Introduction

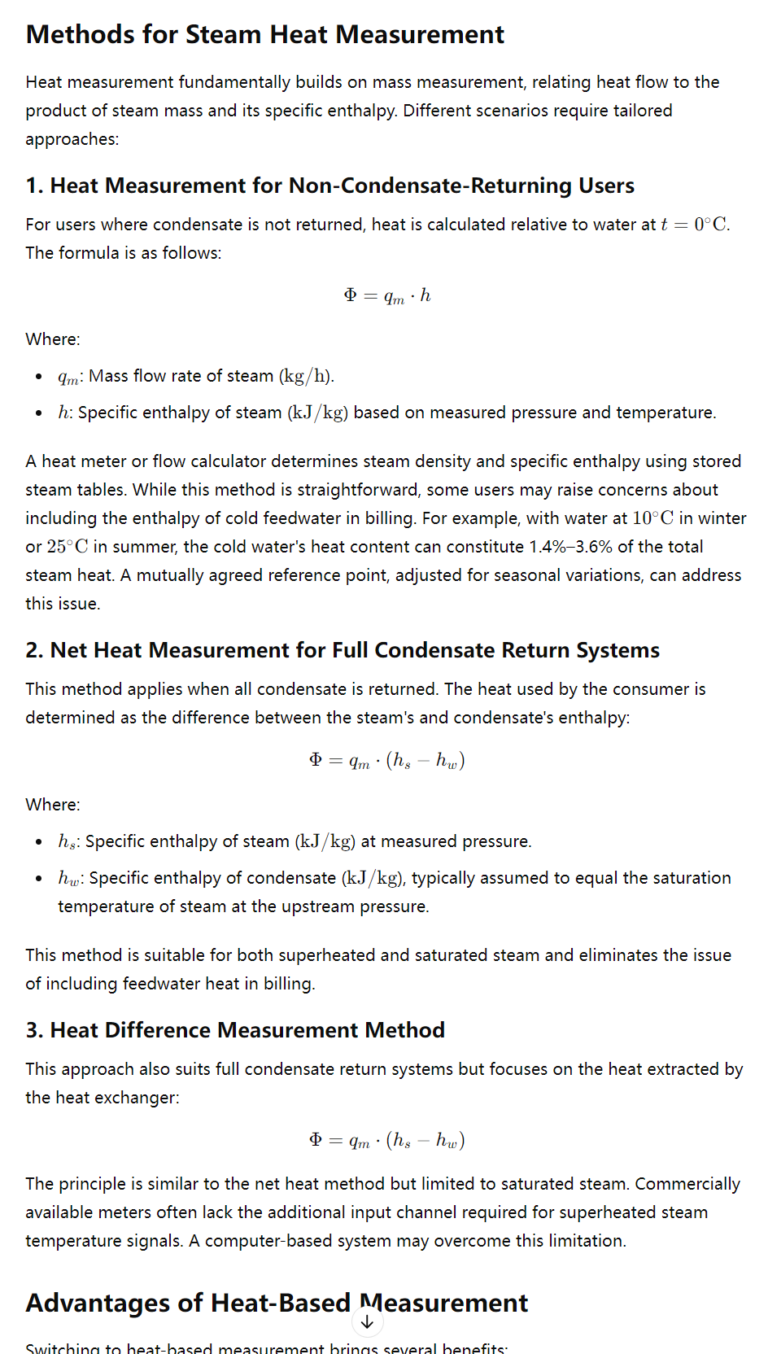

Traditionally, steam trade settlements relied on mass measurement due to limited technological capabilities. Both domestically and internationally, this approach was widely accepted despite long-standing questions about its fairness. The preference for mass measurement stemmed from its simplicity compared to the more complex heat measurement methods, especially when analog instruments dominated the landscape.

With advancements in computer technology, the development of flow meters now makes both steam mass and heat measurement straightforward, ushering in the transition from mass-based to heat-based metrics. This shift addresses key fairness concerns and improves the precision of energy exchange calculations in steam systems.

Challenges with Steam as a Heat Carrier

Steam is one of the most widely used heat carriers, but it faces significant challenges during generation and transportation. Variations in pressure and temperature are inevitable, causing fluctuations in specific enthalpy (the heat content per unit mass of steam). For instance:

- At the outlet of a pressure reduction station, steam might exhibit conditions like p=0.9 MPa(A) and t=280∘C, corresponding to a specific enthalpy of 3012.0 kJ/kg.

- Upon reaching the end user, this steam may degrade to saturated steam at p=0.8 MPap, reducing the specific enthalpy to 2767.5 kJ/kg.

These variations in steam conditions, influenced by seasonal changes, weather, and load fluctuations, disproportionately affect end users. Under a mass-based measurement system, end users at the far end of the network often pay for lower-quality steam, creating a fairness issue.

Additionally, suppliers face inefficiencies. To guarantee promised steam quality, suppliers must include a margin for quality assurance, leading to revenue losses. Heat-based measurement resolves these issues by incorporating both quantity and quality into the billing process, ensuring fairness for both parties.

Advantages of Heat-Based Measurement

Switching to heat-based measurement brings several benefits:

- Fairness: Combines steam quality and quantity, resolving unfair billing practices.

- Efficiency: Reduces supplier losses from overcompensating for quality margins.

- Accuracy: Reflects real energy exchanges, particularly valuable in variable conditions.

Conclusion and Recommendations

Steam heat measurement methods offer precise, fair, and practical solutions for modern energy trade systems. To ensure successful implementation:

- Standardize reference points: Mutually agree on water reference temperatures to avoid disputes.

- Adopt advanced instruments: Leverage computer technology for handling complex scenarios like superheated steam.

- Incorporate visual aids: Use diagrams and flowcharts to clarify system setups and measurement methods.

By addressing these considerations, steam heat measurement can transform the way energy is valued and traded, benefiting suppliers and users alike.