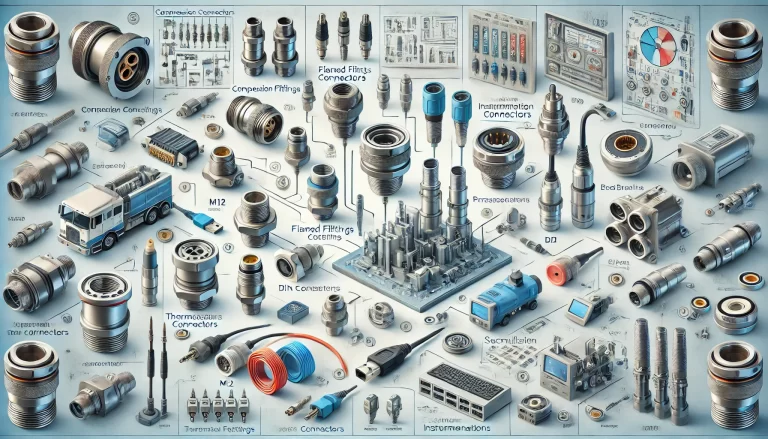

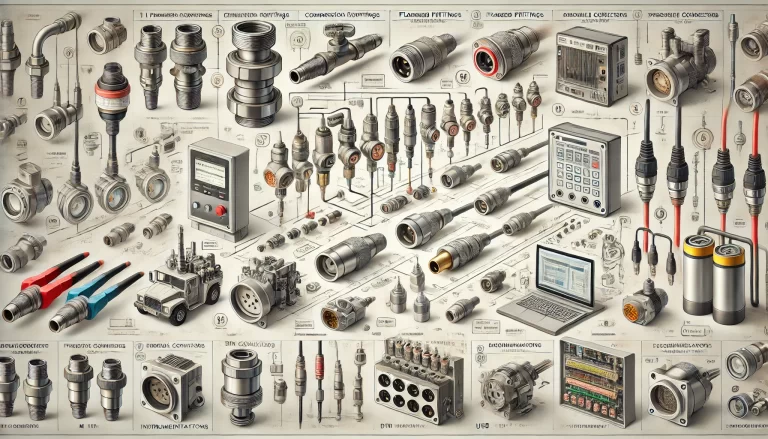

In the field of instrumentation, connectors are vital components ensuring seamless communication, power delivery, and fluid/gas transfer. Choosing the right connector can improve system performance, reliability, and safety. This article delves into the various types of connectors, their applications, and some popular models widely used in the industry.

1. Piping Connectors (Fluid and Gas Transmission)

Piping connectors are crucial in fluid and gas systems to ensure leak-proof connections and reliable operation under varying pressure and temperature conditions.

1.1 Compression Fittings

- Applications: Widely used in gas and liquid pipelines for connecting tubing and valves in instrumentation systems.

- Features: No need for welding; provides reliable sealing and ease of installation.

- Popular Models:

- Swagelok Series: SS-400-6 (1/4″ OD, stainless steel), SS-810-6 (1/2″ OD, stainless steel)

- Parker CPI Series: 4F-C6L-SS (1/4″, stainless steel)

1.2 Flared Fittings

- Applications: Suitable for high-pressure liquid systems, such as hydraulic or pneumatic applications.

- Features: Offers robust connections through a flared end of the pipe, minimizing leakage risks.

- Popular Models:

- Parker 37° Flare Fittings

- Eaton Aeroquip Flared Fittings

1.3 Quick Connect Couplings

- Applications: Used in systems requiring frequent connection/disconnection, such as maintenance-intensive setups.

- Features: Quick and easy plug-and-play mechanism with strong sealing performance.

- Popular Models:

- FESTO Quick Star Series (Push-in Connectors)

- Swagelok QC Series

2. Electrical Connectors (Signal and Power Transmission)

Instrumentation relies heavily on electrical connectors to transmit data and power between components in a robust and efficient manner.

2.1 M12 Connectors

- Applications: Industrial automation and sensor networks for power and signal transmission.

- Features: Compact design, IP67-rated (waterproof and dustproof), suitable for harsh environments.

- Popular Models:

- Phoenix Contact: 1404418 (5-pin, A-coded, male plug)

- TE Connectivity: M12 Series with shielded and unshielded options

2.2 DIN Connectors

- Applications: Frequently used for solenoid valves and pressure sensors.

- Features: Standardized design with variants like DIN 43650 A, B, and C, ensuring compatibility across devices.

- Popular Models:

- Hirschmann GDM Series

- Amphenol DIN Series

2.3 Circular Aviation Plugs

- Applications: Transmitting multiple signals in rugged environments like aerospace, military, and industrial applications.

- Features: Vibration-resistant, durable, and available in various pin configurations.

- Popular Models:

- GX Series: GX16-5 (16mm, 5 pins), GX12-4 (12mm, 4 pins)

- Amphenol Circular Connectors

3. Specialized Instrumentation Connectors

These connectors are tailored for specific applications, ensuring precise data capture and transfer in critical instrumentation systems.

3.1 Thermocouple Connectors

- Applications: Connecting thermocouples to instrumentation systems, ensuring accurate temperature readings.

- Features: Constructed from thermocouple-compatible materials to prevent signal degradation.

- Popular Models:

- Omega Miniature Connectors: SMPW-K (Type K thermocouple, compact design)

- OSTW-K: Standard thermocouple connectors for laboratory and industrial use

3.2 Pressure Instrumentation Connectors

- Applications: Connecting pressure transmitters and gauges in fluid systems.

- Features: Typically threaded designs, resistant to high pressures and corrosive environments.

- Popular Models:

- NPT (National Pipe Thread): 1/4″-18 NPT, 1/2″-14 NPT

- G Thread (British Standard Pipe): G1/4, G1/2

4. Communication Connectors (Data Transmission)

Modern instrumentation systems often include digital communication for real-time monitoring and control.

4.1 RJ45 Connectors

- Applications: Ethernet-based communication systems, such as industrial networks and SCADA.

- Features: High-speed data transmission with shielded or unshielded options.

- Popular Models:

- Phoenix Contact: 2744572 (Cat5e, shielded industrial RJ45)

4.2 USB Connectors

- Applications: Connecting instrumentation devices to computers or data acquisition systems.

- Features: Universal compatibility and ease of connection.

- Popular Models:

- USB Type A (standard computers)

- USB Type B (printers, industrial devices)

- USB Type C (modern high-speed devices)

Connector Selection Tips

- Identify Application Requirements: Consider the medium (fluid, gas, signal), pressure/temperature ratings, and environmental conditions.

- Check Compatibility: Ensure connector compatibility with tubing, sensors, or instruments.

- Consider Future Scalability: Opt for modular and easy-to-replace connectors to accommodate future upgrades.

- Choose Reputable Brands: Trusted manufacturers like Swagelok, Parker, Phoenix Contact, and Omega offer proven reliability.

Conclusion

Instrumentation connectors play a pivotal role in ensuring the seamless operation of industrial systems. By understanding the different types and their applications, engineers can select the most suitable connectors for their specific needs, enhancing system performance, reliability, and safety. Whether you’re working with fluid pipelines, electrical systems, or digital communication networks, the right connectors are key to success in instrumentation.