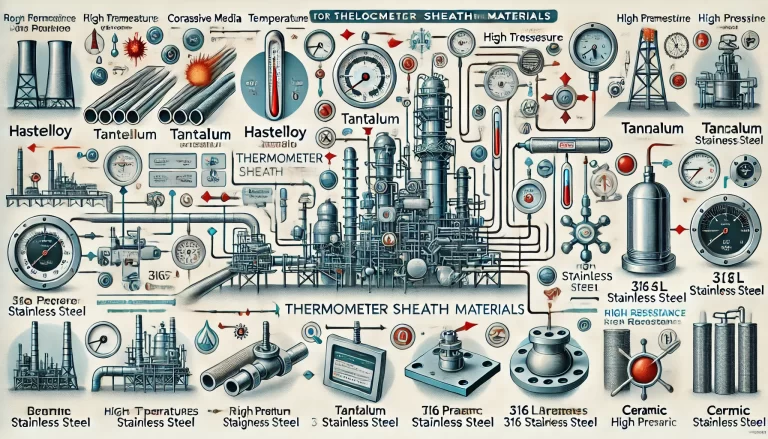

In chemical plants, the installation of temperature measuring instruments such as thermometers and temperature transmitters often requires careful consideration of the thermometer sheath (TW). Since the sheath comes into direct contact with the medium, the material selection must align with the characteristics of the medium—be it corrosive, flammable, or explosive—to ensure stable operation and meet production requirements.

Key Considerations for Material Selection

When selecting the material for a thermometer sheath in a chemical plant, multiple factors should be considered:

1. Nature of the Measured Medium

Corrosive Media: For strongly acidic media such as hydrochloric acid, Hastelloy or tantalum sheaths are preferred. Hastelloy is highly resistant to various corrosive substances, while tantalum offers excellent corrosion resistance, particularly against hydrochloric acid.

Alkaline Media: 316L stainless steel is suitable due to its strong resistance to alkaline environments.

2. Temperature

High Temperatures: In environments exceeding 800°C, ceramic sheaths are recommended due to their high-temperature resistance and thermal stability.

Low Temperatures: Standard stainless steel sheaths are generally sufficient for low-temperature applications.

3. Pressure

High-Pressure Environments: Alloy steel sheaths, known for their high strength, are required to withstand significant pressure and prevent sheath rupture.

4. Mechanical and Environmental Conditions

For media containing solid particles or exhibiting high flow rates, abrasion-resistant sheaths should be used to minimize wear and tear.

The insertion depth of the sheath must ensure that the temperature sensing element’s tip is located within the medium’s temperature-sensitive region. For pipelines, the insertion depth should range between one-third and one-half of the pipe’s diameter, with a minimum insertion of 50mm.

Standards and Guidelines

The following standards provide detailed guidance on thermometer sheath selection:

1. SH/T 3005-2016 “Design Specification for Selection of Petrochemical Automation Instruments”

Material Selection: Sheath materials should meet temperature measurement range requirements, corrosion resistance, and erosion resistance. The minimum standard is 316SS, and the material should be at least as robust as the pipeline or equipment it is used with.

Structure and Design: Single-end integral drilled conical sheaths are preferred. For low-temperature and low-pressure media, thick-walled secondary-formed sheaths are acceptable.

Connection Methods: Flange connections are preferred. When flange connections are not allowed, socket weld connections can be used. For non-hazardous media (e.g., water, air, nitrogen) in low-pressure pipelines (CL150 or below), threaded connections are permissible.

Special Applications: In environments with high temperature, pressure, or flow, vibration frequency and stress calculations should conform to the ASME PTC 19.3 TW standard. Adjustments should be made if the sheath structure or material fails to meet these requirements.

2. HG/T 20507-2014 “Design Specification for Automation Instrument Selection”

Protective sheaths should be integral drilled conical types, especially for high-temperature and high-pressure media.

For surface or ambient temperature measurement, protective sheaths are not required. Armored or assembled temperature elements are recommended.

3. SY/T 7700-2023 “Design Specification for Instrumentation and Control Systems in Oil and Gas Field and Pipeline Projects”

Sheath materials should be selected based on the medium’s temperature, pressure, corrosion, and erosion properties. The material’s performance must not be inferior to that of the pipeline or equipment.

Flange-type protective sheaths are suitable for equipment installations, while flanged, welded, or threaded types are used for pipeline installations depending on the medium’s properties and operating conditions.

Summary

Material selection for thermometer sheaths should be tailored to the specific project’s requirements and the medium characteristics. For closed sheaths, used in pressurized and flammable environments, robust materials like alloy steel or Hastelloy are essential. For non-hazardous or routine applications, open sheaths with standard stainless steel can suffice. Following industry standards ensures reliability, safety, and operational efficiency in temperature measurement applications.