Types of Errors

Reference Error:

- Definition: Reference error is the ratio of absolute error to the measurement range, expressed as a percentage.

- Formula: Reference Error (%) = (Absolute Error / Measurement Range) × 100

Absolute Error:

- Definition: The difference between the measured result and the true value.

- Formula: Absolute Error = Measured Value – True Value

Relative Error:

- Definition: The ratio of absolute error to the measured value, expressed as a percentage.

- Formula: Relative Error (%) = (Absolute Error / Measured Value) × 100

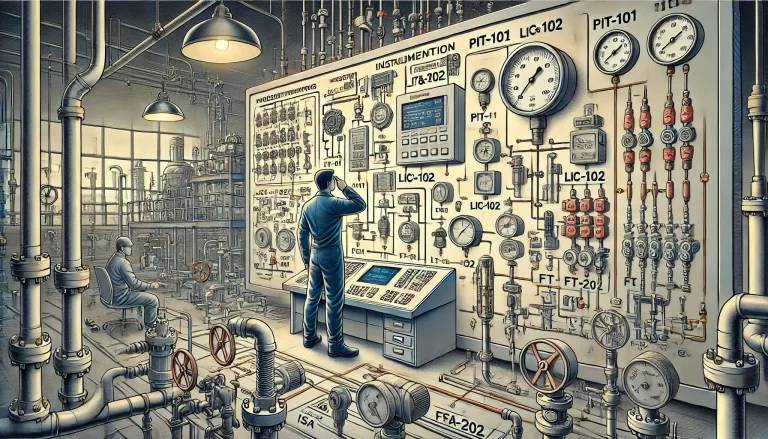

Instrument Accuracy Grades

Instrument accuracy grade, also known as accuracy level, is classified based on the maximum permissible error as per national standards. The accuracy grade provides a standardized way to evaluate an instrument’s precision and reliability.

- Formula: Accuracy Grade (%) = (Maximum Absolute Error / Instrument Range) × 100

- Grades: Common grades are 0.1, 0.2, 0.5, and 1.0.

- Grade 0.1: Highest precision, smallest error.

- Grade 1.0: Lowest precision, largest error.

Importance of Accuracy and Error in Instruments

Definition of Error: Errors reflect the difference between an instrument’s displayed value and the actual measured value. High-precision instruments exhibit smaller errors and higher approximation to the true value.

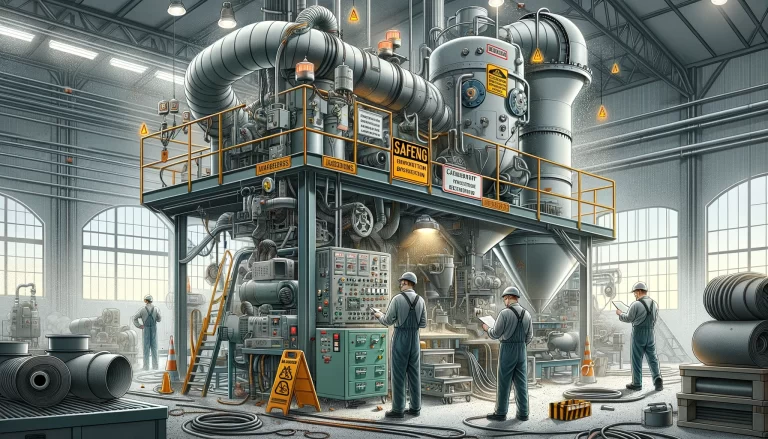

Practical Applications of Instrument Accuracy

Industrial Production:

- High-accuracy instruments, such as precise thermometers in pharmaceutical manufacturing, ensure optimal quality and safety of products.

Scientific Research:

- Accurate measurement tools are crucial in experiments where precision directly impacts data validity and experimental outcomes.

Engineering Measurement:

- Reliable instruments help prevent costly errors in construction and manufacturing processes.

Examples and Practical Demonstration

Example of Calculating Reference Error:

- A thermometer has a measurement range of 100°C and shows a 0.5°C absolute error.

- Reference Error (%) = (0.5 / 100) × 100 = 0.5%

- This indicates that the thermometer is within an acceptable tolerance level for industrial use.

Illustration of Accuracy Grades:

- Consider a pressure gauge classified as 0.2 grade. If the range is 200 units, the maximum permissible error is 0.2% of 200, equating to ±0.4 units.

Key Considerations for Choosing Instruments

- Application Needs: Select accuracy grades based on the precision required in specific industries.

- Cost vs. Benefit: Balance the need for accuracy against the cost of high-precision instruments.

- Environment: Consider external factors such as temperature, humidity, and vibrations that might impact measurement accuracy.

Conclusion

Understanding the concepts of errors and accuracy in instruments is fundamental for ensuring measurement reliability in various applications. With precise calculations and informed instrument choices, industries and researchers can significantly reduce operational risks and enhance the quality of their outcomes.