3 Securing High-Temperature K-Type Thermocouples

Problem: High-temperature thermocouples, such as PK-1000 models, had issues with insulation and fixation at elevated temperatures. Previous attempts with plastic shrink tubing or ceramic adhesives failed under extreme conditions.

Solution: A chromium-nickel alloy wire, matching the thermocouple’s material, was used to tightly secure ceramic fibers near the thermocouple’s tip. This approach ensured stability and accurate readings without compromising the thermocouple’s performance.

5. Recommendations for Avoiding Interference

5.1 Proper Installation and Selection

Choose compatible compensation wires and limit their length.

Avoid parallel runs with power lines and other interference sources.

5.2 Isolation and Shielding

Suspend the thermocouple to prevent contact with high-temperature insulating materials.

Use shielded cables with proper grounding.

5.3 Grounding and Filtering

Implement grounding techniques as appropriate for the specific interference type.

Use both hardware and software filtering for optimal results.

6. Conclusion

By understanding the sources of interference and implementing effective mitigation techniques, professionals can significantly improve the accuracy and reliability of K-type thermocouple measurements. This article provides a comprehensive guide to tackling common interference issues, equipping practitioners with practical solutions for real-world applications.